Tungsten Carbide Inserts

Material: 6063/7075/6061 aluminum alloy

Processing techniques: CNC, EDM, turning, five axis machining

Finish:Polishing, painting, anodizing,sandblasting, plating ,blackening, electrophoresis, QPQ ,wire drawing

Application fields: Automation equipment,Vehicle,medical,aerospace, AI Intelligent ,home appliances, robots

- Product Description

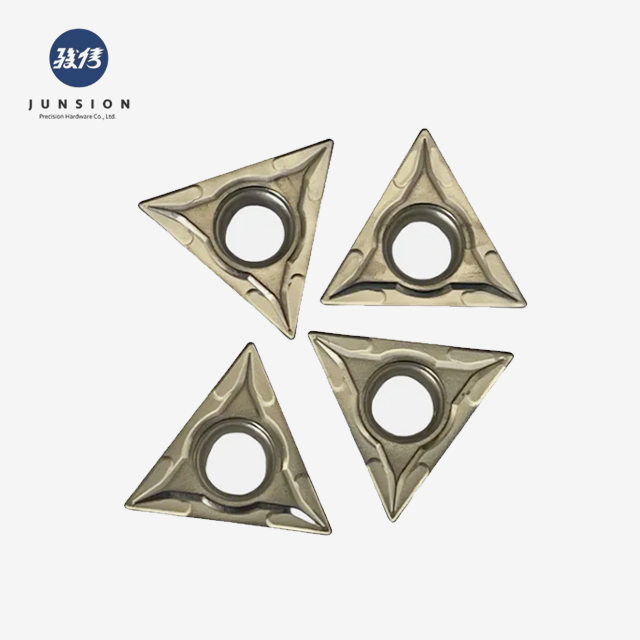

Tungsten Carbide Inserts: Precision-Engineered for Superior Performance

At Dongguan Junsion Precision Hardware Co., Ltd., we pride ourselves on being a leading manufacturer and supplier of high-quality Tungsten Carbide Inserts. Our cutting-edge equipment and sophisticated precision machining skills enable us to create inserts with tolerances as small as ±0.01mm, guaranteeing unmatched accuracy and consistency. We provide products that satisfy the stringent requirements of sectors including metallurgy, automotive, and aerospace thanks to our extensive material variety and one-stop custom solutions.

_1755503486383.jpg)

_1755503486470.jpg)

_1755503486566.png)

Description

Our high-quality products are made to perform exceptionally well in demanding machining applications. These inserts are perfect for high-speed cutting operations because of their remarkable toughness, wear resistance, and thermal stability.

| Material | 1) Aluminum: AL 6061-T6, 6063, 7075-T etc. |

| 2) Stainless steel: 303,304,316L, 17-4(SUS630) etc. | |

| 3) Steel: 4140, Q235, Q345B,20#,45# etc. | |

| 4) Titanium: TA1,TA2/GR2, TA4/GR5, TC4, TC18 etc. | |

| 5) Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc. | |

| 5) Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc. | |

| Finish | Sandblasting, Anodize color, Blackenning, Zinc/Nickl Plating, Polish. |

| Power coating, Passivation PVD, Titanium Plating, Electrogalvanizing. | |

| Electroplating chromium, electrophoresis, QPQ(Quench-Polish-Quench). | |

| Electro Polishing,Chrome Plating, Knurl, Laser etch Logo, etc | |

| Main Equipment | STEP,STP,GIS,CAD,PDF,DWG,DXF etc or samples. |

| Tolerance | +/-0.01mm ~ +/-0.05mm |

| Surface roughness | Ra 0.1~3.2 |

| Inspection | Complete inspection lab with Micrometer, Optical Comparator, Caliper Vernier,CMM. |

| Depth Caliper Vernier, Universal Protractor, Clock Gauge, Internal Centigrade Gauge | |

| Capacity | CNC turning work range: φ0.5mm-φ150mm*300mm. |

| CNC milling work range: 510mm*1020mm*500mm. |

Key Features

- Superior hardness and durability

- Excellent heat resistance

- Precision-ground cutting edges

- Various grades and geometries available

- Compatible with multiple machining operations

Surface Treatment

To enhance the performance and longevity of our products, we offer a range of advanced surface treatments:

- PVD Coating: Improves wear resistance and reduces friction

- CVD Coating: Provides excellent chemical stability and adhesion

- AlTiN Coating: Offers high oxidation resistance for high-temperature applications

- Polished Edges: Enhances chip flow and reduces built-up edge formation

Drawing Guide

We understand the importance of precision in your manufacturing processes. Our engineering team works closely with clients to develop custom Tungsten Carbide Inserts based on your specific requirements. We can produce inserts according to your drawings or samples, ensuring a perfect fit for your tooling systems.

Production Process

Our rigorous production process guarantees consistent quality:

- Material Selection: Sourcing high-grade tungsten carbide powders

- Powder Preparation: Mixing and milling to achieve optimal particle size distribution

- Pressing: Forming the insert shape under high pressure

- Sintering: Heat treatment to achieve final hardness and density

- Grinding: Precision grinding of cutting edges and surfaces

- Coating: Applying advanced surface treatments as required

- Quality Control: Rigorous inspection and testing at each stage

Quality Certification

Junxion is committed to maintaining the highest quality standards:

- ISO 9001:2015 certified quality management system

- RoHS compliant materials and processes

- Strict IQC, IPQC, and OQC protocols

- Advanced testing equipment including 2.5D projectors and hardness testers

Shipping and Delivery

We understand the importance of timely delivery in your production schedules:

- Sample delivery within 3 days

- Mass production orders shipped within 7-15 days

- Global logistics network ensuring efficient delivery worldwide

- Secure packaging to prevent damage during transit

Why Choose Us?

- Industry Expertise: Over 500 satisfied clients across various sectors

- Custom Solutions: Tailored inserts to meet your specific application needs

- Competitive Pricing: Bulk order discounts and cost-effective solutions

- Technical Support: Expert guidance on insert selection and optimization

- Reliable Partner: Long-term cooperation focused on your success

FAQ

Q: What is the minimum order quantity for the products?

A: Our MOQ varies depending on the specific insert type and customization requirements. Please contact us for detailed information.

Q: Can you produce custom geometries for specialized applications?

A: Yes, our engineering team can work with you to design and manufacture custom inserts tailored to your unique needs.

Q: What is the typical lead time for a custom order?

A: Lead times vary based on complexity and quantity. Generally, we can deliver custom orders within 2-4 weeks.

Q: Do you offer sample inserts for testing?

A: Yes, we provide sample inserts for evaluation. Contact our sales team to arrange for samples.

Contact & Support

Ready to enhance your machining performance with our Tungsten Carbide Inserts? Our dedicated team is here to assist you:

- Email: Lock@junsion.com.cn, echo@junsion.com.cn, or evelyn@junsion.com.cn.

Experience the Junsion difference today. Let us be your trusted partner in precision machining solutions.

_1755503486383.jpg)

_1755503486460.jpg)

_1755503486470.jpg)

_1755503486566.png)

_1755502812953.jpg)

_1755501595589.jpg)

_1755504107727.jpg)