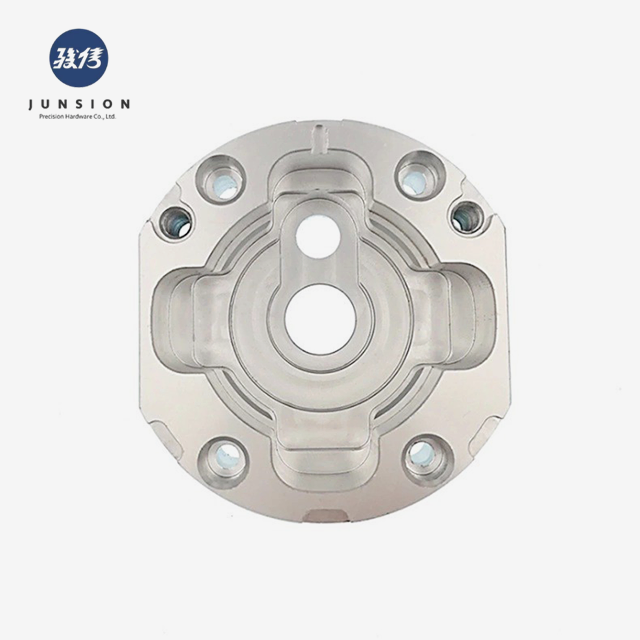

5 Axis CNC Machine Parts

Material: 45 steel,aluminum alloy,stainless steel, plastic,brass

Processing techniques: CNC, EDM, turning, five axis machining, stamping,hobbing, milling, grinding, drilling, tapping, reaming, pulling, cutting, etc

Finish:Polishing, painting, anodizing,sandblasting, plating ,blackening, electrophoresis, QPQ ,wire drawing

- Product Description

5 Axis CNC Machine Parts: Precision Engineering for Complex Components

Welcome to Dongguan Junsion Precision Hardware Co., Ltd., your trusted partner for high-quality 5 Axis CNC Machine Parts. As a top manufacturer and seller, we focus on sending precision-engineered parts to fields that need the highest level of accuracy and complexity. With our advanced 5-axis CNC machining, we can make complicated parts with unmatched accuracy. This makes us the best choice for aerospace, automobile, medical, and industrial needs.

Advantages

Junsion is proud of its cutting edge 5-axis CNC machining tools, which can make parts with tolerances of up to ±0.01mm. Because we are experts in multi-axis machining, we can easily handle even the most complicated geometries and give you parts that meet and go beyond your standards. We offer one-stop custom solutions that help you from development to mass production and give you personalized help at every step of the way.

Description

Our products are the epitome of precision engineering. These components are crafted using cutting-edge technology that allows for simultaneous movement across five axes, enabling the creation of complex shapes and contours with exceptional accuracy. Whether you need aerospace components, medical implants, or custom automotive parts, our 5-axis machining capabilities ensure:

- Ultra-high precision with tolerances as tight as ±0.001mm

- Complex geometries and undercuts that are impossible with traditional machining

- Reduced setup times and increased productivity

- Consistent quality across large production runs

- Capability to work with a wide range of materials, including titanium, Inconel, and other exotic al

| Material | 1) Aluminum: AL 6061-T6, 6063, 7075-T etc. |

| 2) Stainless steel: 303,304,316L, 17-4(SUS630) etc. | |

| 3) Steel: 4140, Q235, Q345B,20#,45# etc. | |

| 4) Titanium: TA1,TA2/GR2, TA4/GR5, TC4, TC18 etc. | |

| 5) Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc. | |

| 5) Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc. | |

| Finish | Sandblasting, Anodize color, Blackenning, Zinc/Nickl Plating, Polish. |

| Power coating, Passivation PVD, Titanium Plating, Electrogalvanizing. | |

| Electroplating chromium, electrophoresis, QPQ(Quench-Polish-Quench). | |

| Electro Polishing,Chrome Plating, Knurl, Laser etch Logo, etc | |

| Main Equipment | STEP,STP,GIS,CAD,PDF,DWG,DXF etc or samples. |

| Tolerance | +/-0.01mm ~ +/-0.05mm |

| Surface roughness | Ra 0.1~3.2 |

| Inspection | Complete inspection lab with Micrometer, Optical Comparator, Caliper Vernier,CMM. |

| Depth Caliper Vernier, Universal Protractor, Clock Gauge, Internal Centigrade Gauge | |

| Capacity | CNC turning work range: φ0.5mm-φ150mm*300mm. |

| CNC milling work range: 510mm*1020mm*500mm. |

Surface Treatment

To enhance the performance and longevity of your products, we offer a variety of surface treatments:

- Anodizing: Improves corrosion resistance and creates decorative finishes

- Electroplating: Enhances conductivity and wear resistance

- Sandblasting: Provides a uniform matte finish

- Brushing: Creates a sleek, directional grain appearance

All our surface treatments are RoHS-compliant, ensuring both quality and environmental safety.

Drawing Guide

We understand the importance of precise communication when it comes to custom parts. Our engineering team is ready to work with your drawings or samples to bring your vision to life. We accept:

- 2D drawings in DWG, DXF, or PDF formats

- 3D models in STEP, IGS, or X_T formats

- Physical samples for reverse engineering

Our experts are available to provide guidance on design optimization for manufacturability, ensuring your parts are not only precise but also cost-effective to produce.

Production Process

Our rigorous production process for 5 Axis CNC Machine Parts includes:

- Design Review and Optimization

- Material Selection and Procurement

- CNC Programming and Simulation

- 5-Axis CNC Machining

- In-Process Quality Control (IPQC)

- Surface Treatment (if required)

- Final Quality Inspection (OQC)

- Packaging and Shipping

Each step is carefully monitored to ensure the highest quality standards are maintained throughout the production cycle.

Quality Certification

Quality is at the heart of everything we do. Our products production is backed by:

- ISO 9001:2015 Certification

- AS9100D Certification (for aerospace components)

- ISO 13485 Certification (for medical devices)

- Regular third-party audits and inspections

We use advanced testing equipment such as CMM (Coordinate Measuring Machines), optical comparators, and material analysis tools to ensure every part meets your specifications.

Shipping and Delivery

We understand the importance of timely delivery in today's fast-paced manufacturing environment. Our efficient production scheduling and reliable logistics network allow us to offer:

- Sample delivery within 3 days

- Mass production orders within 7-15 days

- Flexible shipping options including air freight, sea freight, and express courier services

- Full tracking and insurance for peace of mind

Why Choose Us?

- Expertise in Complex Geometries: Our 5-axis CNC machining centers can handle the most intricate designs.

- Material Versatility: We work with a wide range of metals, including stainless steel, aluminum, titanium, and exotic alloys.

- Cost-Effective Solutions: Our efficient processes and volume discounts help you maximize your budget.

- Responsive Customer Service: Our team is always ready to address your questions and concerns.

- Global Reach: With over 500 satisfied clients worldwide, we have the experience to meet international standards and requirements.

FAQ

Q: What is the minimum order quantity for the products?

A: We offer flexible MOQs based on part complexity and material. Contact us for a custom quote.

Q: Can you provide prototypes before mass production?

A: Yes, we specialize in rapid prototyping to ensure your design is perfect before scaling up.

Q: What industries do you typically serve with your products?

A: We serve aerospace, automotive, medical, energy, and industrial sectors, among others.

Contact & Support

Ready to elevate your manufacturing with precision 5 Axis CNC Machine Parts? Contact our expert team today to discuss your project needs and receive a customized quote.

Email: Lock@junsion.com.cn, echo@junsion.com.cn, or evelyn@junsion.com.cn.

Trust Dongguan Junsion Precision Hardware Co., Ltd. for all your complex machining needs. Let's build something extraordinary together!

_1755487551902.jpg)

_1755488086603.jpg)