Metal Solenoid Valve

Material: 316/304/303/410 stainless steel

Processing techniques: CNC, turning, five axis machining, stamping

Finish:Polishing, painting, anodizing,sandblasting, plating , electrophoresis

Application fields: Automation equipment,Vehicle,medical,aerospace, AI Intelligent ,home appliances, robots,

- Product Description

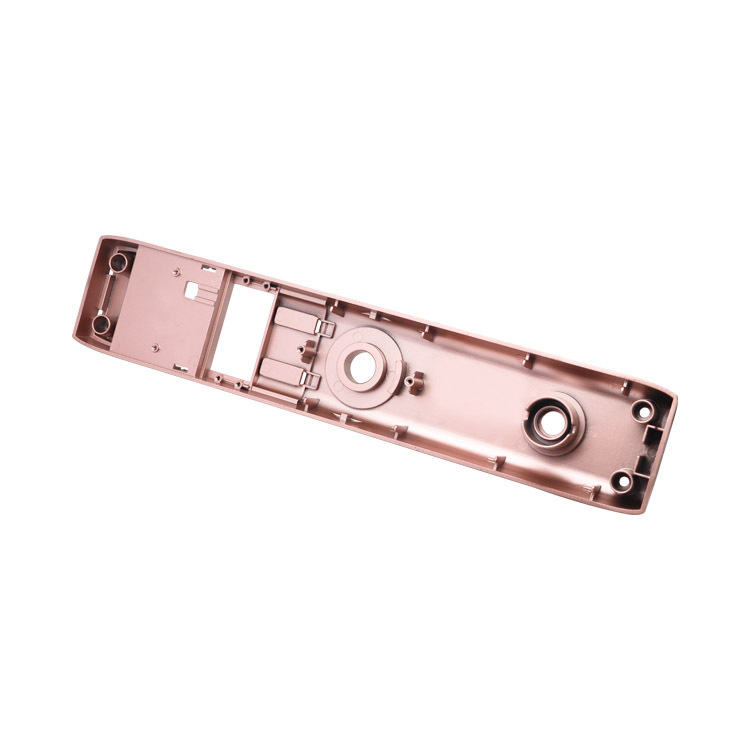

Metal Solenoid Valves: Precision-Engineered Flow Control Solutions

Dongguan Junsion Precision Hardware Co., Ltd. is a leading manufacturer and supplier of high-quality metal solenoid valves. Our advanced precision machining capabilities and state-of-the-art equipment allow us to produce valves with tolerances up to ±0.01mm. Junsion's products offer unparalleled reliability, durability, and performance for various industrial applications.

_1755504107727.jpg)

Description

Our products are designed to provide precise control over fluid flow in a wide range of industrial systems. These electromagnetic valves use an electric current to open or close a valve, allowing for automated and remote operation.

| Material | 1) Aluminum: AL 6061-T6, 6063, 7075-T etc. |

| 2) Stainless steel: 303,304,316L, 17-4(SUS630) etc. | |

| 3) Steel: 4140, Q235, Q345B,20#,45# etc. | |

| 4) Titanium: TA1,TA2/GR2, TA4/GR5, TC4, TC18 etc. | |

| 5) Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc. | |

| 5) Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc. | |

| Finish | Sandblasting, Anodize color, Blackenning, Zinc/Nickl Plating, Polish. |

| Power coating, Passivation PVD, Titanium Plating, Electrogalvanizing. | |

| Electroplating chromium, electrophoresis, QPQ(Quench-Polish-Quench). | |

| Electro Polishing,Chrome Plating, Knurl, Laser etch Logo, etc | |

| Main Equipment | STEP,STP,GIS,CAD,PDF,DWG,DXF etc or samples. |

| Tolerance | +/-0.01mm ~ +/-0.05mm |

| Surface roughness | Ra 0.1~3.2 |

| Inspection | Complete inspection lab with Micrometer, Optical Comparator, Caliper Vernier,CMM. |

| Depth Caliper Vernier, Universal Protractor, Clock Gauge, Internal Centigrade Gauge | |

| Capacity | CNC turning work range: φ0.5mm-φ150mm*300mm. |

| CNC milling work range: 510mm*1020mm*500mm. |

Key Features

- Robust Construction: Made from high-grade materials like stainless steel and aluminum

- Versatile Applications: Suitable for water, oil, gas, and chemical processing

- High Precision: Accurate flow control with minimal leakage

- Fast Response Time: Quick opening and closing for efficient operation

- Long Lifespan: Durable design for extended service life

- Customizable Options: Available in various sizes, configurations, and pressure ratings

Surface Treatment

To enhance performance and longevity, we offer multiple surface treatment options for our products:

- Anodizing: Improves corrosion resistance and hardness of aluminum components

- Electroplating: Provides a protective layer for enhanced durability

- Sandblasting: Creates a uniform surface finish and improves adhesion for coatings

- Brushing: Offers a sleek, professional appearance and reduces fingerprint visibility

Drawing Guide

Our engineering team works closely with clients to develop custom product solutions. We accept:

- 2D/3D CAD files (AutoCAD, SolidWorks, etc.)

- Technical drawings with detailed specifications

- Existing samples for reverse engineering

- Rough sketches with basic requirements for collaborative design

Production Process

- Design & Engineering: Optimize valve design for performance and manufacturability

- CNC Machining: Precision-cut valve bodies and components

- Assembly: Integrate solenoid coils and other internal parts

- Testing: Rigorous quality control checks for pressure, flow, and response time

- Surface Treatment: Apply specified finishes for enhanced durability

- Final Inspection: Ensure compliance with all specifications and standards

Quality Certification

Our metal solenoid valves meet or exceed industry standards, including:

- ISO 9001:2015 Quality Management System

- RoHS Compliance for environmental safety

- CE Marking for European market requirements

- ATEX Certification for explosive atmospheres (where applicable)

Shipping and Delivery

- Fast Turnaround: Sample delivery within 3 days, mass production in 7-15 days

- Global Logistics: Reliable shipping to Europe, North America, Asia, and beyond

- Packaging Options: Standard or custom packaging for safe transportation

- Order Tracking: Real-time updates on your shipment status

Why Choose Us?

- One-Stop Solution: From prototyping to mass production

- Advanced Technology: State-of-the-art CNC machinery for precise manufacturing

- Quality Assurance: Strict quality control throughout the production process

- Industry Expertise: Serving 500+ satisfied clients across various sectors

- Customization: Tailored solutions to meet your specific requirements

- Competitive Pricing: Cost-effective options for bulk orders

- Responsive Support: Dedicated customer service team for all your inquiries

FAQ

Q: What is the minimum order quantity (MOQ) for the products?

A: Our MOQ varies depending on the valve specifications. Contact us for a customized quote.

Q: Can you provide samples before mass production?

A: Yes, we offer sample production to ensure the valves meet your requirements.

Q: What is the typical lead time for custom products?

A: Lead times vary based on complexity and quantity. Generally, we can deliver within 7-15 days for mass production orders.

Q: Do you offer design assistance for the products?

A: Absolutely! Our engineering team can help optimize your valve design for performance and manufacturability.

Q: What industries do you typically serve with your products?

A: Our valves are used in manufacturing, oil & gas, water treatment, chemical processing, automotive, and HVAC industries, among others.

Contact & Support

Ready to elevate your fluid control systems with Junsion's premium metal solenoid valves? Our team is here to assist you every step of the way. Contact us today to discuss your specific requirements and discover how our precision-engineered solutions can benefit your operations.

Email: Lock@junsion.com.cn, echo@junsion.com.cn, or evelyn@junsion.com.cn.

Experience the difference of Junsion's products – where precision meets reliability in flow control technology.

_1755504107727.jpg)

_1755504107751.jpg)

_1755504107753.jpg)

_1755504107835.jpg)

_1755504107861.jpg)

_1755501595589.jpg)