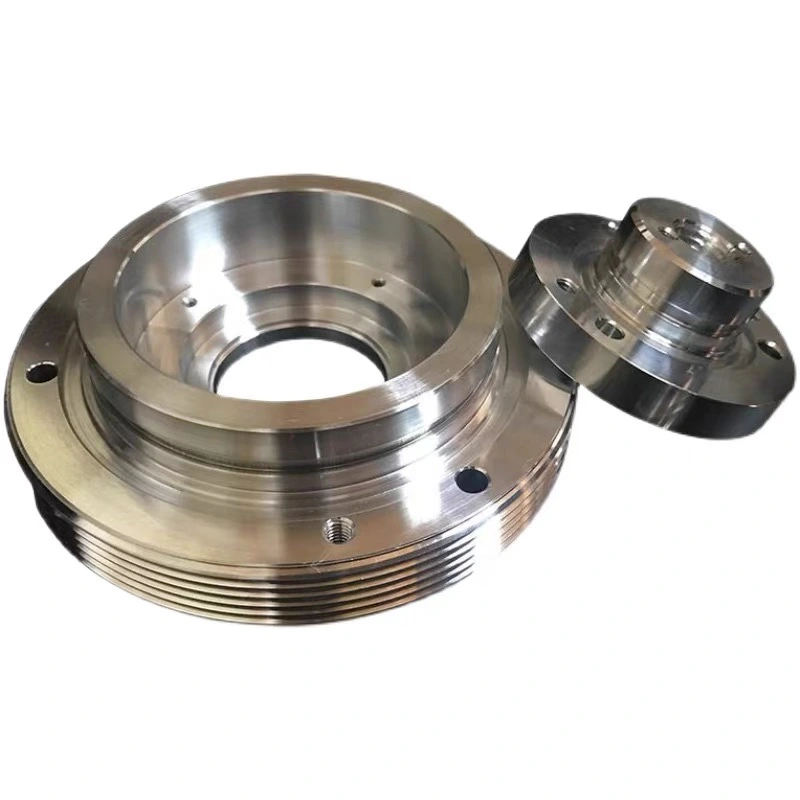

Metal Motor Parts

Material: 45 steel,aluminum alloy,stainless steel, plastic,brass

Processing techniques: CNC, EDM, turning, five axis machining, stamping,hobbing, milling, grinding, drilling, tapping, reaming, pulling, cutting, etc

Finish:Polishing, painting, anodizing,sandblasting, plating ,blackening, electrophoresis, QPQ ,wire drawing

- Product Description

Metal Motor Parts: Precision-Engineered Solutions for High-Performance Applications

Welcome to Dongguan Junsion Precision Hardware Co;Ltd, your trusted manufacturer and supplier of high-quality Metal Motor Parts. With our advanced precision machining capabilities and commitment to excellence, we deliver custom-engineered components that meet the most demanding specifications. Our products are designed to enhance performance, reliability, and efficiency across various industries, including automotive, industrial machinery, and robotics.

Description

At Junsion, we specialize in crafting precision products that form the backbone of modern machinery. Our components include:

- Rotor and Stator Assemblies

- Shaft Couplings and Bearings

- Motor Housings and End Shields

- Commutator Segments

- Brush Holders and Terminals

Each part is meticulously engineered to ensure optimal performance, durability, and seamless integration into your motor systems.

| Material | 1) Aluminum: AL 6061-T6, 6063, 7075-T etc. |

| 2) Stainless steel: 303,304,316L, 17-4(SUS630) etc. | |

| 3) Steel: 4140, Q235, Q345B,20#,45# etc. | |

| 4) Titanium: TA1,TA2/GR2, TA4/GR5, TC4, TC18 etc. | |

| 5) Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc. | |

| 5) Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc. | |

| Finish | Sandblasting, Anodize color, Blackenning, Zinc/Nickl Plating, Polish. |

| Power coating, Passivation PVD, Titanium Plating, Electrogalvanizing. | |

| Electroplating chromium, electrophoresis, QPQ(Quench-Polish-Quench). | |

| Electro Polishing,Chrome Plating, Knurl, Laser etch Logo, etc | |

| Main Equipment | STEP,STP,GIS,CAD,PDF,DWG,DXF etc or samples. |

| Tolerance | +/-0.01mm ~ +/-0.05mm |

| Surface roughness | Ra 0.1~3.2 |

| Inspection | Complete inspection lab with Micrometer, Optical Comparator, Caliper Vernier,CMM. |

| Depth Caliper Vernier, Universal Protractor, Clock Gauge, Internal Centigrade Gauge | |

| Capacity | CNC turning work range: φ0.5mm-φ150mm*300mm. |

| CNC milling work range: 510mm*1020mm*500mm. |

Key Features

- Tight Tolerances: Precision up to ±0.01mm

- Material Versatility: Stainless Steel, Aluminum, Copper, and more

- Custom Designs: Tailored to your specific requirements

- Excellent Thermal Management

- Vibration Resistance

- Enhanced Electrical Conductivity

Surface Treatment

To enhance performance and longevity, we offer various surface treatments for our Metal Motor Parts:

- Anodizing (for aluminum components)

- Electroplating (Nickel, Chrome, Zinc)

- Powder Coating

- Heat Treatment

- Passivation (for stainless steel)

These treatments improve corrosion resistance, wear properties, and aesthetic appeal, ensuring your motor parts perform reliably in diverse operating conditions.

Drawing Guide

For optimal results, please provide:

- Detailed 2D or 3D CAD drawings

- Material specifications

- Tolerance requirements

- Surface finish expectations

- Quantity needed

- Any special performance criteria

Our engineering team will review your drawings and offer suggestions for manufacturability and cost-efficiency if needed.

Production Process

- Design Review: Our engineers analyze your specifications and optimize for production.

- Material Selection: We source high-quality, RoHS-compliant materials.

- CNC Machining: State-of-the-art equipment ensures precision and consistency.

- Quality Control: Rigorous in-process inspections maintain standards.

- Surface Treatment: Application of specified finishes.

- Final Inspection: Comprehensive checks using advanced measurement tools.

- Packaging: Secure packaging to prevent damage during shipping.

Quality Certification

Junsion is committed to maintaining the highest quality standards:

- ISO 9001:2015 Certified Quality Management System

- RoHS Compliance

- REACH Compliance

- Regular third-party audits and testing

Shipping and Delivery

We understand the importance of timely delivery in your supply chain:

- Sample delivery within 3 days

- Mass production orders: 7-15 days lead time

- Global shipping capabilities

- Trackable logistics for real-time updates

Why Choose Us?

- Expertise: Over a decade of experience in precision metal fabrication

- One-Stop Solution: From prototyping to mass production

- Quality Assurance: Strict quality control at every stage

- Customization: Flexible manufacturing to meet unique requirements

- Competitive Pricing: Optimized processes for cost-effectiveness

- Reliable Partner: Trusted by 500+ global clients

FAQ

Q: What is the minimum order quantity (MOQ) for the products?

A: Our MOQ varies based on the complexity of the part. For standard components, it's typically 100 pieces, but we're flexible for custom orders.

Q: Can you provide samples before mass production?

A: Absolutely! We offer prototyping services and can provide samples for approval before proceeding with bulk orders.

Q: What materials do you use for the products?

A: We work with a wide range of materials, including stainless steel, aluminum, copper, and specialized alloys. The choice depends on your specific requirements.

Q: How do you ensure the quality of your products?

A: We employ a comprehensive quality control system, including incoming material inspection, in-process checks, and final product testing using advanced equipment.

Contact & Support

Ready to elevate your motor performance with our precision-engineered Metal Motor Parts? Contact our expert team today:

- Email: Lock@junsion.com.cn, echo@junsion.com.cn, or evelyn@junsion.com.cn.

Let Junsion be your trusted partner in delivering high-quality, custom products that drive your success. Request a quote now and experience the difference of working with a leader in precision manufacturing.

_1755499208108.jpg)

_1755499208195.jpg)

_1755499208277.jpg)

_1755499208268.jpg)

_1755499208227.jpg)

_1755499208269.jpg)

_1755496585422.jpg)