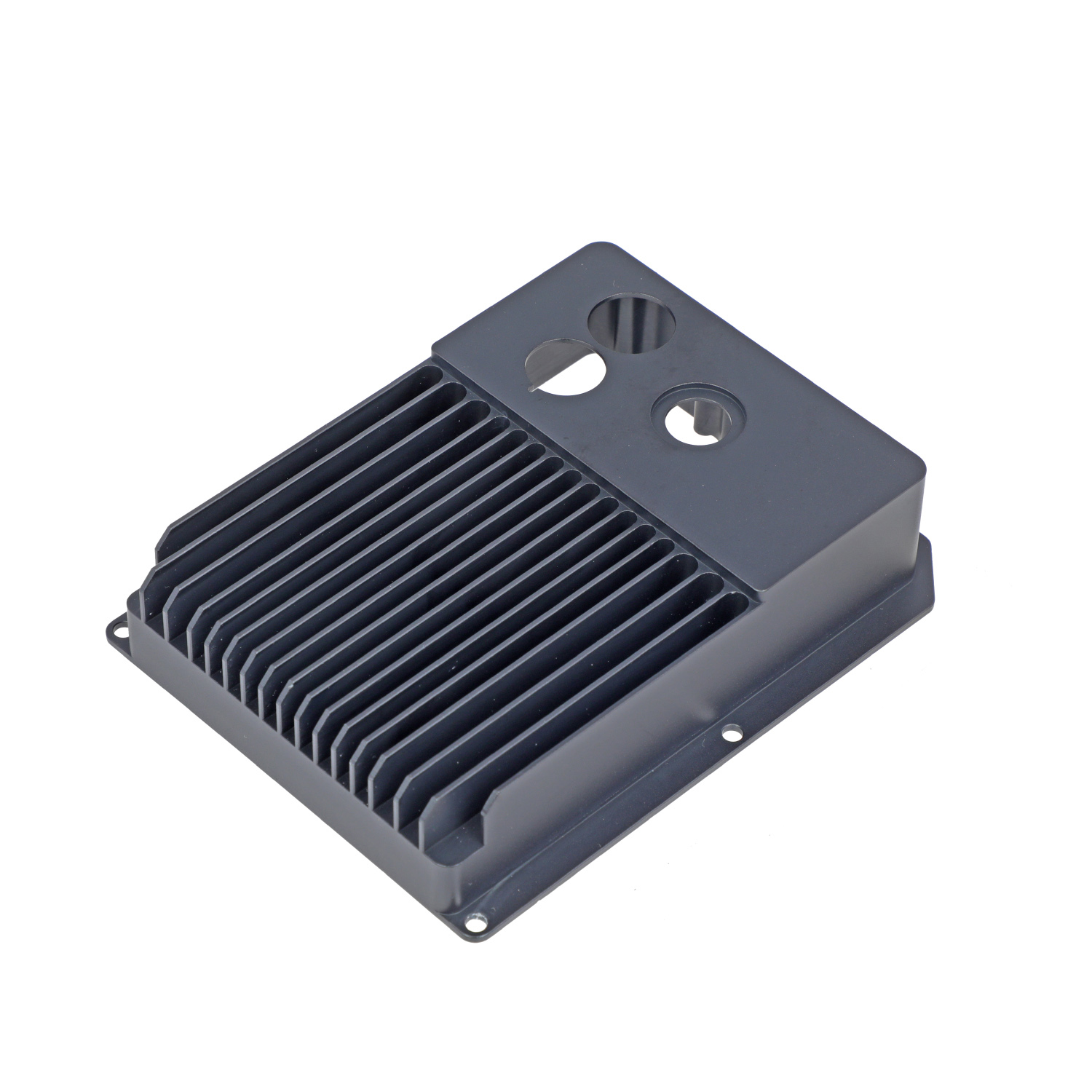

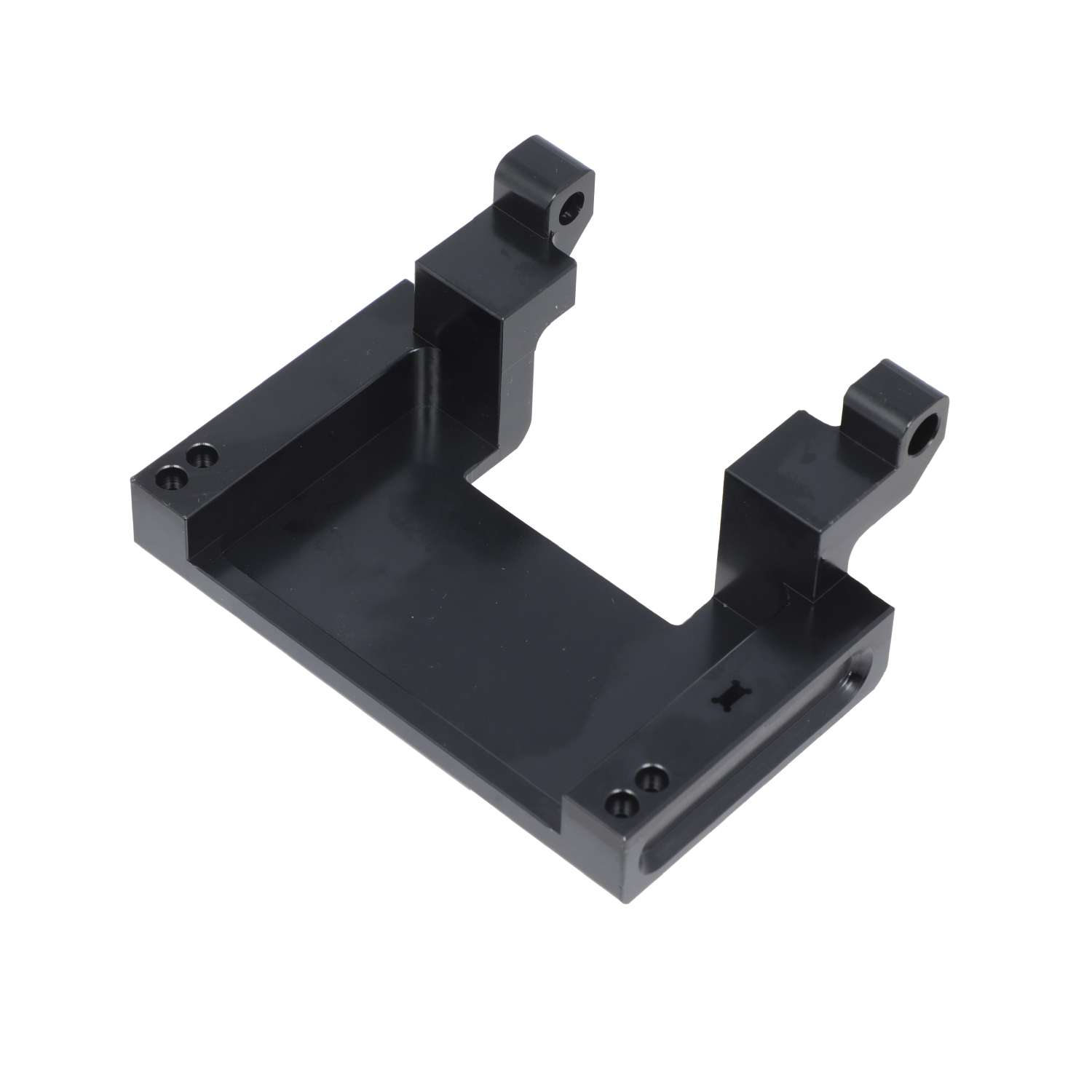

Pom Cover Parts

Material: pom

Processing techniques: CNC, turning, milling, cutting

Finish:anodizing,sandblasting, plating

Application fields: equipment,automotive,medical,home appliances

- Product Description

Pom Cover Parts: Precision-Engineered Solutions for Your Industrial Needs

At Dongguan Junsion Precision Hardware Co., Ltd., we specialize in manufacturing high-quality Pom Cover Parts. Our advanced CNC machining capabilities and strict quality control ensure that each Pom Cover Part meets the most exacting standards. With a wide range of customization options and quick turnaround times, we're your go-to supplier for precision Pom components.

Description

Our products are engineered for excellence. Made from high-grade polyoxymethylene (POM), these components offer:

- Exceptional dimensional stability

- Low friction and high wear resistance

- Excellent machinability

- Chemical resistance

- High strength-to-weight ratio

Whether you need products for automotive applications, consumer electronics, or industrial machinery, we've got you covered. Our parts are designed to withstand demanding environments and maintain their performance over time.

| Material | 1) Aluminum: AL 6061-T6, 6063, 7075-T etc. |

| 2) Stainless steel: 303,304,316L, 17-4(SUS630) etc. | |

| 3) Steel: 4140, Q235, Q345B,20#,45# etc. | |

| 4) Titanium: TA1,TA2/GR2, TA4/GR5, TC4, TC18 etc. | |

| 5) Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc. | |

| 5) Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc. | |

| Finish | Sandblasting, Anodize color, Blackenning, Zinc/Nickl Plating, Polish. |

| Power coating, Passivation PVD, Titanium Plating, Electrogalvanizing. | |

| Electroplating chromium, electrophoresis, QPQ(Quench-Polish-Quench). | |

| Electro Polishing,Chrome Plating, Knurl, Laser etch Logo, etc | |

| Main Equipment | STEP,STP,GIS,CAD,PDF,DWG,DXF etc or samples. |

| Tolerance | +/-0.01mm ~ +/-0.05mm |

| Surface roughness | Ra 0.1~3.2 |

| Inspection | Complete inspection lab with Micrometer, Optical Comparator, Caliper Vernier,CMM. |

| Depth Caliper Vernier, Universal Protractor, Clock Gauge, Internal Centigrade Gauge | |

| Capacity | CNC turning work range: φ0.5mm-φ150mm*300mm. |

| CNC milling work range: 510mm*1020mm*500mm. |

Surface Treatment

To enhance the properties of our products, we offer various surface treatments:

- Anodizing: Improves corrosion resistance and adds color

- Electroplating: Enhances conductivity and aesthetic appeal

- Sandblasting: Creates a matte finish for improved grip

- Brushing: Provides a sleek, professional look

Our expert team can recommend the best surface treatment based on your specific requirements.

Drawing Guide

We understand the importance of precision in your projects. That's why we offer a comprehensive drawing guide for our products. Our engineering team can work with your designs or help create custom solutions. We accept various file formats, including:

- 2D: DWG, DXF, PDF

- 3D: STEP, IGS, X_T

For optimal results, please include:

- Dimensional tolerances

- Material specifications

- Surface finish requirements

- Any special features or markings

Production Process

Our state-of-the-art facility ensures a seamless production process for your Pom Cover Parts:

- Material Selection: We source high-quality POM that meets your specifications.

- CNC Machining: Our precision CNC lathes and milling machines shape the parts with tolerances up to ±0.01mm.

- Quality Control: We perform rigorous in-process checks to maintain consistency.

- Surface Treatment: If required, we apply the specified surface finish.

- Final Inspection: Our quality assurance team conducts thorough checks before packaging.

Quality Certification

We're committed to delivering top-quality products. Our quality management system is ISO 9001:2015 certified, ensuring consistent quality across all our products. Additionally, we comply with RoHS and REACH standards, guaranteeing environmental safety.

Shipping and Delivery

We understand the importance of timely delivery in your supply chain. Our efficient logistics network allows us to offer:

- Sample delivery within 3 days

- Mass production orders within 7-15 days

- Flexible shipping options to meet your needs

We work with reliable shipping partners to ensure your products arrive safely and on time.

Why Choose JUNSION

- Industry Expertise: With over a decade of experience, we understand the nuances of the products manufacturing.

- Customization: We offer tailored solutions to meet your specific requirements.

- Quality Assurance: Our strict quality control processes ensure consistent, high-quality products.

- Competitive Pricing: Our efficient processes allow us to offer competitive rates without compromising on quality.

- Responsive Service: Our customer-centric approach means you'll always receive prompt, professional support.

FAQ

Q: What is the minimum order quantity for the products?

A: We offer flexible MOQs based on your needs. Contact us for a custom quote.

Q: Can you provide samples before mass production?

A: Absolutely! We offer sample services to ensure the parts meet your requirements.

Q: What industries do you typically serve?

A: We serve various industries, including automotive, electronics, medical devices, and industrial machinery.

Q: How do you ensure the quality of your products?

A: We use advanced testing equipment and follow strict quality control procedures throughout the production process.

Contact & Support

Ready to elevate your projects with our precision-engineered Pom Cover Parts? Our team is here to assist you every step of the way. Contact us today to discuss your requirements or request a quote.

Email: Lock@junsion.com.cn, echo@junsion.com.cn, or evelyn@junsion.com.cn.

Trust Dongguan Junsion Precision Hardware Co., Ltd. for all your products needs. Let's build something great together!

_1755669016530.jpg)

_1755502686263.jpg)