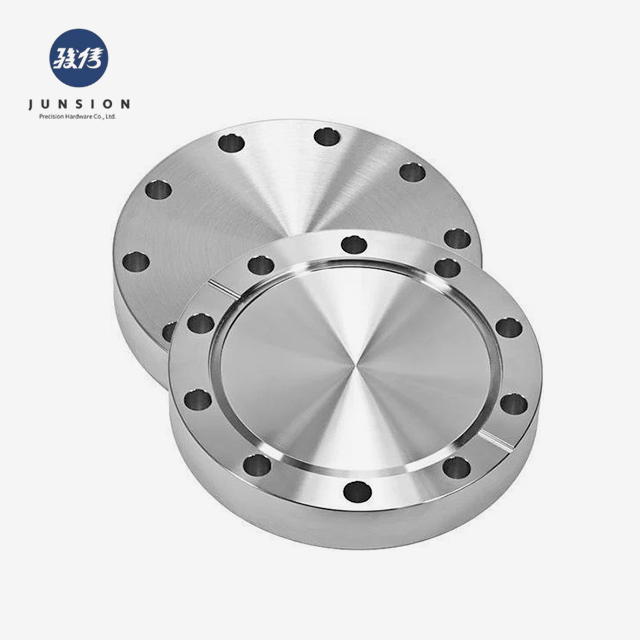

Mechanical Parts Flange

Material: 45 steel,aluminum alloy,stainless steel, plastic,brass

Processing techniques: CNC, EDM, turning, five axis machining, stamping,hobbing, milling, grinding, drilling, tapping, reaming, pulling, cutting, etc

Finish:Polishing, painting, anodizing,sandblasting, plating ,blackening, electrophoresis, QPQ ,wire drawing

- Product Description

Mechanical Parts Flange: Precision-Engineered Solutions for Industrial Applications

Dongguan Junsion Precision Hardware Co., Ltd. is a leading manufacturer and supplier of high-quality Mechanical Parts Flanges. Because we are dedicated to excellence and can do advanced precision machining, we are the first choice for businesses that need reliable, custom-engineered flange solutions. We always make products that are accurate, last a long time, and meet the strictest requirements, with tolerances of up to ±0.01mm.

Description

In many industrial settings, our products are necessary parts that connect pipes, valves, pumps, and other machinery. We have many kinds of flanges, including:

- Weld Neck Flanges

- Slip-On Flanges

- Socket Weld Flanges

- Lap Joint Flanges

- Threaded Flanges

- Blind Flanges

Each flange is precision-crafted using state-of-the-art CNC machinery, ensuring optimal performance and longevity in demanding environments.

| Material | 1) Aluminum: AL 6061-T6, 6063, 7075-T etc. |

| 2) Stainless steel: 303,304,316L, 17-4(SUS630) etc. | |

| 3) Steel: 4140, Q235, Q345B,20#,45# etc. | |

| 4) Titanium: TA1,TA2/GR2, TA4/GR5, TC4, TC18 etc. | |

| 5) Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc. | |

| 5) Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc. | |

| Finish | Sandblasting, Anodize color, Blackenning, Zinc/Nickl Plating, Polish. |

| Power coating, Passivation PVD, Titanium Plating, Electrogalvanizing. | |

| Electroplating chromium, electrophoresis, QPQ(Quench-Polish-Quench). | |

| Electro Polishing,Chrome Plating, Knurl, Laser etch Logo, etc | |

| Main Equipment | STEP,STP,GIS,CAD,PDF,DWG,DXF etc or samples. |

| Tolerance | +/-0.01mm ~ +/-0.05mm |

| Surface roughness | Ra 0.1~3.2 |

| Inspection | Complete inspection lab with Micrometer, Optical Comparator, Caliper Vernier,CMM. |

| Depth Caliper Vernier, Universal Protractor, Clock Gauge, Internal Centigrade Gauge | |

| Capacity | CNC turning work range: φ0.5mm-φ150mm*300mm. |

| CNC milling work range: 510mm*1020mm*500mm. |

Surface Treatment

To enhance durability and corrosion resistance, we provide multiple surface treatment options for our products:

- Anodizing (for aluminum flanges)

- Electroplating (zinc, nickel, chrome)

- Powder coating

- Sandblasting

- Polishing

- Passivation (for stainless steel)

Our expert team can recommend the most suitable surface treatment based on your specific application requirements.

Drawing Guide

We understand the importance of precision in flange design. Our engineering team works closely with clients to develop accurate technical drawings, considering factors such as:

- Flange type and dimensions

- Bolt hole pattern and size

- Pressure rating

- Material specifications

- Surface finish requirements

Our advanced CAD/CAM software ensures that every Mechanical Parts Flange meets exact specifications before production begins.

Production Process

Our streamlined production process guarantees consistent quality and efficiency:

- Material selection and inspection

- CNC machining (turning, milling, drilling)

- Heat treatment (if required)

- Surface treatment

- Quality control inspection

- Packaging and shipping

This comprehensive approach allows us to maintain strict quality standards while meeting tight production deadlines.

Quality Certification

Junxion is committed to maintaining the highest quality standards. Our products are manufactured in compliance with:

- ISO 9001:2015 Quality Management System

- ASME B16.5 Pipe Flanges and Flanged Fittings

- ASTM material standards

- RoHS compliance for environmental safety

Each flange undergoes rigorous testing and inspection to ensure it meets or exceeds industry standards.

Shipping and Delivery

We understand the importance of timely delivery in industrial operations. Our efficient logistics network enables us to offer:

- Sample delivery within 3 days

- Mass production orders within 7-15 days

- Flexible shipping options (air, sea, express)

- Secure packaging to prevent damage during transit

- Real-time order tracking

Our responsive customer service team keeps you informed throughout the shipping process, ensuring peace of mind.

Why Choose Us?

- Advanced Precision Machining: Our state-of-the-art equipment guarantees unparalleled accuracy.

- Customization Expertise: We offer tailored solutions to meet your specific flange requirements.

- Wide Material Selection: From stainless steel to exotic alloys, we have the right material for your application.

- Strict Quality Control: Our multi-stage inspection process ensures consistent, high-quality products.

- Fast Turnaround: We help you meet tight project deadlines without compromising on quality.

- Global Experience: With over 500 satisfied clients worldwide, we understand diverse industry needs.

- Competitive Pricing: Our efficient processes allow us to offer superior quality at competitive rates.

FAQ

Q: What materials do you use for the products?

A: We work with various metals, including stainless steel, carbon steel, aluminum, and specialty alloys.

Q: Can you produce custom flange designs?

A: Absolutely! We specialize in custom products based on your specifications or samples.

Q: What is your minimum order quantity?

A: We accommodate both small prototype orders and large-scale production runs. Contact us for specific MOQ details.

Q: Do you offer rush orders for urgent projects?

A: Yes, we can expedite orders for time-sensitive projects. Please inform us of your deadline when inquiring.

Q: How do you ensure product quality?

A: We implement strict quality control measures throughout the production process, including IQC, IPQC, and OQC inspections.

Contact & Support

Ready to elevate your industrial operations with precision-engineered Mechanical Parts Flanges? Contact our expert team today:

Email: Lock@junsion.com.cn, echo@junsion.com.cn, or evelyn@junsion.com.cn.

Let Junxion be your trusted partner in delivering high-quality, custom flange solutions that drive your business forward.

_1755495307676.jpg)

_1755495308160.jpg)

_1755495308202.jpg)

_1755487551902.jpg)

_1755488086603.jpg)