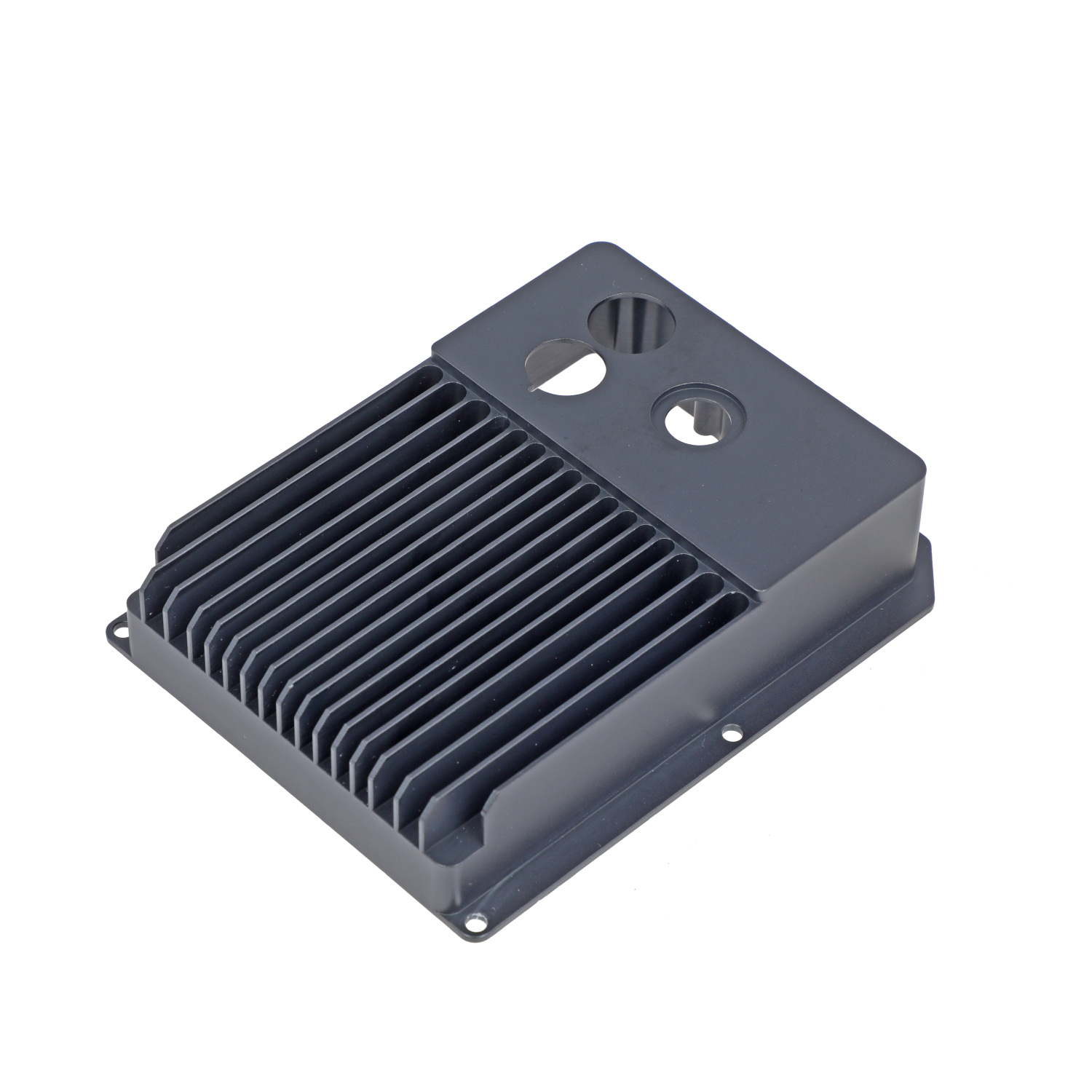

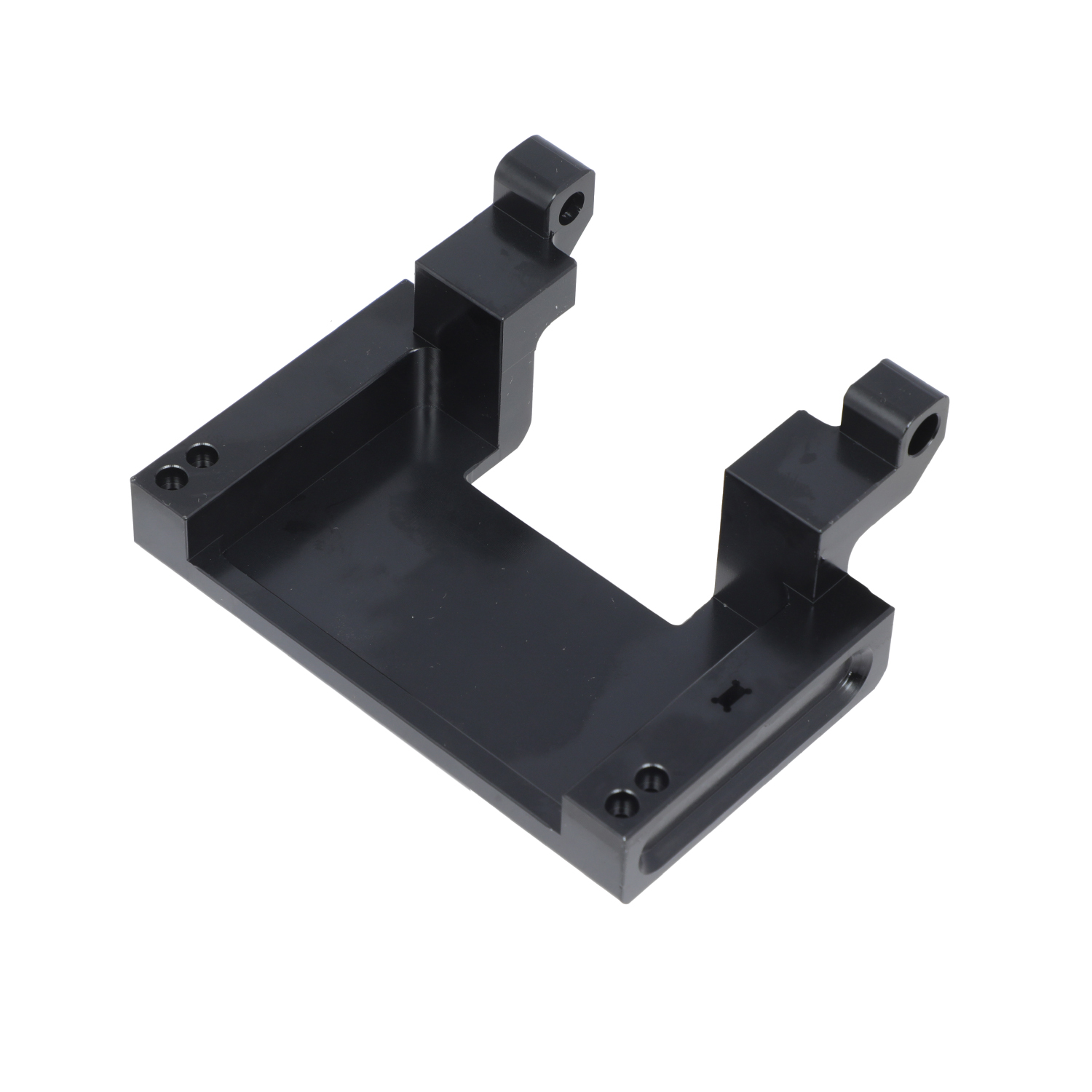

Customized Plastic Rack

Material: plastic

Processing techniques: CNC, turning,milling

Finish: painting, anodizing, QPQ ,wire drawing

Application fields: Automation equipment,automotive,medical,aerospace, AI Intelligent ,home appliances, robots, motorcycles etc.

- Product Description

Customized Plastic Racks: Durable Storage Solutions for Your Business

At Dongguan Junsion Precision Hardware Co., Ltd., we specialize in manufacturing high-quality customized plastic racks tailored to meet your specific storage needs. Our advanced precision machining capabilities and customer-centric approach ensure that you receive durable, efficient, and cost-effective storage solutions. With years of experience serving industries like manufacturing, logistics, and retail, we understand the importance of reliable storage systems in optimizing your operations.

Description

Our products are designed to provide versatile storage solutions for various industries. Made from high-grade, durable plastics, these racks offer:

- Exceptional strength-to-weight ratio

- Corrosion resistance

- Easy cleaning and maintenance

- Customizable dimensions and configurations

- Load capacities tailored to your needs

Whether you need small parts organizers for a production line or large-scale warehouse racking systems, our team can design and manufacture the perfect solution.

Specifications

Material | 1) Aluminum: AL 6061-T6, 6063, 7075-T etc. |

2) Stainless steel: 303,304,316L, 17-4(SUS630) etc. | |

3) Steel: 4140, Q235, Q345B,20#,45# etc. | |

4) Titanium: TA1,TA2/GR2, TA4/GR5, TC4, TC18 etc. | |

5) Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc. | |

5) Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc. | |

Finish | Sandblasting, Anodize color, Blackenning, Zinc/Nickl Plating, Polish. |

Power coating, Passivation PVD, Titanium Plating, Electrogalvanizing. | |

Electroplating chromium, electrophoresis, QPQ(Quench-Polish-Quench). | |

Electro Polishing,Chrome Plating, Knurl, Laser etch Logo, etc | |

Main Equipment | STEP,STP,GIS,CAD,PDF,DWG,DXF etc or samples. |

Tolerance | +/-0.01mm ~ +/-0.05mm |

Surface roughness | Ra 0.1~3.2 |

Inspection | Complete inspection lab with Micrometer, Optical Comparator, Caliper Vernier,CMM. |

Depth Caliper Vernier, Universal Protractor, Clock Gauge, Internal Centigrade Gauge | |

Capacity | CNC turning work range: φ0.5mm-φ150mm*300mm. |

CNC milling work range: 510mm*1020mm*500mm. |

Surface Treatment

To enhance the performance and aesthetics of your products, we offer various surface treatment options:

- Anti-static coatings for electronics industry applications

- UV-resistant treatments for outdoor use

- Antimicrobial finishes for medical or food storage

- Custom color options to match your branding

- Textured surfaces for improved grip and durability

Drawing Guide

Our engineering team works closely with you to develop precise drawings for your products. The process includes:

- Initial consultation to understand your requirements

- 3D modeling and prototyping

- Iterative design refinement based on your feedback

- Final approval of technical drawings

- Production-ready blueprints

This collaborative approach ensures that the final product meets your exact specifications and integrates seamlessly with your existing systems.

Production Process

Our state-of-the-art production facility employs advanced techniques to manufacture your customized plastic racks:

- Material selection based on your specific needs

- Precision injection molding or thermoforming

- CNC machining for intricate details and tight tolerances

- Assembly and quality control checks

- Surface treatment application

Quality Certification

At Junsion, we maintain strict quality control standards throughout the production process:

- ISO 9001:2015 certified quality management system

- RoHS compliance for environmental safety

- Regular material testing and batch inspections

- Dimensional accuracy checks using advanced measurement tools

- Load capacity testing to ensure safety and reliability

Shipping and Delivery

We understand the importance of timely delivery in your supply chain:

- Efficient production scheduling to meet your deadlines

- Careful packaging to prevent damage during transit

- Flexible shipping options (air, sea, or land freight)

- Real-time tracking information

- Customs documentation assistance for international orders

Why Choose Us?

- Expertise in product manufacturing

- Cutting-edge production facilities and technologies

- Commitment to quality and customer satisfaction

- Competitive pricing for bulk orders

- Responsive customer support and after-sales service

FAQ

Q: What is the minimum order quantity for the products?

A: Our MOQ varies depending on the complexity of the design. We're flexible and can discuss options to meet your needs.

Q: Can you provide samples before full production?

A: Yes, we offer prototyping services to ensure the final product meets your expectations.

Q: What is the lead time for the products?

A: Lead times vary based on order volume and complexity. Typically, we can deliver within 15-30 days after design approval.

Q: Do you offer warranty on your products?

A: Yes, we provide a warranty against manufacturing defects. The specific terms depend on the product and usage conditions.

Q: Can you help with the design process if we don't have exact specifications?

A: Absolutely. Our engineering team can work with you to develop the perfect solution based on your requirements.

Contact & Support

Ready to optimize your storage with customized plastic racks? Contact our team today:

Email: Lock@junsion.com.cn, echo@junsion.com.cn, or evelyn@junsion.com.cn.

Let Dongguan Junsion Precision Hardware Co., Ltd. be your trusted partner in creating efficient, durable, and tailored storage solutions for your business.

_1755669016530.jpg)