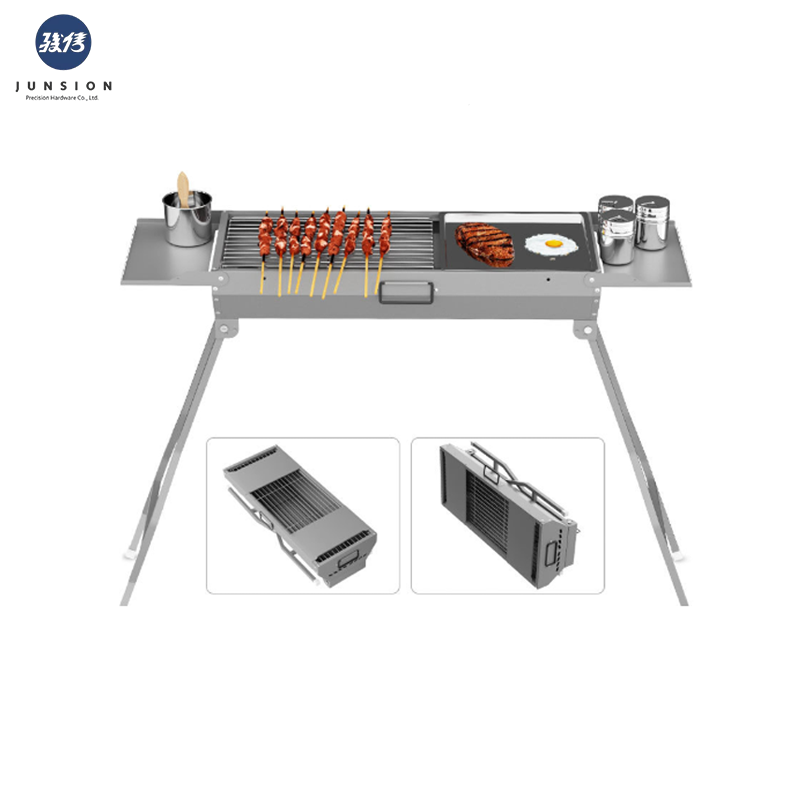

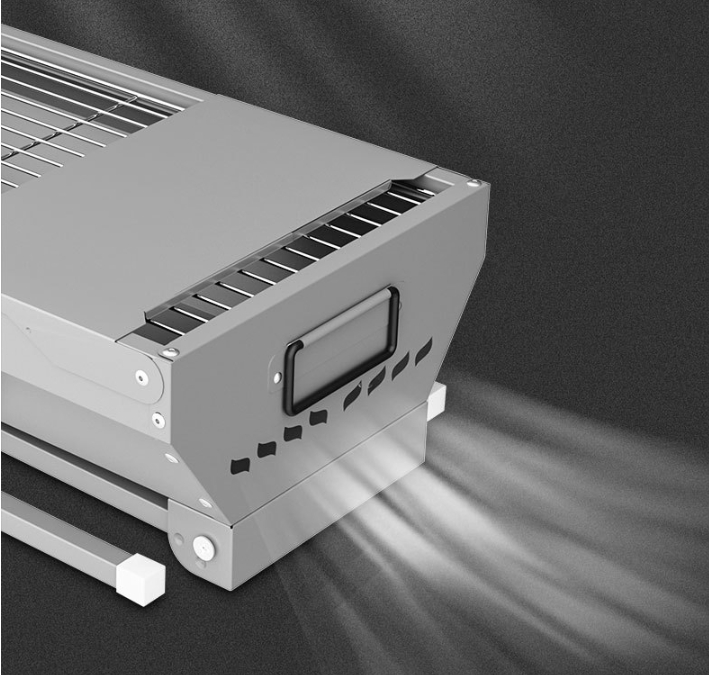

Barbecue Grill Metal Parts

Material: 45 steel,aluminum alloy,stainless steel, plastic,brass

Processing techniques: CNC, EDM, turning, five axis machining, stamping,hobbing, milling, grinding, drilling, tapping, reaming, pulling, cutting, etc

Finish:Polishing, painting, anodizing,sandblasting, plating ,blackening, electrophoresis, QPQ ,wire drawing

- Product Description

Barbecue Grill Metal Parts: Premium Quality Components for Your Grill Manufacturing Needs

Welcome to Dongguan Junsion Precision Hardware Co., Ltd., your trusted manufacturer and supplier of high-quality Barbecue Grill Metal Parts. Because we are dedicated to excellence and use advanced precision machining, we can make parts that are long-lasting and resistant to heat that meet the high standards of the outdoor cooking business. Our products are made to make your grills work better and last longer, so you can be sure that you'll be happy with them.

Description

At Junsion, we specialize in crafting a wide range of essential products to meet your specific manufacturing needs:

- Grill Grates: Precision-engineered stainless steel or cast iron grates that provide even heat distribution and durability.

- Burner Assemblies: High-performance burners designed for consistent heat output and longevity.

- Heat Shields and Flame Tamers: Protective components that enhance heat distribution and prevent flare-ups.

- Control Knobs and Valves: Ergonomic, temperature-resistant parts for precise heat control.

- Grill Housings and Lids: Sturdy, corrosion-resistant exteriors that withstand outdoor elements.

- Warming Racks: Additional cooking surfaces for versatile food preparation.

- Drip Pans and Grease Management Systems: Efficient solutions for easy cleaning and maintenance.

High-quality materials like 304 and 316 stainless steel, cast iron, and aluminum alloys are used to make our goods. We make sure that every part meets strict quality standards so that it can be used outside and heated many times.

| Material | 1) Aluminum: AL 6061-T6, 6063, 7075-T etc. |

| 2) Stainless steel: 303,304,316L, 17-4(SUS630) etc. | |

| 3) Steel: 4140, Q235, Q345B,20#,45# etc. | |

| 4) Titanium: TA1,TA2/GR2, TA4/GR5, TC4, TC18 etc. | |

| 5) Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc. | |

| 5) Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc. | |

| Finish | Sandblasting, Anodize color, Blackenning, Zinc/Nickl Plating, Polish. |

| Power coating, Passivation PVD, Titanium Plating, Electrogalvanizing. | |

| Electroplating chromium, electrophoresis, QPQ(Quench-Polish-Quench). | |

| Electro Polishing,Chrome Plating, Knurl, Laser etch Logo, etc | |

| Main Equipment | STEP,STP,GIS,CAD,PDF,DWG,DXF etc or samples. |

| Tolerance | +/-0.01mm ~ +/-0.05mm |

| Surface roughness | Ra 0.1~3.2 |

| Inspection | Complete inspection lab with Micrometer, Optical Comparator, Caliper Vernier,CMM. |

| Depth Caliper Vernier, Universal Protractor, Clock Gauge, Internal Centigrade Gauge | |

| Capacity | CNC turning work range: φ0.5mm-φ150mm*300mm. |

| CNC milling work range: 510mm*1020mm*500mm. |

Surface Treatment

To enhance the performance and aesthetics of your products, we offer various surface treatment options:

- Electropolishing: Improves corrosion resistance and creates a smooth, easy-to-clean surface.

- Powder Coating: Provides a durable, attractive finish in a range of colors.

- Anodizing: Enhances hardness and wear resistance for aluminum parts.

- Heat-resistant Coatings: Protects components exposed to high temperatures.

- Non-stick Treatments: Applied to cooking surfaces for improved food release and easy cleaning.

Drawing Guide

Our engineering team works closely with your designers to ensure precise manufacturing of your products:

- We accept 2D and 3D CAD files in various formats (e.g., .dwg, .dxf, .step).

- Detailed specifications for materials, tolerances, and surface finishes are crucial.

- We offer design optimization suggestions to improve manufacturability and reduce costs.

- Prototyping services are available for testing and refinement before mass production.

Production Process

Our state-of-the-art facility employs a rigorous production process for Barbecue Grill Metal Parts:

- Material Sourcing: We use only high-quality, RoHS-compliant metals.

- CNC Machining: Precision cutting, drilling, and shaping of components.

- Stamping and Forming: For high-volume sheet metal parts.

- Welding and Assembly: Expert joining of multiple components.

- Surface Treatment: Application of chosen finishes and coatings.

- Quality Control: Rigorous testing at each production stage.

- Packaging and Shipping: Secure packaging to prevent damage during transit.

Quality Certification

Our commitment to quality is reflected in our certifications:

- ISO 9001:2015 Quality Management System

- ISO 14001:2015 Environmental Management System

- ASTM A240 Compliance for Stainless Steel

- RoHS and REACH Compliance for Environmental Safety

Shipping and Delivery

We understand the importance of timely delivery in your supply chain:

- Flexible shipping options: air, sea, or express courier services.

- Careful packaging to protect products during transit.

- Real-time order tracking and dedicated logistics support.

- Quick turnaround: 3-day sample delivery, 7-15 days for mass production orders.

Why Choose Us?

- Expertise: Over a decade of experience in metal fabrication for the BBQ industry.

- Quality: Stringent quality control measures ensure consistent, high-quality parts.

- Customization: Tailored solutions to meet your specific design requirements.

- Cost-Effectiveness: Competitive pricing and bulk order discounts available.

- Reliability: On-time delivery and excellent after-sales support.

FAQ

Q: What is your minimum order quantity (MOQ) for the products?

A: Our MOQ varies depending on the complexity of the part. We offer flexible options for both small and large orders.

Q: Can you provide samples before mass production?

A: Yes, we offer prototyping and sample production services to ensure your satisfaction before full-scale manufacturing.

Q: What materials do you recommend for grill grates?

A: We often recommend 304 stainless steel or cast iron for grill grates due to their durability and heat resistance.

Q: How do you ensure the quality of your products?

A: We employ a comprehensive quality control system, including material inspection, in-process checks, and final product testing.

Contact & Support

Ready to elevate your barbecue grill production with our premium Barbecue Grill Metal Parts? Contact our team today for expert advice, quotes, and support:

Email: Lock@junsion.com.cn, echo@junsion.com.cn, or evelyn@junsion.com.cn.

Partner with Junsion for reliable, high-quality products that will set your products apart in the competitive outdoor cooking market.

_1755670903756.jpg)

_1755501959362.jpg)

_1755502686263.jpg)

_1755502812953.jpg)