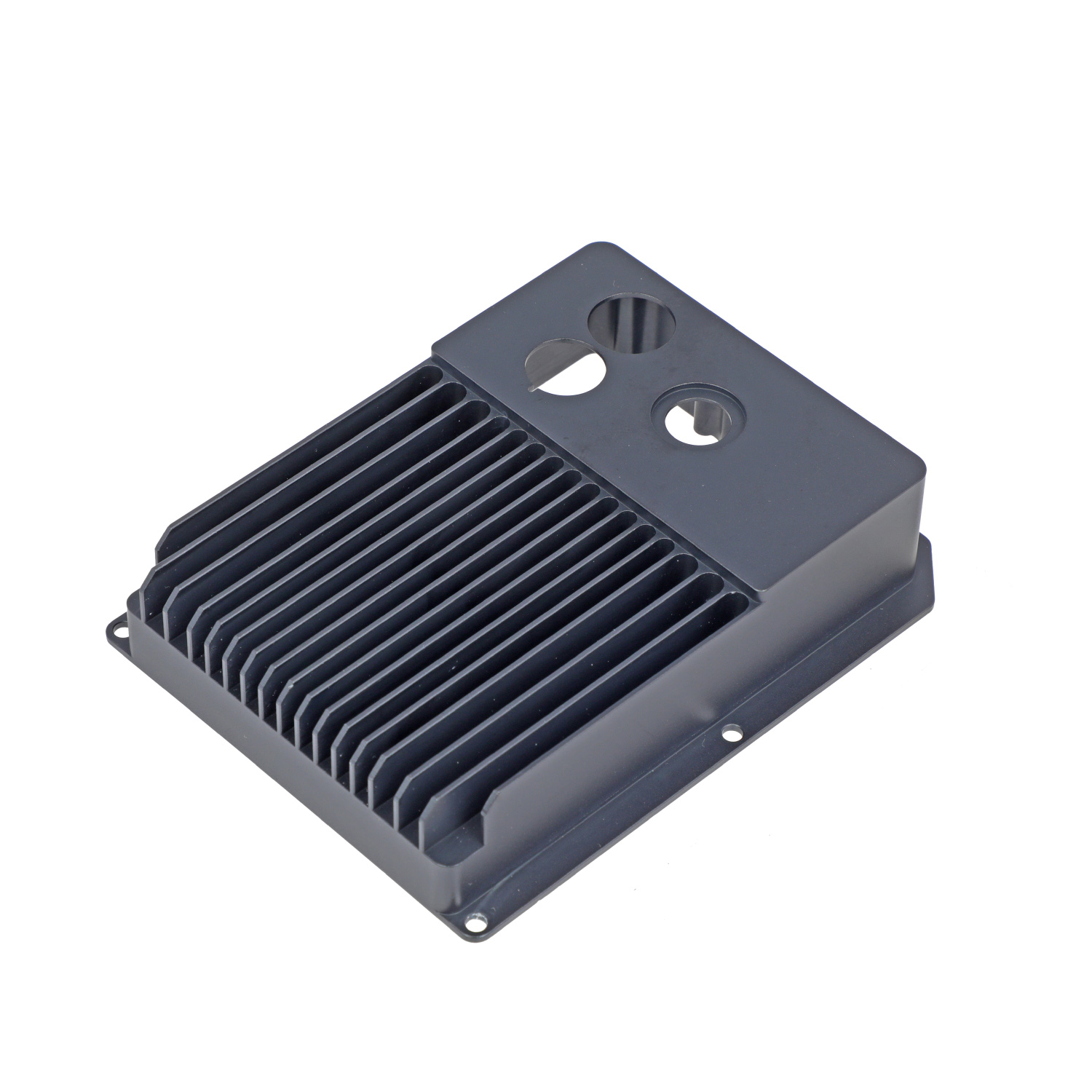

Aluminum Shaft Part

Material: 45 steel,aluminum alloy,stainless steel, plastic,brass

Processing techniques: CNC, EDM, turning, five axis machining, stamping,hobbing, milling, grinding, drilling, tapping, reaming, pulling, cutting, etc

Finish:Polishing, painting, anodizing,sandblasting, plating ,blackening, electrophoresis, QPQ ,wire drawing

- Product Description

Dongguan Junsion Precision Hardware Co., Ltd: Your Trusted Partner in Aluminum Shaft Parts

At Junsion, we pride ourselves on delivering superior Aluminum Shaft Parts that combine durability, precision, and cost-effectiveness. Our experienced staff and state-of-the-art building make sure that every part we make meets or beats industry standards. We've become a preferred supplier for companies around the world looking for reliable aluminum parts by focusing on new ideas and quality.

_1755495773511.jpg)

Description

The engineering behind our goods makes them work perfectly in a wide range of situations. It is made from high-quality metal alloys, these components offer:

- Exceptional strength-to-weight ratio

- Excellent corrosion resistance

- Superior thermal conductivity

- Precise dimensional accuracy (up to ±0.01mm tolerances)

- Customizable designs to meet specific requirements

Whether you need shafts for electric motors, robotics, or industrial machinery, our parts are designed to deliver consistent performance and longevity.

| Material | 1) Aluminum: AL 6061-T6, 6063, 7075-T etc. |

| 2) Stainless steel: 303,304,316L, 17-4(SUS630) etc. | |

| 3) Steel: 4140, Q235, Q345B,20#,45# etc. | |

| 4) Titanium: TA1,TA2/GR2, TA4/GR5, TC4, TC18 etc. | |

| 5) Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc. | |

| 5) Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc. | |

| Finish | Sandblasting, Anodize color, Blackenning, Zinc/Nickl Plating, Polish. |

| Power coating, Passivation PVD, Titanium Plating, Electrogalvanizing. | |

| Electroplating chromium, electrophoresis, QPQ(Quench-Polish-Quench). | |

| Electro Polishing,Chrome Plating, Knurl, Laser etch Logo, etc | |

| Main Equipment | STEP,STP,GIS,CAD,PDF,DWG,DXF etc or samples. |

| Tolerance | +/-0.01mm ~ +/-0.05mm |

| Surface roughness | Ra 0.1~3.2 |

| Inspection | Complete inspection lab with Micrometer, Optical Comparator, Caliper Vernier,CMM. |

| Depth Caliper Vernier, Universal Protractor, Clock Gauge, Internal Centigrade Gauge | |

| Capacity | CNC turning work range: φ0.5mm-φ150mm*300mm. |

| CNC milling work range: 510mm*1020mm*500mm. |

Surface Treatment

To enhance the functionality and aesthetics of our products, we offer a range of surface treatments, including:

- Anodizing: Improves corrosion resistance and allows for color customization

- Hard anodizing: Increases surface hardness for improved wear resistance

- Electroplating: Enhances conductivity and provides a decorative finish

- Sandblasting: Creates a matte finish and improves adhesion for subsequent coatings

- Brushing: Offers a sleek, professional appearance

Our experts can recommend the ideal surface treatment based on your application requirements.

Drawing Guide

To ensure we meet your exact specifications, we accept:

- 2D and 3D CAD drawings (DWG, DXF, STEP formats)

- Detailed technical drawings with dimensions and tolerances

- Sample parts for reverse engineering

Our engineering team is available to assist with design optimization and material selection to maximize performance and cost-efficiency.

Production Process

Our streamlined production process for Aluminum Shaft Parts includes:

- Material selection and inspection

- CNC machining (turning, milling, drilling)

- Precision grinding for tight tolerances

- Surface treatment application

- Quality control inspection

- Packaging and shipping

Each step is carefully monitored to ensure consistent quality and timely delivery.

Quality Certification

Junsion is committed to maintaining the highest quality standards. Our products production is certified by:

- ISO 9001:2015 Quality Management System

- RoHS Compliance

- IATF 16949 (for automotive industry suppliers)

We also perform rigorous in-house testing, including dimensional inspection, material composition analysis, and functional testing to guarantee part reliability.

Shipping and Delivery

We understand the importance of timely delivery in your supply chain. Our logistics solutions include:

- Express shipping options for urgent orders

- Bulk shipping for large volume orders

- Custom packaging to protect your products during transit

- Real-time order tracking

With our efficient production scheduling, we can typically deliver samples within 3 days and complete mass production orders in 7-15 days.

Why Choose Us?

- Uncompromising quality and precision

- Customization capabilities to meet unique requirements

- Competitive pricing for both prototypes and high-volume orders

- Extensive industry experience and technical expertise

- Responsive customer service and engineering support

- Fast turnaround times to keep your projects on schedule

- Commitment to sustainability and ethical manufacturing practices

FAQ

Q: What is the minimum order quantity for the products?

A: We offer flexible MOQs to accommodate both small and large orders. Contact us for specific details.

Q: Can you produce your products according to my custom specifications?

A: Absolutely! We specialize in custom manufacturing and can produce parts to your exact requirements.

Q: What industries do you typically serve?

A: We serve a wide range of industries, including automotive, aerospace, robotics, medical equipment, and industrial machinery.

Q: How do you ensure the quality of your products?

A: We employ a rigorous quality control system, including incoming material inspection, in-process checks, and final inspection using advanced testing equipment.

Contact & Support

Ready to elevate your projects with our premium Aluminum Shaft Parts? Contact our team today for expert advice, custom quotations, or to discuss your specific needs. We're committed to providing you with the highest quality components and unparalleled service.

Email: Lock@junsion.com.cn, echo@junsion.com.cn, or evelyn@junsion.com.cn.

Let Dongguan Junsion Precision Hardware Co., Ltd be your partner in precision. Experience the difference that quality productss can make in your products and processes. Reach out now to start your journey towards manufacturing excellence!

_1755495773511.jpg)

_1755495917785.jpg)