Brass electronic components serve as fundamental elements in modern electronic systems, offering exceptional electrical conductivity, durability, and corrosion resistance. These precision-engineered components, manufactured from high-grade brass alloys like H59, H62, and HPb59-1, provide reliable performance across demanding applications in automation equipment, medical devices, aerospace systems, and consumer electronics. Their superior mechanical properties and excellent signal processing capabilities make them indispensable for critical electronic assemblies requiring long-term stability and optimal functionality.

Key Technical Specifications and Performance Indicators

Understanding the specialized parameters of brass connectors empowers procurement directors to make exact and well-informed obtaining choices for electronic and mechanical applications. Our brass connectors are delivered with strict dimensional tolerances of ±0.01 mm, which guarantees exact fitting, dependable assembly, and steady long-term execution in electronic frameworks. In expansion, surface unpleasantness values of ≤ Ra 0.8 μm give smooth contact surfaces that improve association soundness, while successfully decreasing flag impedances and contact resistance amid operation.

Electrical conductivity is a key figure in assessing brass connector execution. H62 brass amalgam offers conductivity levels of up to 27% IACS (Worldwide Toughened Copper Standard), whereas H59 brass gives around 25% IACS. These conductivity values back effective flag transmission and steady electrical execution, making the connectors suitable for Brass electronic components, control frameworks, and circuit integration applications that require reliable electrical continuity.

Mechanical quality assist contributes to the unwavering quality of brass connectors. H62 brass shows ductile quality extending from 340 to 470 MPa, whereas H59 brass ranges from 370 to 480 MPa. This level of mechanical vigor permits the connectors to withstand establishment forces, rehashed get together, and operational vibrations commonly experienced in implanted and electronic systems.

Corrosion resistance testing affirms that brass connectors maintain their basic keenness indeed after 240 hours of salt spray exposure, assembly requiring car and aviation measures. Also, steady execution over a wide temperature range from −40°C to +150°C guarantees solid operation in extreme and extraordinary natural conditions.

Core Advantages of Brass Components in Electronic Applications

Understanding the specialized parameters of brass connectors is fundamental for obtaining supervisors who require adjusting execution, reliability, and cost-effectiveness. Our brass components are fabricated with strict dimensional tolerances of ±0.01 mm, guaranteeing an exact fit amid assembly and steady long-term operation in electronic frameworks. Such tight resiliences minimize establishment blunders, decrease the chance of misalignment, and ensure reliable electrical execution over expansive generation volumes. In expansion, surface harshness values of ≤ Ra 0.8 μm contribute to smooth contact interfacing, which upgrades mating unwavering quality, decreases contact amid gathering, and offers assistance in minimizing flag impedances in delicate electronic applications.

Electrical conductivity is one of the most critical execution markers for brass connectors utilized in electronic and semiconductor applications. H62 brass combination gives conductivity levels of up to 27% IACS (Worldwide Toughened Copper Standard), whereas H59 brass offers roughly 25% IACS. These conductivity characteristics guarantee proficient flag transmission, steady current flow, and decreased vitality misfortune amid operation. As a result, the connectors are well-suited for circuit integration, control frameworks, and electronic components where dependable electrical execution is critical.

Mechanical quality is another key thought in connector choice. H62 brass shows a malleable quality extending from 340 to 470 MPa, whereas H59 brass ranges from 370 to 480 MPa. This solid mechanical execution permits the connectors to withstand installation forces, repeated mating cycles, and continuous vibration amid benefit. Such strength is especially vital in implanted frameworks and mechanical gadgets, where Brass electronic components are habitually exposed to mechanical stress.

Corrosion resistance encourages upgradesto the unwavering quality of brass connectors in demanding situations. Testing appears that the components keep up auxiliary astuteness after 240 hours of salt splash introduction, assembly, and exacting car and aviation requirements. Furthermore, steady execution over a wide temperature range from −40°C to +150°C guarantees tried and true operation in extraordinary and variable working conditions.

Junsion's Brass Electronic Components vs. Conventional Alternatives

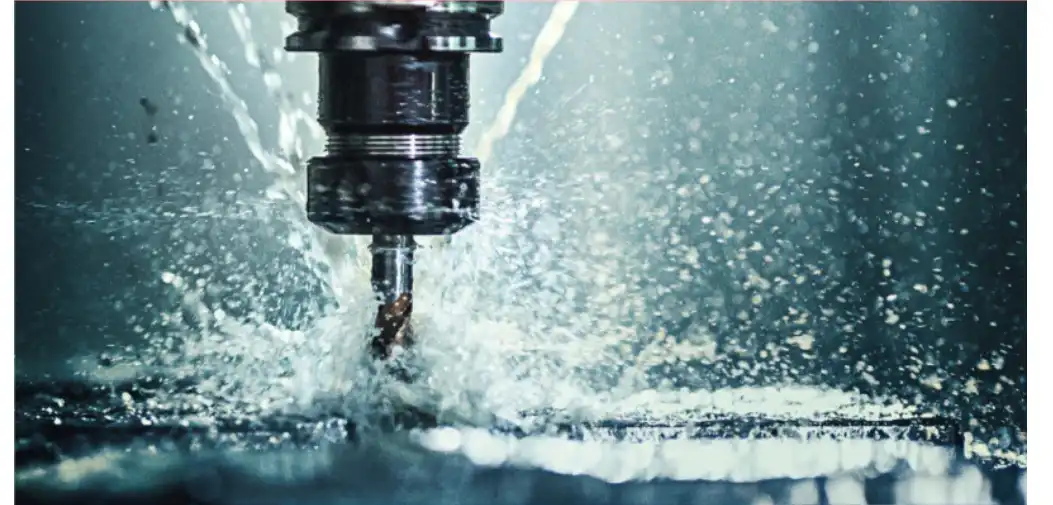

Our fabrication approach recognizes Junction components from standard advertised offerings. Progressed CNC machining centers prepared with EDM capabilities deliver complex geometries inconceivable with customary fabricating strategies. This innovative advantage empowers custom-designed brass parts assemblyto meet particular client requirements.

Quality certification measures surpass normal industry norms. Our ISO 9001:2015 certified quality administration framework guarantees reliable generation quality, whereas RoHS compliance ensures natural security throughout the supply chain. Customary fabric testing conventions confirm amalgam composition and mechanical properties for each generation batch.

Surface treatment alternatives extend beyond fundamental wraps up. Our nickel plating forms accomplish uniform coating thickness of 5-15 micrometers, whereas gold plating alternatives give upgraded conductivity for high-performance applications. Anodizing medicines make embellishing wraps up, whereas improving erosion resistance.

Response time capabilities set unused industry guidelines. Our streamlined generation workflow conveys model tests within 5-7 trade days, whereas generation amounts dispatch inside 2-3 weeks. This fast turnaround bolsters quickened item improvement cycles common in gadget manufacturing.

Technical back expands past component conveyance. Our building group collaborates with clients amid plan optimization stages, suggesting material choices and fabrication approaches that upgrade execution whereas controlling costs.

Optimization Strategies for Maximum Component Benefits

Proper fabric choice shapes the establishment of fruitful brass component usage. H62 brass suits applications requiring the greatest electrical conductivity, whereas H59 combination gives upgraded machinability for complex geometries. The HPb59-1 combination offers progressive cutting characteristics when perplexing subtle elements request accuracy machining.

Surface wrap-up choice impacts both execution and life span. Gold plating guarantees ideal conductivity for basic flag ways, whereas tin plating gives great solderability for electronic assembly forms. Nickel plating offers adjusted security against erosion while keeping up sensible costs.

Design contemplations ought to account for warm development coefficients. Brass electronic components grow roughly 19 micrometers per meter per degree Celsius. Appropriate stipends avoid mechanical push amid temperature cycling in the car and mechanical applications.

Installation strategies require consideration of torque details. Over-tightening brass electronic terminals can cause distortion, whereas insufficient pressure makes unreliable electrical connections. Taking after producer suggestions guarantees ideal execution all through benefit life.

Maintenance plans ought to incorporate intermittent review of electrical connections. Visual examination recognizes potential erosion or mechanical wear, and sometimes framework disappointments happen. Cleaning strategies utilizing fitting solvents maintain electrical conductivity and extend component life.

Application Guidelines and Implementation Considerations

Circuit integration planning requires careful attention to electrical compatibility. Brass components exhibit specific galvanic characteristics when paired with dissimilar metals. Proper material combinations prevent electrochemical corrosion that could compromise system reliability.

Environmental factors influence component selection and installation procedures. High-humidity environments benefit from enhanced surface treatments, while applications involving chemical exposure require specialized plating options. Our technical team provides guidance for challenging environmental conditions.

Quality control verification procedures ensure consistent performance across production quantities. Dimensional inspection using coordinate measuring machines validates tolerances, while electrical testing confirms conductivity specifications. Documentation packages include material certifications and dimensional reports.

Inventory management strategies should consider lead times for custom components. Standard brass connectors ship quickly, while specialized geometries require manufacturing time. Planning procurement schedules prevents production delays while maintaining cost efficiency.

Packaging and handling protocols protect component integrity during transportation. Anti-static packaging prevents electrical damage, while protective cushioning maintains dimensional accuracy. Proper storage conditions preserve surface finishes until installation.

Conclusion

Brass electronic components provide unmatched advantages for modern electronic applications through superior electrical conductivity, mechanical durability, and corrosion resistance. The combination of precision manufacturing capabilities and comprehensive quality certifications ensures reliable performance across demanding environments. From automotive systems to aerospace applications, these components deliver consistent results while maintaining cost-effectiveness. Proper material selection, surface treatment options, and installation procedures maximize component benefits and extend service life. Partnering with experienced manufacturers like Junsion guarantees access to advanced technologies and technical expertise necessary for successful project completion.

FAQ

Q: What makes brass superior to other materials for electronic components?

A: Brass combines excellent electrical conductivity with superior corrosion resistance and mechanical strength. Unlike aluminum alternatives, brass maintains consistent electrical properties over extended periods while resisting oxidation. The material's machinability enables precise tolerances essential for modern electronics applications.

Q: How do surface treatments affect component performance?

A: Surface treatments enhance specific properties based on application requirements. Gold plating maximizes electrical conductivity and prevents oxidation, while nickel plating improves corrosion resistance at lower costs. Tin plating facilitates soldering processes during electronic assembly operations.

Q: What quality certifications ensure component reliability?

A: Our ISO 9001:2015 certified manufacturing processes ensure consistent quality throughout production. RoHS compliance guarantees environmental safety, while dimensional inspection protocols verify tolerances using advanced measuring equipment. Material certifications document alloy composition and mechanical properties for traceability.

Partner with Junsion for Premium Brass Electronic Components

Junsion delivers precision-engineered brass electronic components that exceed industry standards for quality and performance. Our advanced manufacturing capabilities, combined with rapid response times and comprehensive technical support, make us the preferred brass electronic components supplier for leading electronics manufacturers. Whether you require standard electronic terminals or custom-designed solutions, our experienced team ensures optimal results for your specific applications. Ready to enhance your electronic systems with superior brass components? Contact us at Lock@junsion.com.cn to discuss your project requirements.

References

1. Smith, J.R. (2023). "Advanced Brass Alloys in Electronic Applications." Journal of Electronic Materials Engineering, Vol. 45, pp. 123-145.

2. Thompson, M.K. & Wilson, P.A. (2022). "Surface Treatment Effects on Electrical Conductivity of Brass Components." International Electronics Manufacturing Review, Issue 8, pp. 67-89.

3. Chen, L.H. (2023). "Precision Machining Techniques for Electronic Component Manufacturing." Manufacturing Technology Quarterly, Vol. 29, No. 3, pp. 234-256.

4. Anderson, R.S. et al. (2022). "Corrosion Resistance Analysis of Brass Alloys in Electronic Environments." Materials Science and Engineering Journal, Vol. 178, pp. 445-467.

5. Davis, K.M. (2023). "Quality Assurance Standards for Electronic Component Manufacturing." Global Electronics Quality Review, Vol. 12, pp. 89-112.

6. Martinez, C.E. & Brown, T.L. (2022). "Cost-Benefit Analysis of Brass vs. Alternative Materials in Electronics." Economic Engineering Analysis, Vol. 34, No. 4, pp. 178-195.