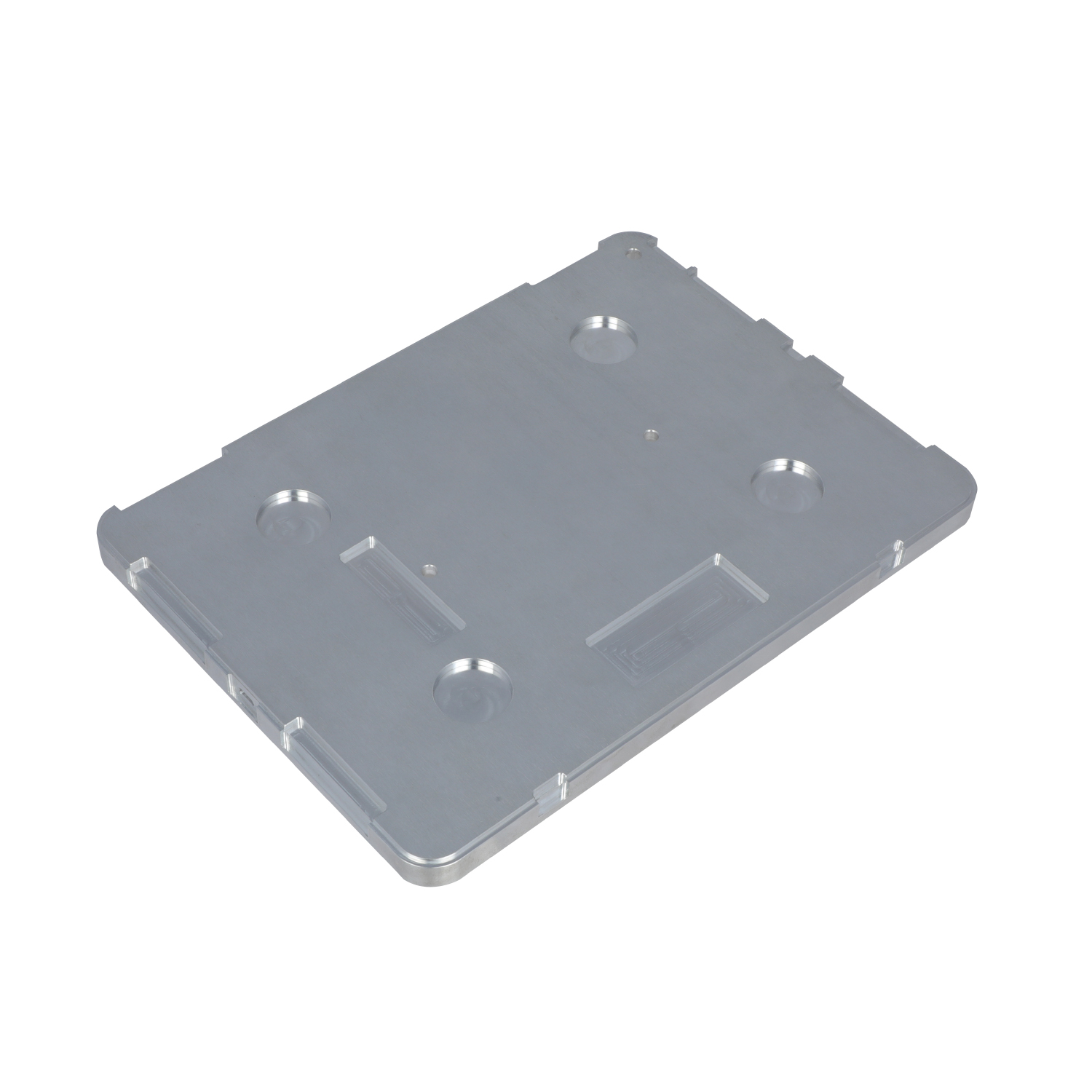

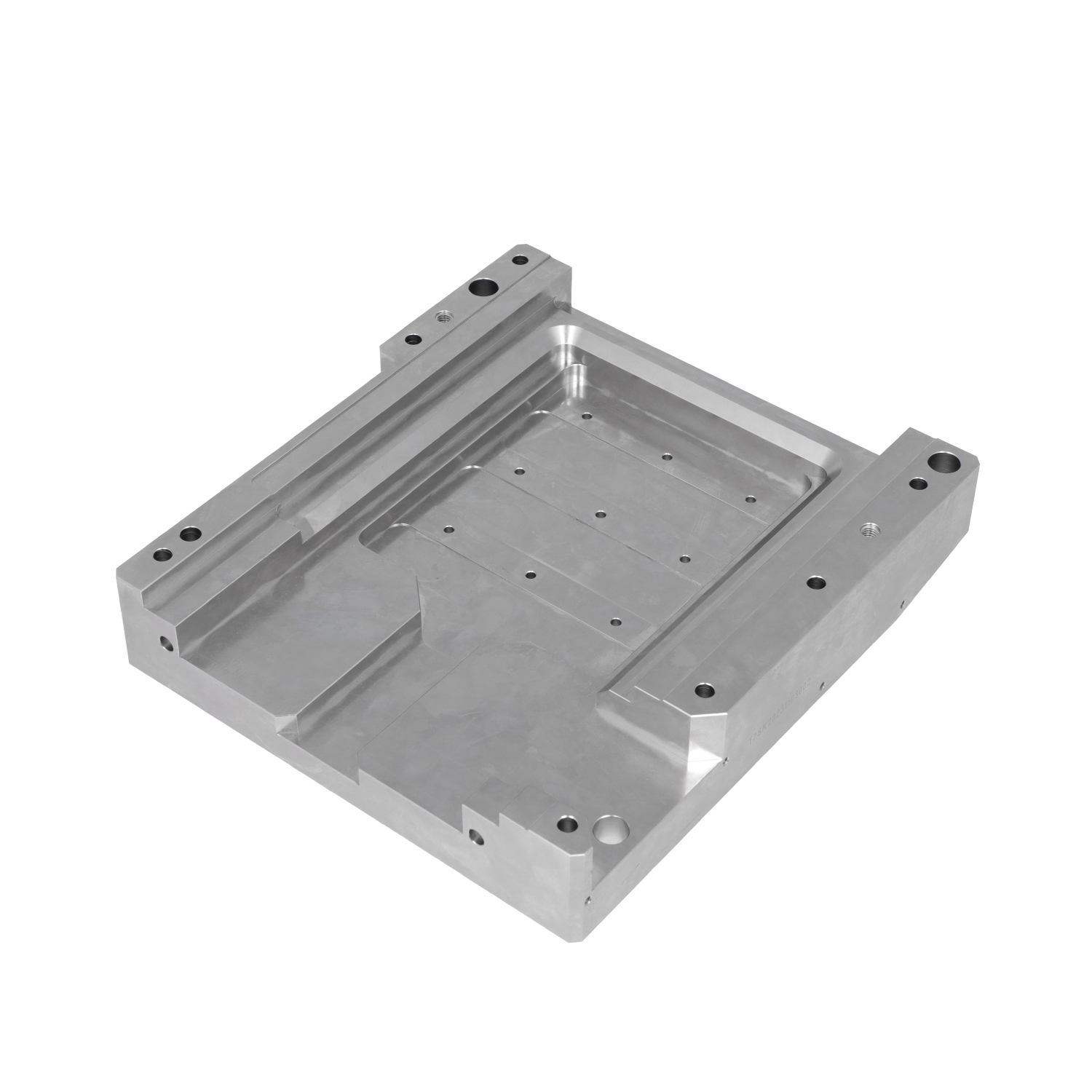

CNC Factory Machining Enclosure

Material: 45 steel,aluminum alloy,stainless steel, plastic,brass

Processing techniques: CNC, EDM, turning, five axis machining, stamping,hobbing, milling, grinding, drilling, tapping, reaming, pulling, cutting, etc

Finish:Polishing, painting, anodizing,sandblasting, plating ,blackening, electrophoresis, QPQ ,wire drawing

- Product Description

Dongguan Junsion Precision Hardware Co., Ltd: Your Trusted CNC Factory Machining Enclosure Partner

At Dongguan Junsion Precision Hardware Co., Ltd, we specialize in manufacturing high-quality CNC factory machining enclosures for diverse industries. Our state-of-the-art facilities and expert team ensure precision-engineered solutions that meet your exact specifications. With our advanced CNC technology, we deliver enclosures with tolerances up to ±0.01mm, guaranteeing consistent accuracy and reliability for your critical components.

Description

Our products are the perfect solution for protecting sensitive equipment in various industrial applications. We offer a wide range of customizable options to suit your specific needs:

Materials:

- Aluminum (6061-T6, 7075)

- Stainless Steel (304, 316)

- Carbon Steel

- Titanium

Sizes:

- Custom dimensions available

- Standard sizes from 50mm x 50mm x 25mm to 1000mm x 1000mm x 500mm

Features:

- Precision-machined for optimal fit and function

- Customizable mounting options

- IP-rated designs for dust and water resistance

- EMI/RFI shielding capabilities

- Thermal management solutions

| Material | 1) Aluminum: AL 6061-T6, 6063, 7075-T etc. |

| 2) Stainless steel: 303,304,316L, 17-4(SUS630) etc. | |

| 3) Steel: 4140, Q235, Q345B,20#,45# etc. | |

| 4) Titanium: TA1,TA2/GR2, TA4/GR5, TC4, TC18 etc. | |

| 5) Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc. | |

| 5) Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc. | |

| Finish | Sandblasting, Anodize color, Blackenning, Zinc/Nickl Plating, Polish. |

| Power coating, Passivation PVD, Titanium Plating, Electrogalvanizing. | |

| Electroplating chromium, electrophoresis, QPQ(Quench-Polish-Quench). | |

| Electro Polishing,Chrome Plating, Knurl, Laser etch Logo, etc | |

| Main Equipment | STEP,STP,GIS,CAD,PDF,DWG,DXF etc or samples. |

| Tolerance | +/-0.01mm ~ +/-0.05mm |

| Surface roughness | Ra 0.1~3.2 |

| Inspection | Complete inspection lab with Micrometer, Optical Comparator, Caliper Vernier,CMM. |

| Depth Caliper Vernier, Universal Protractor, Clock Gauge, Internal Centigrade Gauge | |

| Capacity | CNC turning work range: φ0.5mm-φ150mm*300mm. |

| CNC milling work range: 510mm*1020mm*500mm. |

Surface Treatment

We offer various surface treatment options to enhance the performance and aesthetics of your products:

- Anodizing (Type II and III)

- Powder coating

- Electroplating (Nickel, Chrome, Gold)

- Sandblasting

- Brushing

- Polishing

Our expert team can recommend the best surface treatment based on your application requirements and environmental conditions.

Drawing Guide

To ensure we meet your exact specifications, we accept various file formats for your CNC factory machining enclosure designs:

- 2D drawings: DWG, DXF, PDF

- 3D models: STEP, IGS, X_T, PRT

- Samples for reverse engineering

Our engineering team can assist with design optimization and material selection to enhance performance and reduce costs.

Production Process

- Design Review and Optimization

- Material Sourcing and Inspection

- CNC Machining (Milling, Turning, Drilling)

- Deburring and Cleaning

- Surface Treatment

- Quality Control Inspection

- Assembly (if required)

- Packaging and Shipping

Quality Certification

We maintain strict quality control measures throughout our production process:

- ISO 9001:2015 Certified

- RoHS Compliant

- REACH Compliant

- 100% In-house Quality Inspection

Our advanced testing equipment, including 2.5D projectors and hardness testers, ensures that every product meets or exceeds industry standards.

Shipping and Delivery

We understand the importance of timely delivery in your production schedule. Our efficient logistics network allows us to offer:

- Sample delivery within 3 days

- Mass production orders within 7-15 days

- Flexible shipping options (air, sea, express)

- Secure packaging to prevent damage during transit

Why Choose Us?

- Advanced Precision Machining: Our state-of-the-art CNC equipment ensures unparalleled accuracy.

- Customization Expertise: We work closely with you to create tailored solutions.

- Material Variety: Wide selection of high-quality, RoHS-compliant materials.

- Fast Turnaround: Quick sample and production times to meet your deadlines.

- Strict Quality Control: Comprehensive testing and inspection processes.

- Global Experience: Trusted by 500+ clients worldwide across various industries.

- Customer-Centric Approach: Transparent communication and responsive service.

FAQ

Q: What is the minimum order quantity (MOQ) for the products?

A: Our MOQ varies depending on the complexity and size of the enclosure. For standard designs, we typically have an MOQ of 50 units. For custom projects, we can accommodate smaller quantities.

Q: Can you provide prototypes before mass production?

A: Yes, we offer prototyping services to ensure your product meets all specifications before moving to full production.

Q: What industries do you typically serve?

A: We serve a wide range of industries, including electronics, telecommunications, medical equipment, automotive, and industrial automation.

Q: Do you offer assembly services for components within the enclosures?

A: Yes, we can provide assembly services for internal components upon request.

Contact & Support

Ready to discuss your CNC factory machining enclosure needs? Our team is here to help!

Email: Lock@junsion.com.cn, echo@junsion.com.cn, or evelyn@junsion.com.cn.

Let Dongguan Junsion Precision Hardware Co., Ltd be your trusted partner for high-quality products. Contact us today to start your custom project!

_1755487551902.jpg)