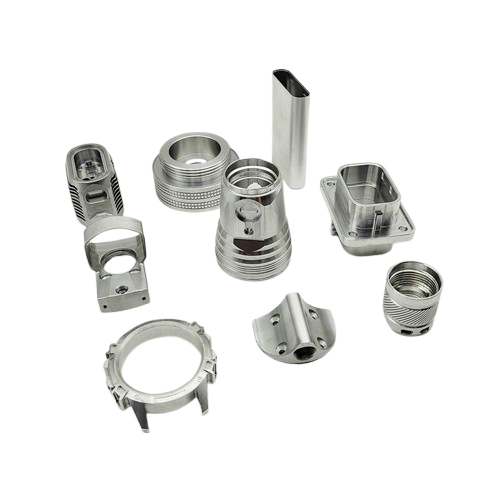

Pump Parts

Material: 45 steel,aluminum alloy,stainless steel, plastic,brass

Processing techniques: CNC, EDM, turning, five axis machining, stamping,hobbing, milling, grinding, drilling, tapping, reaming, pulling, cutting, etc

Finish:Polishing, painting, anodizing,sandblasting, plating ,blackening, electrophoresis, QPQ ,wire drawing

- Product Description

Pump Parts: Precision-Engineered Solutions for Industrial Excellence

At Dongguan Junsion Precision Hardware Co;Ltd, we specialize in manufacturing high-quality Pump Parts for various industrial applications. Our advanced precision machining capabilities and commitment to quality ensure that our products meet the most demanding specifications. With a wide range of materials and customization options, we deliver reliable solutions for your pump system needs.

Description

Our comprehensive range of the products includes:

- Impellers

- Casings

- Shafts

- Seals and Gaskets

- Bearings

- Wear Rings

- Volutes

- Diffusers

Each component is engineered to precise tolerances, ensuring optimal performance and longevity in your pump systems. We use advanced CNC machining technology to produce parts with tolerances up to ±0.01mm, guaranteeing consistent accuracy and reliability.

| Material | 1) Aluminum: AL 6061-T6, 6063, 7075-T etc. |

| 2) Stainless steel: 303,304,316L, 17-4(SUS630) etc. | |

| 3) Steel: 4140, Q235, Q345B,20#,45# etc. | |

| 4) Titanium: TA1,TA2/GR2, TA4/GR5, TC4, TC18 etc. | |

| 5) Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc. | |

| 5) Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc. | |

| Finish | Sandblasting, Anodize color, Blackenning, Zinc/Nickl Plating, Polish. |

| Power coating, Passivation PVD, Titanium Plating, Electrogalvanizing. | |

| Electroplating chromium, electrophoresis, QPQ(Quench-Polish-Quench). | |

| Electro Polishing,Chrome Plating, Knurl, Laser etch Logo, etc | |

| Main Equipment | STEP,STP,GIS,CAD,PDF,DWG,DXF etc or samples. |

| Tolerance | +/-0.01mm ~ +/-0.05mm |

| Surface roughness | Ra 0.1~3.2 |

| Inspection | Complete inspection lab with Micrometer, Optical Comparator, Caliper Vernier,CMM. |

| Depth Caliper Vernier, Universal Protractor, Clock Gauge, Internal Centigrade Gauge | |

| Capacity | CNC turning work range: φ0.5mm-φ150mm*300mm. |

| CNC milling work range: 510mm*1020mm*500mm. |

Surface Treatment

To enhance durability and performance, we offer various surface treatments for our products:

- Anodizing (for aluminum parts)

- Electroplating

- Sandblasting

- Brushing

- Powder coating

These treatments improve corrosion resistance, wear resistance, and overall part longevity, crucial for pump components operating in challenging environments.

Drawing Guide

We accept various formats for your products designs:

- 2D CAD drawings (DWG, DXF)

- 3D models (STEP, IGS)

- Detailed sketches with measurements

Our engineering team can assist in optimizing your designs for manufacturability and performance. We also offer reverse engineering services if you need to replicate or improve existing parts.

Production Process

Our streamlined production process ensures high-quality Pump Parts:

- Design review and optimization

- Material selection and sourcing

- CNC machining or turning

- In-process quality control (IPQC)

- Surface treatment (if required)

- Final quality inspection (OQC)

- Packaging and shipping

This process allows us to deliver samples within 3 days and complete mass production orders in 7-15 days, helping you minimize downtime and meet tight schedules.

Quality Certification

We maintain strict quality control measures throughout our production process:

- ISO 9001:2015 certified quality management system

- RoHS compliance for all materials

- Advanced testing equipment (2.5D projectors, hardness testers, salt spray machines)

- 100% inspection of critical dimensions and features

These certifications and processes ensure that every product meets or exceeds industry standards and your specific requirements.

Shipping and Delivery

We offer flexible shipping options to meet your needs:

- Express delivery for urgent orders

- Sea freight for large volume shipments

- Air freight for balanced speed and cost

Our reliable logistics network ensures timely delivery to destinations worldwide, including Europe, North America, Southeast Asia, and Japan.

Why Choose Us?

- Advanced precision machining capabilities

- Customizable solutions for your specific needs

- Wide range of materials and surface treatments

- Fast turnaround times

- Strict quality control measures

- Extensive industry experience

- Global reach and reliable shipping

Our customer-centric approach and commitment to quality make us your ideal partner for long-term products manufacturing cooperation.

FAQ

Q: What is the minimum order quantity (MOQ) for the products?

A: Our MOQ varies depending on the complexity and size of the part. We offer flexible options and can discuss your specific needs.

Q: Can you provide custom materials for the products?

A: Yes, we work with a variety of metals including stainless steel, aluminum, copper, and titanium. We can recommend the best material based on your application.

Q: Do you offer design assistance for the products?

A: Absolutely. Our engineering team can help optimize your designs for manufacturability and performance.

Q: What quality control measures do you have in place?

A: We have a comprehensive quality control system that includes incoming material inspection, in-process control, and final inspection using advanced testing equipment.

Contact & Support

Ready to discuss your Pump Parts needs? Our team is here to help!

- Email: Lock@junsion.com.cn, echo@junsion.com.cn, or evelyn@junsion.com.cn.

Contact us today for expert advice, quotations, or to start your custom products project. At Dongguan Junsion Precision Hardware Co;Ltd, we're committed to delivering precision-engineered solutions that drive your success.

_1755502598012.jpg)

_1755502598106.jpg)

_1755501959362.jpg)