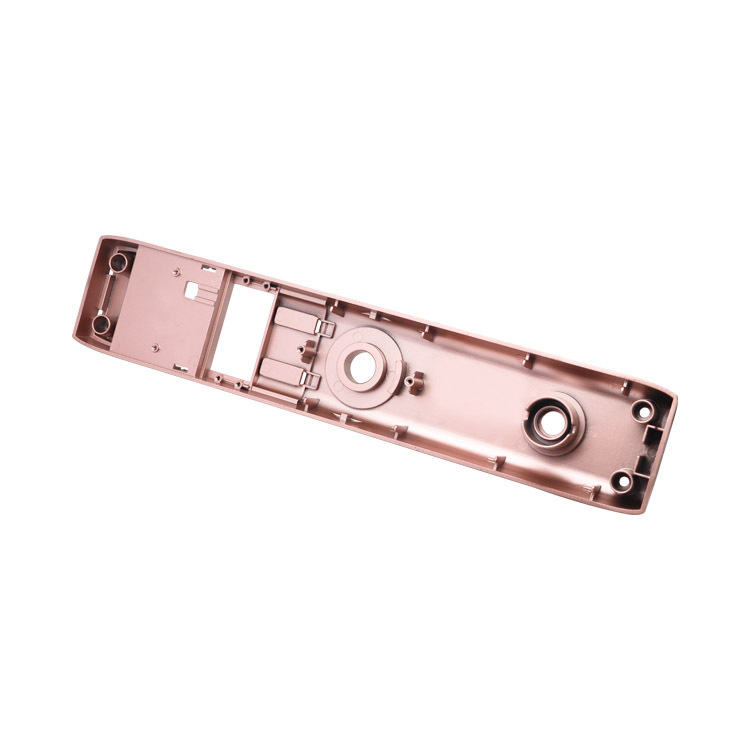

Valve Parts

Material: 316/304/303/410 stainless steel

Processing techniques: CNC, turning, five axis machining, stamping

Finish:Polishing, painting, anodizing,sandblasting, plating , electrophoresis

Application fields: Automation equipment,Vehicle,medical,aerospace, AI Intelligent ,home appliances, robots,

- Product Description

Valve Parts: Precision-Engineered Solutions for Industrial Excellence

At Dongguan Junsion Precision Hardware Co., Ltd., we specialize in manufacturing high-quality valve parts for diverse industrial applications. Our advanced machining capabilities and commitment to precision ensure that every component meets the exacting standards of our global clientele. From oil and gas to water treatment, our products are engineered to deliver reliability and performance in critical systems worldwide.

Description

Our comprehensive range of the products includes:

- Valve Bodies: Crafted from stainless steel, carbon steel, or specialized alloys to withstand high pressures and corrosive environments.

- Valve Stems: Precision-machined for smooth operation and long-term reliability in various valve types.

- Valve Seats: Engineered for perfect sealing, reducing leakage and improving efficiency.

- Ball Valves: Offering quick shut-off capabilities for critical flow control applications.

- Butterfly Valve Discs: Designed for optimal flow characteristics and durability.

- Gate Valve Components: Ensuring reliable shut-off in pipeline systems.

Each component is manufactured to tight tolerances, typically ±0.01mm, guaranteeing seamless integration and functionality in your valve assemblies.

| Material | 1) Aluminum: AL 6061-T6, 6063, 7075-T etc. |

| 2) Stainless steel: 303,304,316L, 17-4(SUS630) etc. | |

| 3) Steel: 4140, Q235, Q345B,20#,45# etc. | |

| 4) Titanium: TA1,TA2/GR2, TA4/GR5, TC4, TC18 etc. | |

| 5) Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc. | |

| 5) Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc. | |

| Finish | Sandblasting, Anodize color, Blackenning, Zinc/Nickl Plating, Polish. |

| Power coating, Passivation PVD, Titanium Plating, Electrogalvanizing. | |

| Electroplating chromium, electrophoresis, QPQ(Quench-Polish-Quench). | |

| Electro Polishing,Chrome Plating, Knurl, Laser etch Logo, etc | |

| Main Equipment | STEP,STP,GIS,CAD,PDF,DWG,DXF etc or samples. |

| Tolerance | +/-0.01mm ~ +/-0.05mm |

| Surface roughness | Ra 0.1~3.2 |

| Inspection | Complete inspection lab with Micrometer, Optical Comparator, Caliper Vernier,CMM. |

| Depth Caliper Vernier, Universal Protractor, Clock Gauge, Internal Centigrade Gauge | |

| Capacity | CNC turning work range: φ0.5mm-φ150mm*300mm. |

| CNC milling work range: 510mm*1020mm*500mm. |

Surface Treatment

To enhance performance and longevity, we offer various surface treatments for our products:

- Anodizing: For improved corrosion resistance on aluminum components

- Electroplating: Nickel or chrome plating for enhanced durability

- Sandblasting: Creating textured surfaces for better adhesion or aesthetics

- Brushing: Providing a sleek, uniform finish

Our experts can recommend the ideal surface treatment based on your specific application requirements.

Drawing Guide

We work closely with clients to bring their valve part designs to life. Our engineering team can assist with:

- CAD file interpretation and optimization

- Material selection for optimal performance

- Design for manufacturability (DFM) recommendations

- 3D modeling and prototyping services

Simply provide your technical drawings or specifications, and we'll guide you through the production process.

Production Process

Our state-of-the-art facility employs a rigorous production process:

- Material Sourcing: We use only high-quality, RoHS-compliant materials.

- CNC Machining: Utilizing advanced lathes and machining centers for precise cuts.

- Quality Control: In-process inspections ensure consistency throughout production.

- Surface Treatment: Application of specified finishes for enhanced performance.

- Final Inspection: Rigorous testing using 2.5D projectors and other advanced equipment.

- Packaging: Secure, custom packaging to protect parts during shipping.

Quality Certification

Junxion maintains strict quality control measures:

- ISO 9001:2015 certified quality management system

- Material traceability documentation

- Compliance with industry standards (ANSI, API, ASME)

- Detailed inspection reports and certificates of conformity

Shipping and Delivery

We understand the critical nature of valve parts in industrial operations. Our logistics capabilities include:

- Express sample delivery within 3 days

- Mass production orders shipped in 7-15 days

- Flexible shipping options (air, sea, or express courier)

- Real-time order tracking

- Customs documentation assistance for international shipments

Why Choose Us?

- Industry Expertise: Over a decade of experience in precision machining for critical industries.

- Customization: Tailored solutions to meet your exact specifications and application needs.

- Quality Assurance: Rigorous testing and inspection at every stage of production.

- Cost-Effective: Competitive pricing without compromising on quality.

- Responsive Service: Dedicated account managers and technical support.

FAQ

Q: What is your minimum order quantity (MOQ) for the products?

A: Our MOQs vary depending on the complexity of the part. We offer flexible options for both prototyping and mass production.

Q: Can you provide material certifications?

A: Yes, we provide full material traceability and certification upon request.

Q: Do you offer expedited production for urgent orders?

A: Absolutely. We can prioritize urgent orders to meet your deadlines. Contact us for rush order options.

Contact & Support

Ready to elevate your valve performance with precision-engineered valve parts? Contact our team today:

Email: Lock@junsion.com.cn, echo@junsion.com.cn, or evelyn@junsion.com.cn.

Let Dongguan Junsion Precision Hardware Co., Ltd. be your trusted partner for high-quality valve components. From prototyping to mass production, we're committed to delivering excellence in every part we manufacture.

_1755503925323.jpg)

_1755501421989.jpg)

_1755504107727.jpg)