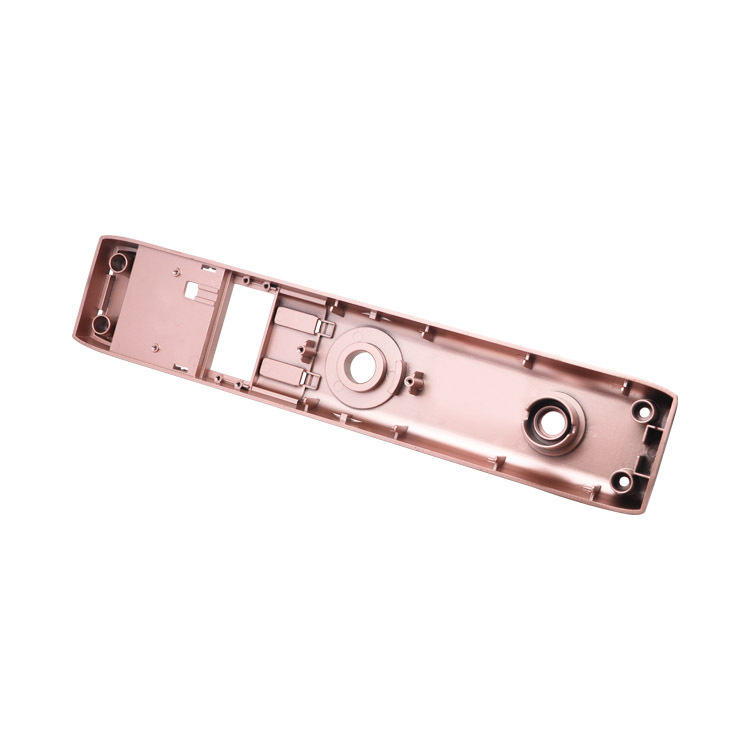

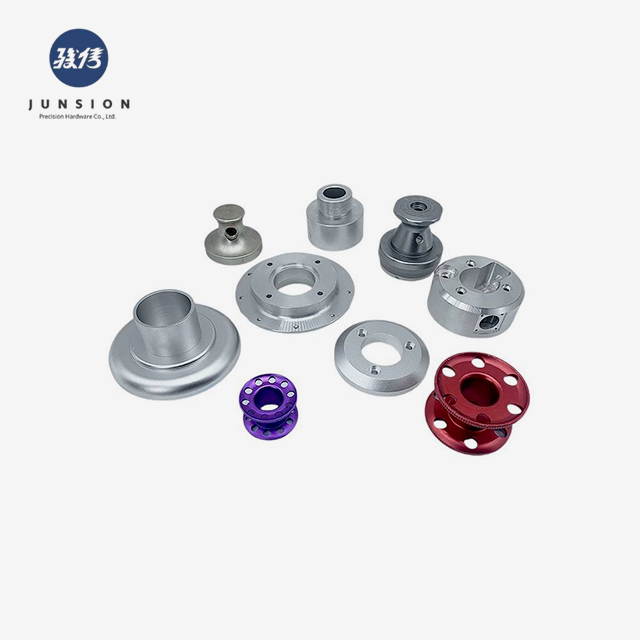

CNC Machining Aluminum Alloy Parts

Material: 6063/7075/6061 aluminum alloy

Processing techniques: CNC, EDM, turning, five axis machining

Finish:Polishing, painting, anodizing,sandblasting, plating ,blackening, electrophoresis, QPQ ,wire drawing

Application fields: Automation equipment,Vehicle,medical,aerospace, AI Intelligent ,home appliances, robots

- Product Description

CNC Machining Aluminum Alloy Parts: Precision Solutions for Your Manufacturing Needs

Dongguan Junsion Precision Hardware Co., Ltd. is a leading manufacturer and supplier of CNC Machining Aluminum Alloy Parts. We can make high-quality parts for many businesses because we are very good at precise machining and have a lot of different metal alloys to choose from. We're proud of the fact that we can meet your needs quickly, come up with unique solutions, and keep a close eye on quality.

Description

Our products are made with great care to meet the best standards of accuracy and performance. We use cutting edge CNC lathes and turning centers to make parts with accuracy of up to ±0.01mm. Our expertise covers a wide range of aluminum alloys, including:

- 6061: Excellent corrosion resistance and machinability

- 7075: High strength-to-weight ratio, ideal for aerospace applications

- 5052: Good weldability and fatigue strength

- 2024: High strength and excellent fatigue resistance

Whether you need prototypes or high-volume production runs, our flexible manufacturing processes can accommodate your needs. We specialize in creating complex geometries, intricate features, and tight tolerances that many other suppliers can't match.

| Material | 1) Aluminum: AL 6061-T6, 6063, 7075-T etc. |

| 2) Stainless steel: 303,304,316L, 17-4(SUS630) etc. | |

| 3) Steel: 4140, Q235, Q345B,20#,45# etc. | |

| 4) Titanium: TA1,TA2/GR2, TA4/GR5, TC4, TC18 etc. | |

| 5) Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc. | |

| 5) Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc. | |

| Finish | Sandblasting, Anodize color, Blackenning, Zinc/Nickl Plating, Polish. |

| Power coating, Passivation PVD, Titanium Plating, Electrogalvanizing. | |

| Electroplating chromium, electrophoresis, QPQ(Quench-Polish-Quench). | |

| Electro Polishing,Chrome Plating, Knurl, Laser etch Logo, etc | |

| Main Equipment | STEP,STP,GIS,CAD,PDF,DWG,DXF etc or samples. |

| Tolerance | +/-0.01mm ~ +/-0.05mm |

| Surface roughness | Ra 0.1~3.2 |

| Inspection | Complete inspection lab with Micrometer, Optical Comparator, Caliper Vernier,CMM. |

| Depth Caliper Vernier, Universal Protractor, Clock Gauge, Internal Centigrade Gauge | |

| Capacity | CNC turning work range: φ0.5mm-φ150mm*300mm. |

| CNC milling work range: 510mm*1020mm*500mm. |

Surface Treatment

To enhance the performance and aesthetics of your products, we offer various surface treatment options:

- Anodizing: Improves corrosion resistance and creates a decorative finish

- Hard anodizing: Provides superior wear resistance and hardness

- Powder coating: Offers a durable, attractive finish in a wide range of colors

- Brushing: Creates a sleek, modern appearance

- Polishing: Achieves a mirror-like finish for aesthetic or functional purposes

Our experts can recommend the best surface treatment based on your specific application and requirements.

Drawing Guide

To ensure the highest quality and accuracy for your CNC Machining Aluminum Alloy Parts, please provide:

- Detailed 2D or 3D CAD drawings (preferred formats: STEP, IGES, or DWG)

- Material specifications and grade

- Required tolerances and surface finish

- Quantity needed and lead time

- Any special requirements or certifications

Our engineering team is available to assist with design optimization and material selection to improve manufacturability and reduce costs.

Production Process

- Design Review: Our engineers analyze your drawings and suggest optimizations if needed.

- Material Selection: We source high-quality aluminum alloys that meet your specifications.

- CNC Programming: Our skilled programmers create efficient machining paths.

- Machining: State-of-the-art CNC machines produce your parts with precision.

- Quality Control: Rigorous inspections ensure parts meet all specifications.

- Surface Treatment: If required, parts undergo the specified finishing process.

- Final Inspection: A comprehensive check before packaging and shipping.

Quality Certification

We maintain strict quality control throughout our production process:

- ISO 9001:2015 certified quality management system

- RoHS compliance for all materials

- In-process quality control (IPQC) and final quality control (FQC) inspections

- Advanced measuring equipment including CMMs and optical comparators

Shipping and Delivery

We offer flexible shipping options to meet your needs:

- Express shipping for urgent orders (3-5 days)

- Standard air freight (7-10 days)

- Sea freight for large orders (20-30 days)

Our logistics team ensures proper packaging to protect your parts during transit.

Why Choose Us?

- Advanced Precision Machining: State-of-the-art equipment for superior accuracy

- One-Stop Custom Solutions: From prototyping to mass production

- Wide Material Selection: Various aluminum alloys to suit your needs

- Fast Turnaround: Samples in 3 days, production in 7-15 days

- Strict Quality Control: Comprehensive inspections at every stage

- Global Experience: Serving 500+ satisfied clients worldwide

- Customer-Centric Approach: Responsive communication and support

FAQ

Q: What is the minimum order quantity for CNC machined aluminum parts?

A: We can accommodate orders as low as 10 pieces for prototypes and small runs.

Q: Can you provide material certifications?

A: Yes, we can provide material certifications upon request.

Q: Do you offer design assistance?

A: Our engineering team can provide design optimization suggestions to improve manufacturability and reduce costs.

Contact & Support

Ready to start your next project with high-quality CNC Machining Aluminum Alloy Parts? Contact our expert team today:

Email: Lock@junsion.com.cn, echo@junsion.com.cn, or evelyn@junsion.com.cn.

Let Dongguan Junsion Precision Hardware Co., Ltd. be your trusted partner for precision aluminum components. We're committed to delivering excellence in every part we produce.

_1755670903756.jpg)

_1755503486383.jpg)