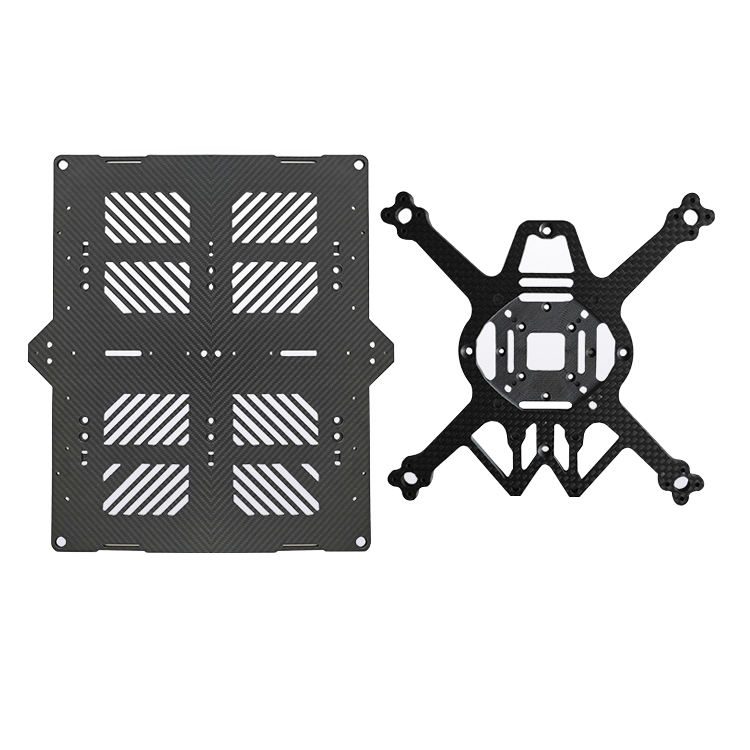

Precision Machining Drone Parts

Material: 45 steel,aluminum alloy,stainless steel, plastic,brass

Processing techniques: CNC, EDM, turning, five axis machining, stamping,hobbing, milling, grinding, drilling, tapping, reaming, pulling, cutting, etc

Finish:Polishing, painting, anodizing,sandblasting, plating ,blackening, electrophoresis, QPQ ,wire drawing

- Product Description

Precision Machining Drone Parts: Elevating UAV Performance with Junxion's Expertise

At Dongguan Junsion Precision Hardware Co., Ltd., we specialize in manufacturing high-quality precision machining drone parts. Our advanced CNC capabilities and commitment to excellence make us a trusted supplier for the UAV industry. With tolerances up to ±0.01mm, we deliver components that meet the exacting standards of commercial drone manufacturers, aerospace companies, and defense contractors.

Description

Our products are crafted to enhance the performance, reliability, and efficiency of unmanned aerial vehicles. We offer a wide range of components, including:

- Propeller hubs and adapters

- Motor mounts and housings

- Frame components and structural elements

- Gimbal parts for camera stabilization

- Landing gear components

- Battery compartment frames

- Payload attachment mechanisms

Each part is manufactured using state-of-the-art CNC machining centers, ensuring consistency and accuracy across production runs. We work with various materials, including:

- Aluminum alloys (6061, 7075)

- Titanium alloys

- Stainless steel (303, 304, 316)

- Carbon fiber-reinforced polymers

Our engineering team collaborates closely with clients to optimize designs for weight reduction, strength, and aerodynamics, crucial factors in drone performance.

Product Specifications

| Material | 1) Aluminum: AL 6061-T6, 6063, 7075-T etc. |

| 2) Stainless steel: 303,304,316L, 17-4(SUS630) etc. | |

| 3) Steel: 4140, Q235, Q345B,20#,45# etc. | |

| 4) Titanium: TA1,TA2/GR2, TA4/GR5, TC4, TC18 etc. | |

| 5) Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc. | |

| 5) Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc. | |

| Finish | Sandblasting, Anodize color, Blackenning, Zinc/Nickl Plating, Polish. |

| Power coating, Passivation PVD, Titanium Plating, Electrogalvanizing. | |

| Electroplating chromium, electrophoresis, QPQ(Quench-Polish-Quench). | |

| Electro Polishing,Chrome Plating, Knurl, Laser etch Logo, etc | |

| Main Equipment | STEP,STP,GIS,CAD,PDF,DWG,DXF etc or samples. |

| Tolerance | +/-0.01mm ~ +/-0.05mm |

| Surface roughness | Ra 0.1~3.2 |

| Inspection | Complete inspection lab with Micrometer, Optical Comparator, Caliper Vernier,CMM. |

| Depth Caliper Vernier, Universal Protractor, Clock Gauge, Internal Centigrade Gauge | |

| Capacity | CNC turning work range: φ0.5mm-φ150mm*300mm. |

| CNC milling work range: 510mm*1020mm*500mm. |

Surface Treatment

To enhance durability and functionality, we offer multiple surface treatment options for the products:

- Anodizing: Provides corrosion resistance and aesthetic appeal for aluminum components

- Hard coat anodizing: Offers superior wear resistance for high-stress parts

- Electroless nickel plating: Ensures uniform coating on complex geometries

- Powder coating: Delivers a durable, weather-resistant finish

- Passivation: Improves corrosion resistance of stainless steel parts

Our surface treatments comply with industry standards, including MIL-A-8625 and AMS 2700.

Drawing Guide

We accept various file formats for your precision machining drone parts:

- 3D CAD files (STEP, IGES, Solidworks)

- 2D drawings (DWG, DXF, PDF)

- Detailed technical specifications

Our engineering team reviews all drawings to ensure manufacturability and may suggest optimizations to improve performance or reduce costs.

Production Process

- Design Review: Our engineers analyze your drawings and provide feedback

- Material Selection: We source high-quality materials suited to your specifications

- CNC Programming: Our technicians create optimized toolpaths for efficient machining

- Precision Machining: Parts are manufactured on our advanced CNC equipment

- Quality Control: In-process and final inspections ensure adherence to tolerances

- Surface Treatment: Parts undergo specified finishing processes

- Final Inspection: Comprehensive checks before packaging and shipping

Quality Certification

Junxion maintains rigorous quality standards, including:

- ISO 9001:2015 certification

- AS9100D certification for aerospace components

- RoHS compliance for all materials

- 100% traceability through our quality management system

We use advanced measurement tools like CMM (Coordinate Measuring Machines) and optical comparators to verify dimensional accuracy.

Shipping and Delivery

We offer flexible shipping options to meet your production timelines:

- Express air freight for urgent orders

- Sea freight for cost-effective bulk shipments

- Door-to-door delivery through trusted logistics partners

Our packaging is designed to protect products during transit, ensuring they arrive in perfect condition.

Why Choose Us?

- Industry Expertise: Over a decade of experience in precision machining for UAV applications

- Custom Solutions: Tailored manufacturing processes to meet unique drone part requirements

- Competitive Pricing: Volume discounts and cost-effective production methods

- Quick Turnaround: Rapid prototyping and efficient production scheduling

- Quality Assurance: Rigorous testing and inspection protocols

- Technical Support: Ongoing assistance from our engineering team

- Global Reach: Serving clients across North America, Europe, and Asia

FAQ

Q: What is your minimum order quantity (MOQ) for the products?

A: Our MOQ varies depending on the complexity of the part. For standard components, we typically have an MOQ of 100 pieces. For custom designs, we can accommodate smaller quantities for prototyping.

Q: Can you provide samples before full production?

A: Yes, we offer prototyping services and can produce small batches for testing and approval before proceeding with larger orders.

Q: What is your typical lead time for the products?

A: Lead times vary based on complexity and quantity. Generally, we can deliver prototypes within 7-10 days and production orders within 2-4 weeks.

Q: Do you offer design assistance for drone parts?

A: Absolutely. Our engineering team can help optimize your designs for manufacturability, weight reduction, and improved performance.

Contact & Support

Ready to elevate your drone manufacturing with our precision machining expertise? Contact us today to discuss your project requirements or request a quote.

Email: Lock@junsion.com.cn, echo@junsion.com.cn, or evelyn@junsion.com.cn.

Trust Junxion for precision machining drone parts that propel your UAV designs to new heights of performance and reliability.