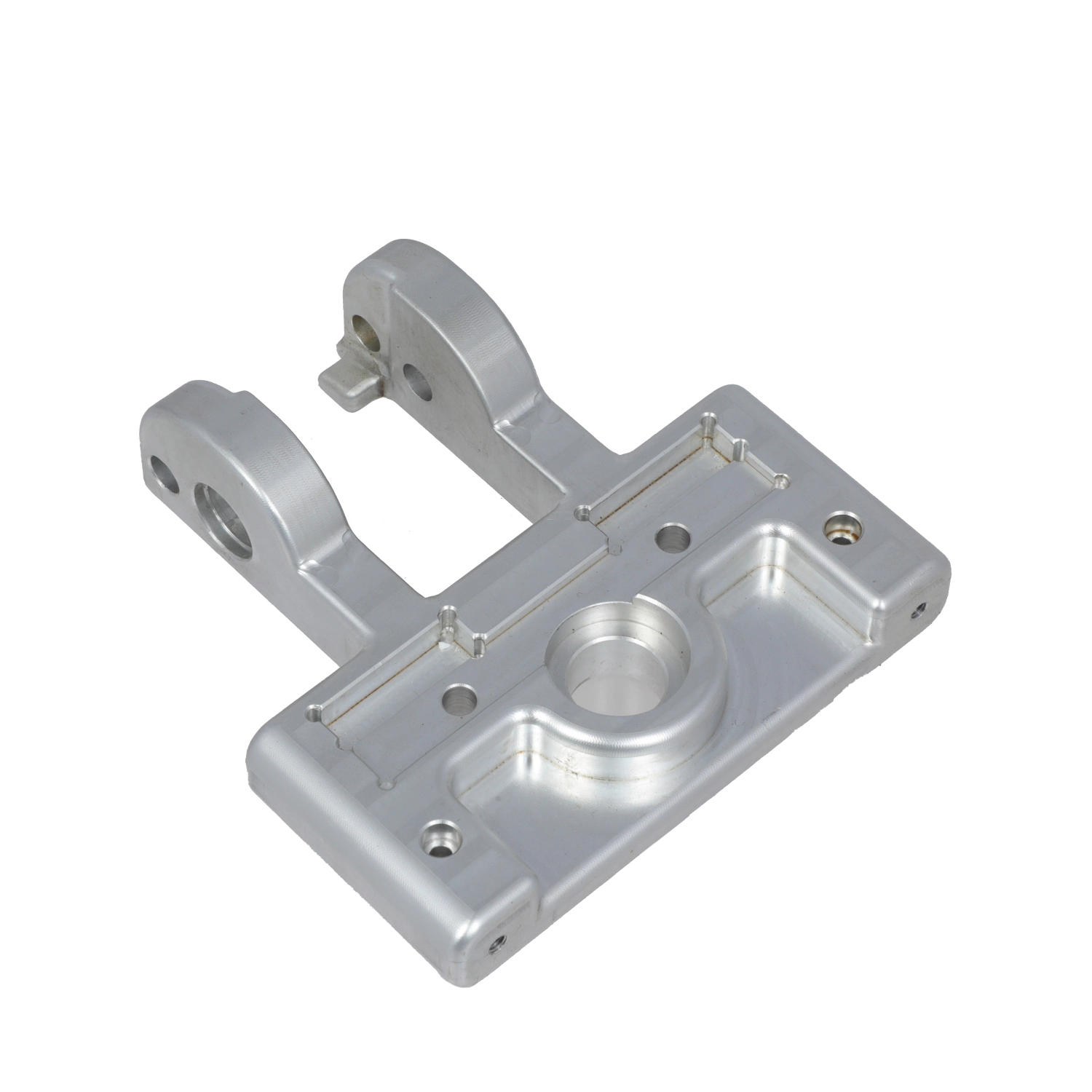

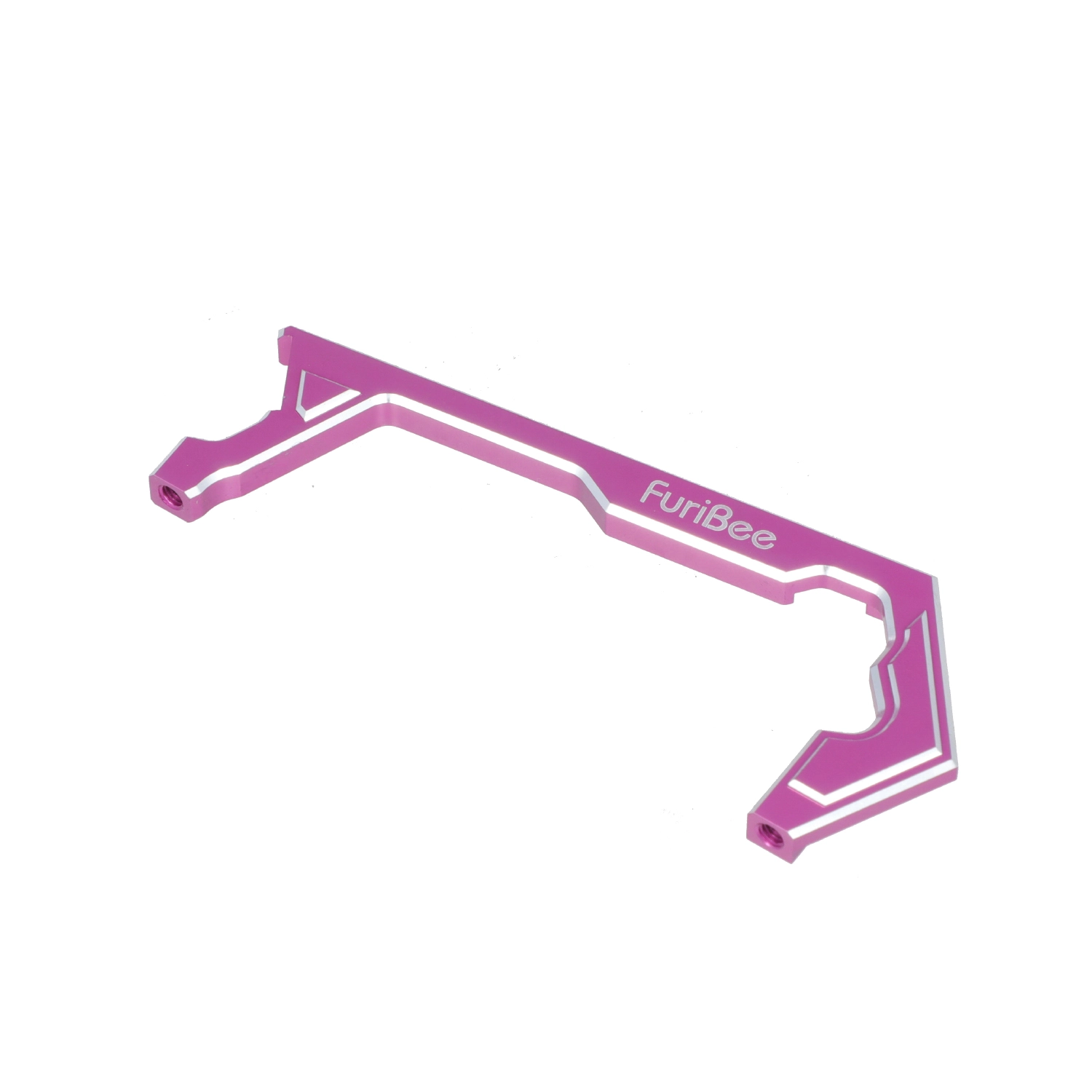

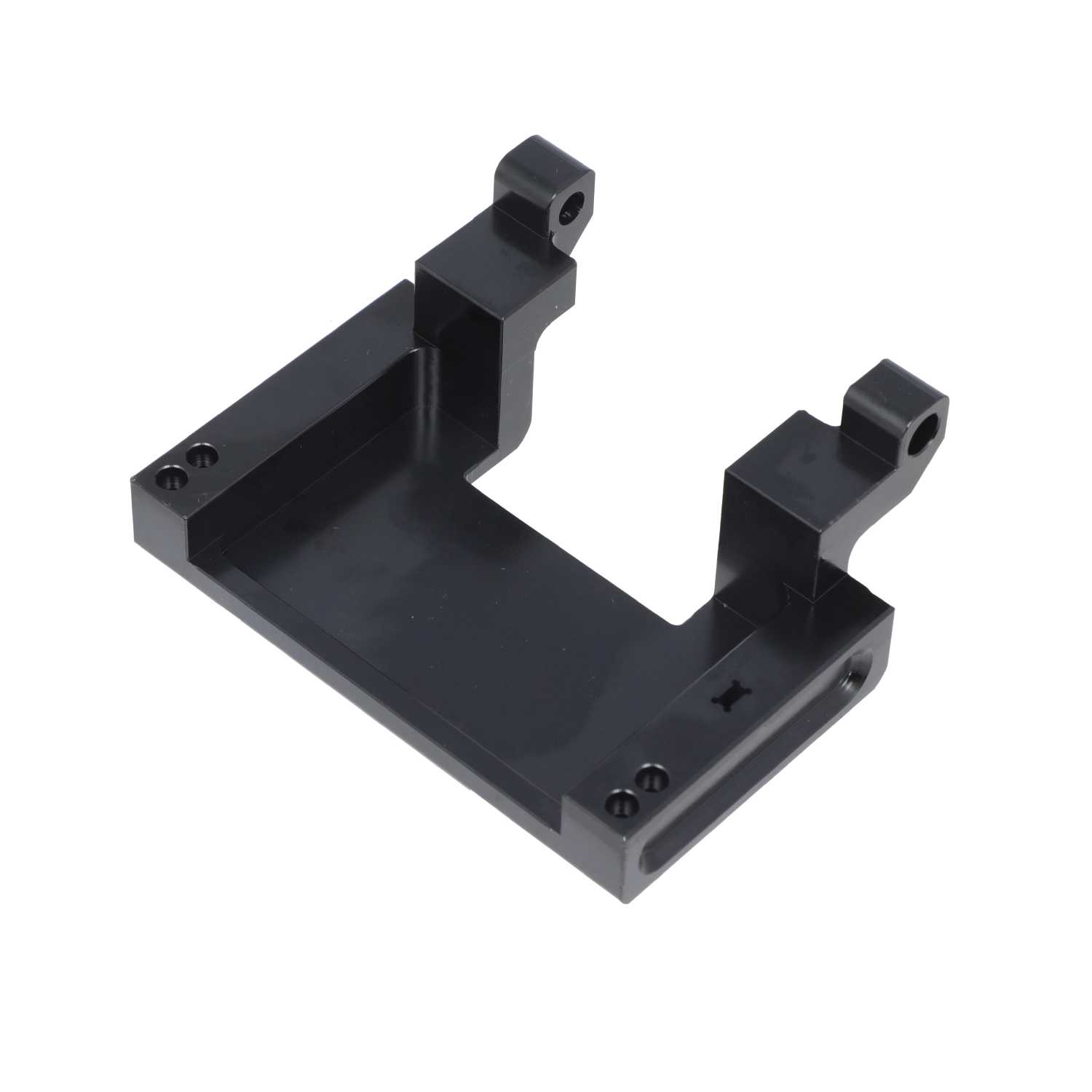

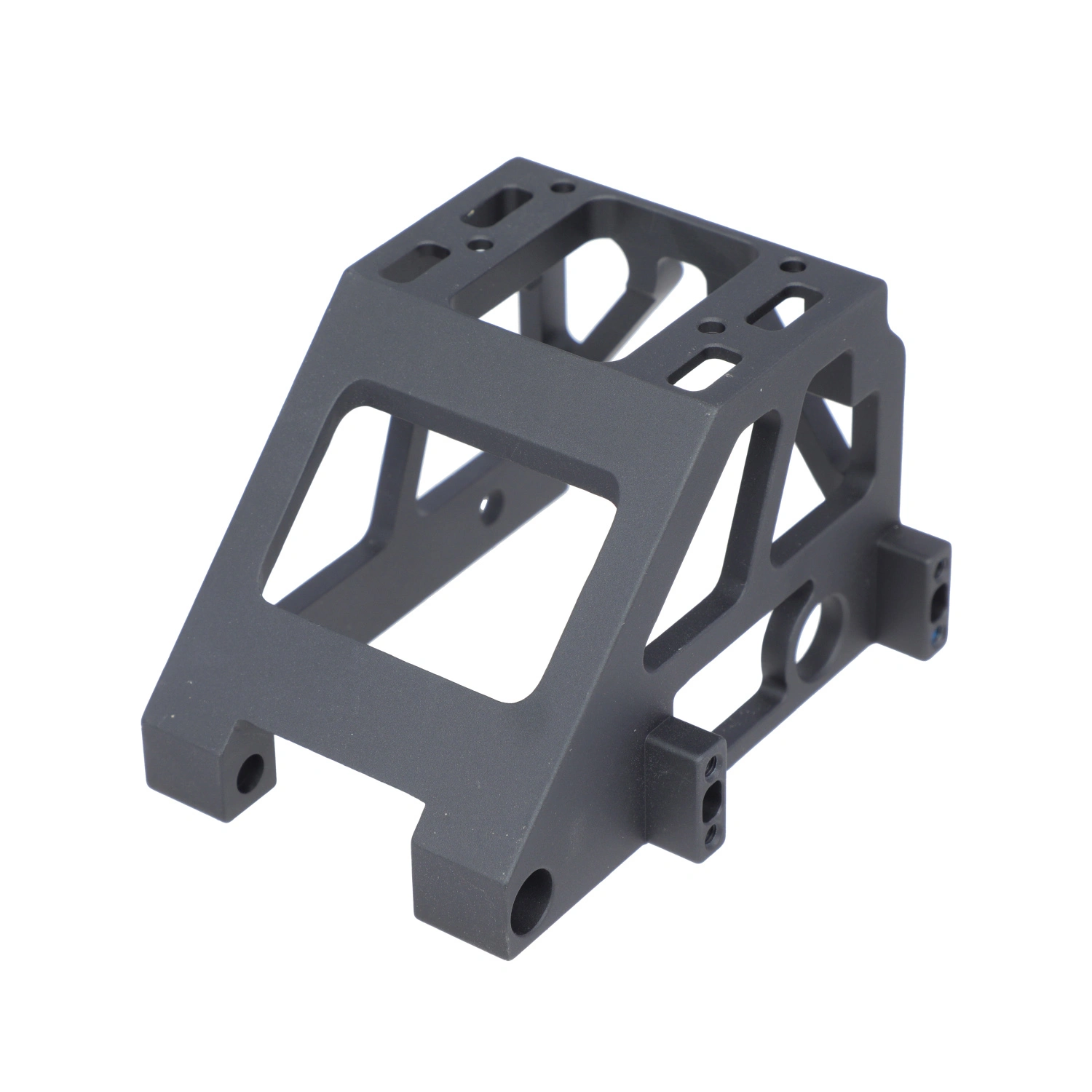

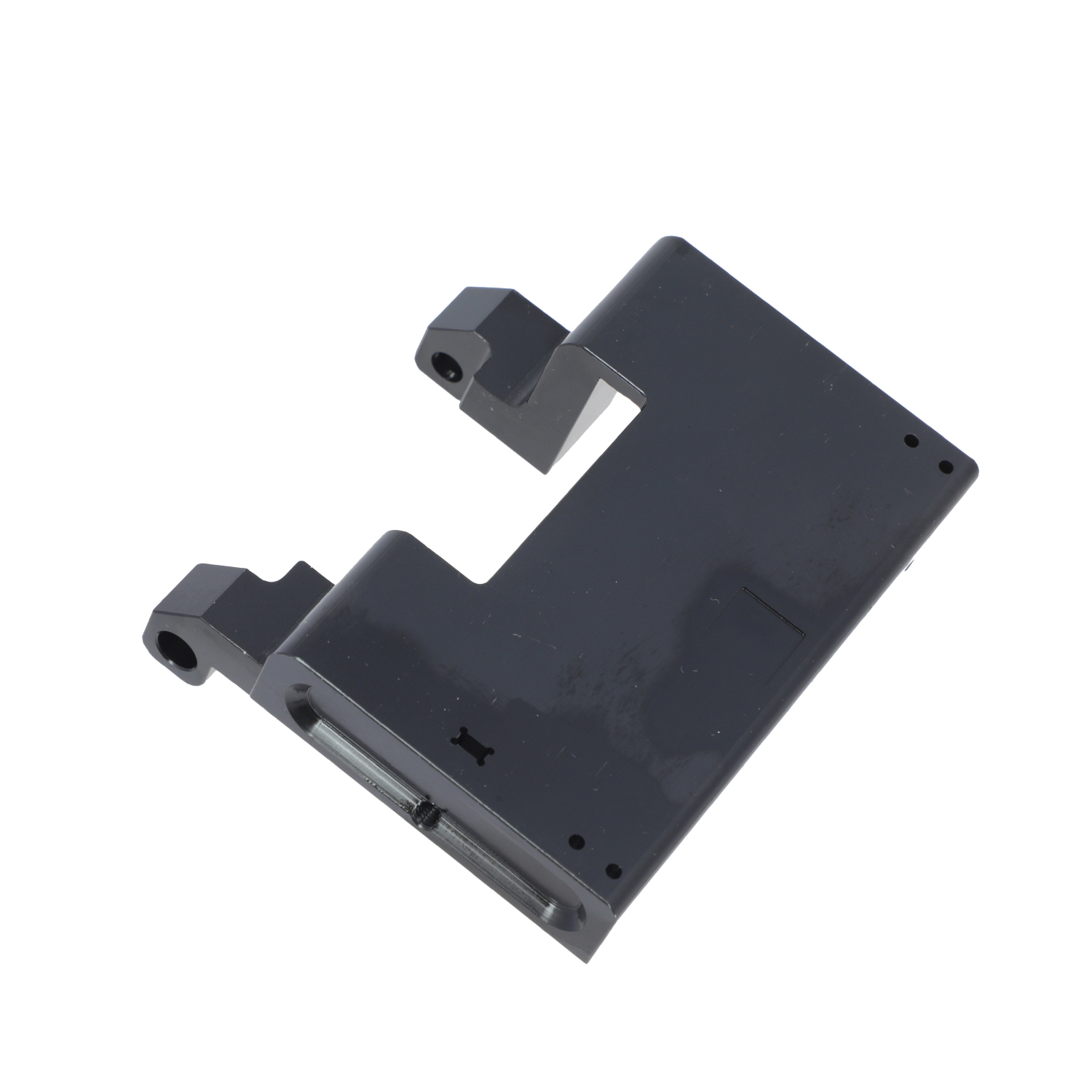

Custom Car Roof Rack

Material: 45 steel,aluminum alloy,stainless steel, plastic,brass

Processing techniques: CNC, EDM, turning, five axis machining, stamping,hobbing, milling, grinding, drilling, tapping, reaming, pulling, cutting, etc

Finish:Polishing, painting, anodizing,sandblasting, plating ,blackening, electrophoresis, QPQ ,wire drawing

- Product Description

Custom Car Roof Racks: Precision-Engineered for Your Vehicle

At Dongguan Junsion Precision Hardware Co., Ltd., we specialize in manufacturing top-quality Custom Car Roof Racks tailored to your specific needs. Our advanced precision machining and one-stop custom solutions ensure that every roof rack we produce meets the highest standards of durability, functionality, and style. With our wide material selection and strict quality control, we deliver products that stand the test of time and enhance your vehicle's versatility.

Description

Our products are designed to provide secure and convenient cargo transportation for various vehicle types. We offer:

- Vehicle-specific designs for perfect fitment

- Aerodynamic profiles to minimize wind noise and fuel consumption

- High load capacity to accommodate diverse cargo needs

- Modular systems for easy installation and removal

- Corrosion-resistant materials for long-lasting performance

Whether you're an automotive manufacturer, parts distributor, or fleet manager, our custom racks are engineered to meet your exact specifications and exceed industry standards.

| Material | 1) Aluminum: AL 6061-T6, 6063, 7075-T etc. |

| 2) Stainless steel: 303,304,316L, 17-4(SUS630) etc. | |

| 3) Steel: 4140, Q235, Q345B,20#,45# etc. | |

| 4) Titanium: TA1,TA2/GR2, TA4/GR5, TC4, TC18 etc. | |

| 5) Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc. | |

| 5) Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc. | |

| Finish | Sandblasting, Anodize color, Blackenning, Zinc/Nickl Plating, Polish. |

| Power coating, Passivation PVD, Titanium Plating, Electrogalvanizing. | |

| Electroplating chromium, electrophoresis, QPQ(Quench-Polish-Quench). | |

| Electro Polishing,Chrome Plating, Knurl, Laser etch Logo, etc | |

| Main Equipment | STEP,STP,GIS,CAD,PDF,DWG,DXF etc or samples. |

| Tolerance | +/-0.01mm ~ +/-0.05mm |

| Surface roughness | Ra 0.1~3.2 |

| Inspection | Complete inspection lab with Micrometer, Optical Comparator, Caliper Vernier,CMM. |

| Depth Caliper Vernier, Universal Protractor, Clock Gauge, Internal Centigrade Gauge | |

| Capacity | CNC turning work range: φ0.5mm-φ150mm*300mm. |

| CNC milling work range: 510mm*1020mm*500mm. |

Surface Treatment

To ensure optimal performance and aesthetics, we offer various surface treatments for our products:

- Anodizing for enhanced corrosion resistance and color options

- Powder coating for durability and custom color matching

- Brushed or polished finishes for a sleek, premium look

- Anti-slip coatings for improved grip and safety

Our expertise in surface finishing allows us to tailor the appearance and functionality of your roof racks to your brand's unique requirements.

Drawing Guide

We understand the importance of precision in custom manufacturing. Our team of skilled engineers works closely with you to:

- Review your initial designs or concepts

- Provide technical feedback and optimization suggestions

- Create detailed 3D models and 2D drawings

- Ensure all specifications meet safety and regulatory standards

Our collaborative approach ensures that your Custom Car Roof Racks are perfectly tailored to your needs from the very beginning.

Production Process

Our state-of-the-art facility employs a rigorous production process:

- Material selection and quality inspection

- CNC machining of components with tolerances up to ±0.01mm

- Assembly and fitment checks

- Surface treatment application

- Quality control inspections at each stage

- Final assembly and packaging

This meticulous process guarantees consistent quality and reliability for every custom roof rack we produce.

Quality Certification

We take pride in our commitment to quality. Our products are:

- ISO 9001:2015 certified for quality management

- Compliant with automotive industry standards (e.g., IATF 16949)

- Tested for durability, load capacity, and weather resistance

- RoHS compliant, ensuring environmental safety

Our certifications demonstrate our dedication to delivering products that meet the highest international standards.

Shipping and Delivery

We understand the importance of timely delivery in the automotive industry. Our efficient production scheduling and reliable logistics network ensure:

- Sample delivery within 3 days

- Mass production orders fulfilled in 7-15 days

- Flexible shipping options to meet your inventory needs

- Secure packaging to prevent damage during transit

Our fast turnaround times help you stay competitive and responsive to market demands.

Why Choose Us?

- Industry Expertise: With over 500 satisfied clients worldwide, we have the experience to meet diverse automotive needs.

- Customization Capabilities: Our advanced machinery and skilled team can bring your unique designs to life.

- Quality Assurance: Our strict quality control system ensures every product meets or exceeds expectations.

- Cost-Efficiency: Our bulk production capabilities allow for competitive pricing without compromising quality.

- Responsive Service: Our customer-centric approach means we're always ready to address your concerns and adapt to your needs.

FAQ

Q: What is the minimum order quantity (MOQ) for custom roof racks?

A: Our MOQ varies based on the complexity of the design. Contact us for a personalized quote.

Q: Can you provide prototypes before mass production?

A: Yes, we offer prototyping services to ensure the final product meets your exact specifications.

Q: What materials do you use for your roof racks?

A: We primarily use aluminum and stainless steel, but can work with other metals based on your requirements.

Q: How do you ensure the quality of your products?

A: We employ a comprehensive quality control system, including IQC, IPQC, and OQC, using advanced testing equipment.

Contact & Support

Ready to elevate your vehicle accessories offering with our Custom Car Roof Racks? Contact us today to discuss your project:

Email: Lock@junsion.com.cn, echo@junsion.com.cn, or evelyn@junsion.com.cn.

Let Dongguan Junsion Precision Hardware Co., Ltd. be your trusted partner in custom automotive solutions. We're committed to delivering precision-engineered roof racks that meet your exact needs and exceed your expectations.

_1763437634980.jpg)

_1755499208108.jpg)