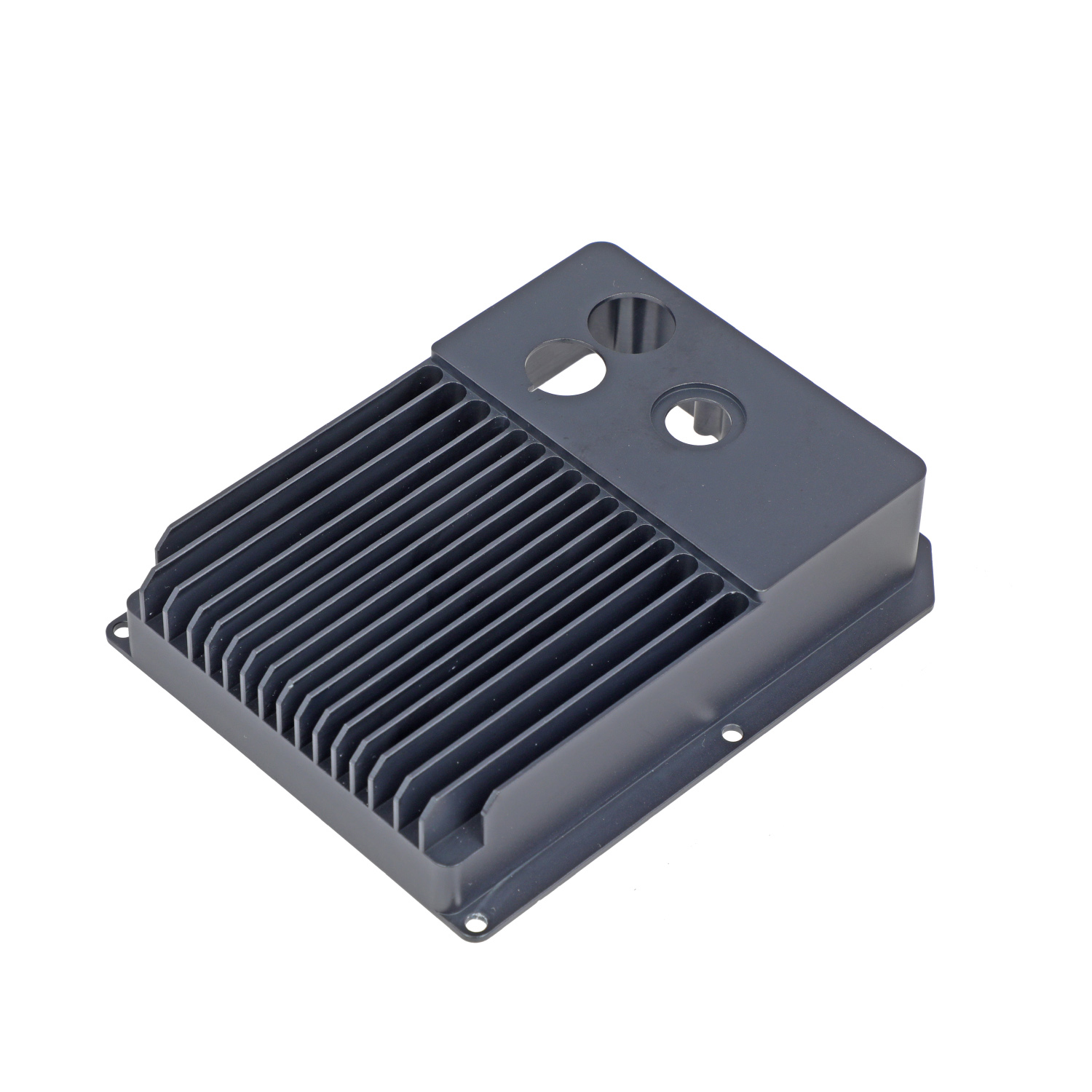

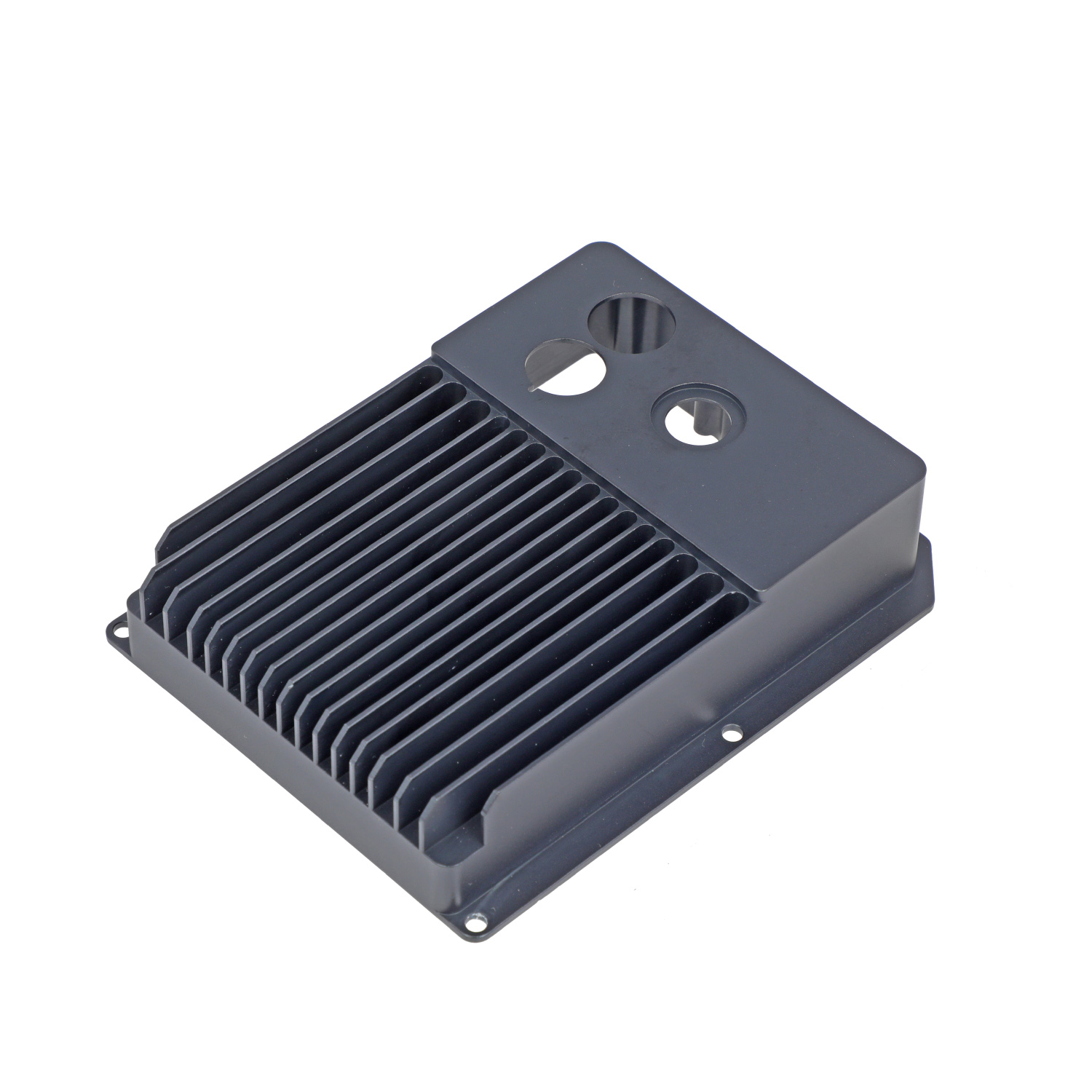

CNC Semiconductor Parts

Material:aluminum alloy, stainless steel, plastic,brass

Processing techniques: CNC, EDM, turning, five axis machining, stamping ,hobbing, milling, grinding, drilling, tapping, reaming, pulling, cutting, etc

Finish:Polishing, painting, anodizing,sandblasting, plating ,blackening, electrophoresis, QPQ ,wire drawing

- Product Description

CNC Semiconductor Parts: Precision Solutions for Advanced Manufacturing

At Dongguan Junsion Precision Hardware Co., Ltd., we specialize in producing high-quality CNC Semiconductor Parts that meet the exacting standards of the semiconductor industry. Our advanced machining capabilities, coupled with stringent quality control, ensure we deliver components with tolerances up to ±0.01mm. As a trusted supplier to global OEMs and contract manufacturers, we offer a comprehensive range of the products tailored to your specific needs.

_1755567637543.jpg)

Description

Our products are meticulously crafted to support various semiconductor manufacturing processes. We offer:

- Wafer Handling Components: Precision-machined parts for wafer transfer systems, ensuring contamination-free handling.

- Etching Tool Components: Corrosion-resistant parts for plasma etching equipment.

- Test Socket Components: High-precision pins and housings for semiconductor testing.

- Heat Sink Components: Custom-designed parts for thermal management in semiconductor devices.

- Vacuum Chamber Components: Ultra-clean parts for deposition and ion implantation processes.

| Material | 1) Aluminum: AL 6061-T6, 6063, 7075-T etc. |

| 2) Stainless steel: 303,304,316L, 17-4(SUS630) etc. | |

| 3) Steel: 4140, Q235, Q345B,20#,45# etc. | |

| 4) Titanium: TA1,TA2/GR2, TA4/GR5, TC4, TC18 etc. | |

| 5) Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc. | |

| 5) Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc. | |

| Finish | Sandblasting, Anodize color, Blackenning, Zinc/Nickl Plating, Polish. |

| Power coating, Passivation PVD, Titanium Plating, Electrogalvanizing. | |

| Electroplating chromium, electrophoresis, QPQ(Quench-Polish-Quench). | |

| Electro Polishing,Chrome Plating, Knurl, Laser etch Logo, etc | |

| Main Equipment | STEP,STP,GIS,CAD,PDF,DWG,DXF etc or samples. |

| Tolerance | +/-0.01mm ~ +/-0.05mm |

| Surface roughness | Ra 0.1~3.2 |

| Inspection | Complete inspection lab with Micrometer, Optical Comparator, Caliper Vernier,CMM. |

| Depth Caliper Vernier, Universal Protractor, Clock Gauge, Internal Centigrade Gauge | |

| Capacity | CNC turning work range: φ0.5mm-φ150mm*300mm. |

| CNC milling work range: 510mm*1020mm*500mm. |

Materials we commonly use include:

- High-purity aluminum alloys (6061-T6, 7075)

- Stainless steel (316L, 304)

- Titanium alloys

- High-performance plastics (PEEK, POM)

All our products are manufactured to meet or exceed industry standards, including SEMI and RoHS compliance.

Surface Treatment

To enhance performance and longevity, we offer various surface treatments:

- Anodizing: For improved corrosion resistance and surface hardness.

- Electroless Nickel Plating: Provides uniform coating for complex geometries.

- Passivation: Enhances corrosion resistance of stainless steel components.

- Plasma Spray Coating: For thermal and wear-resistant surfaces.

- Chemical Etching: Creates micro-textures for specific applications.

Our engineering team can recommend the optimal surface treatment based on your application requirements.

Drawing Guide

To ensure accurate production of your CNC Semiconductor Parts, please provide:

- Detailed 2D or 3D CAD drawings (preferably in STEP or IGES format)

- Material specifications

- Tolerance requirements

- Surface finish requirements

- Any special features or critical dimensions

- Quantity needed and lead time expectations

Our team is ready to assist with design optimization for manufacturability and cost-efficiency.

Production Process

Our state-of-the-art facility follows a rigorous production process:

- Design Review & Optimization

- Material Sourcing & Verification

- CNC Programming & Setup

- Precision Machining

- In-Process Quality Control

- Surface Treatment (if applicable)

- Final Inspection & Metrology

- Packaging & Shipping

Each step is carefully monitored to ensure consistent quality and on-time delivery.

Quality Certification

We maintain strict quality standards, certified by:

- ISO 9001:2015 Quality Management System

- IATF 16949 (for automotive semiconductor applications)

- RoHS Compliance

Our quality assurance process includes:

- Incoming Material Inspection (IQC)

- In-Process Quality Control (IPQC)

- Final Quality Check (OQC)

We use advanced metrology equipment, including CMMs and optical comparators, to verify dimensional accuracy.

Shipping and Delivery

We understand the critical nature of semiconductor manufacturing schedules. Our logistics capabilities include:

- Express shipping options for urgent orders

- Customized packaging to protect sensitive components

- Real-time order tracking

- Flexible delivery schedules to align with your production needs

Typical lead times:

- Prototypes: 3-5 days

- Production runs: 7-15 days (depending on complexity and quantity)

Why Choose Us?

- Semiconductor Industry Expertise: Over a decade of experience serving global semiconductor manufacturers.

- Advanced Machining Capabilities: State-of-the-art CNC equipment for ultra-precise parts.

- Comprehensive Quality System: Ensuring consistency and reliability in every component.

- Flexible Production: From prototypes to high-volume orders, we adapt to your needs.

- Engineering Support: Collaborative approach to optimize designs for manufacturability.

- Global Reach: Serving clients across North America, Europe, and Asia.

FAQ

Q: What is your minimum order quantity for the products?

A: We accommodate orders of all sizes, from single prototypes to large production runs.

Q: Can you provide material certificates?

A: Yes, we provide full material traceability and certificates upon request.

Q: Do you offer expedited production for urgent orders?

A: Absolutely. We can prioritize urgent orders. Please contact us for specific lead times.

Q: How do you ensure cleanliness for critical semiconductor components?

A: We have a dedicated clean room for final processing and packaging of sensitive parts.

Contact & Support

Ready to elevate your semiconductor manufacturing with precision CNC Semiconductor Parts? Contact our team today:

Email: Lock@junsion.com.cn, echo@junsion.com.cn, or evelyn@junsion.com.cn.

Let Dongguan Junsion Precision Hardware Co., Ltd. be your trusted partner in semiconductor component manufacturing. Request a quote or consultation today!

_1755567637543.jpg)

_1755567637597.jpg)

_1763437634980.jpg)

_1755503486383.jpg)