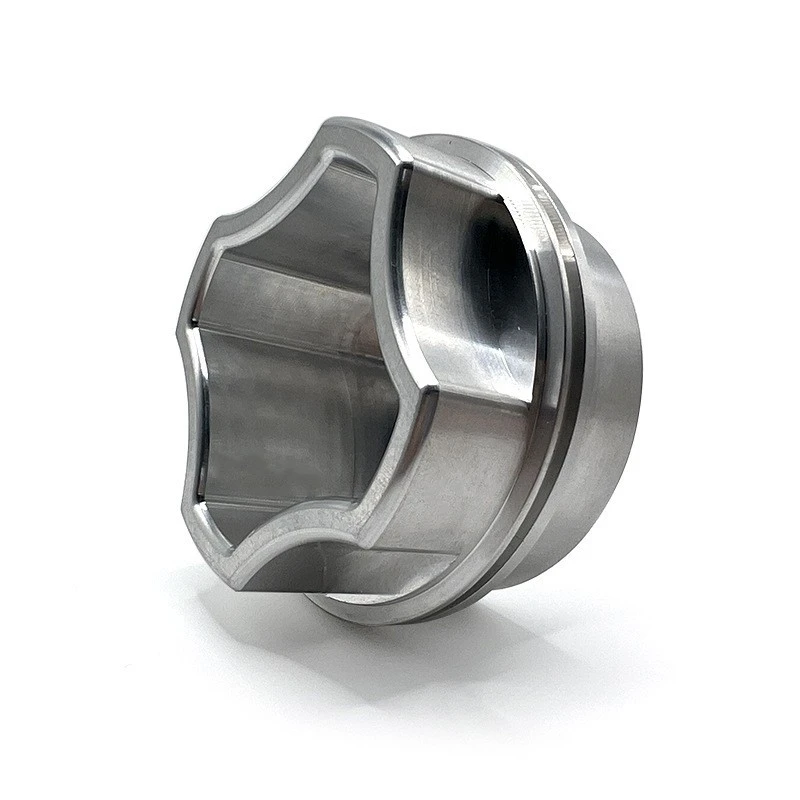

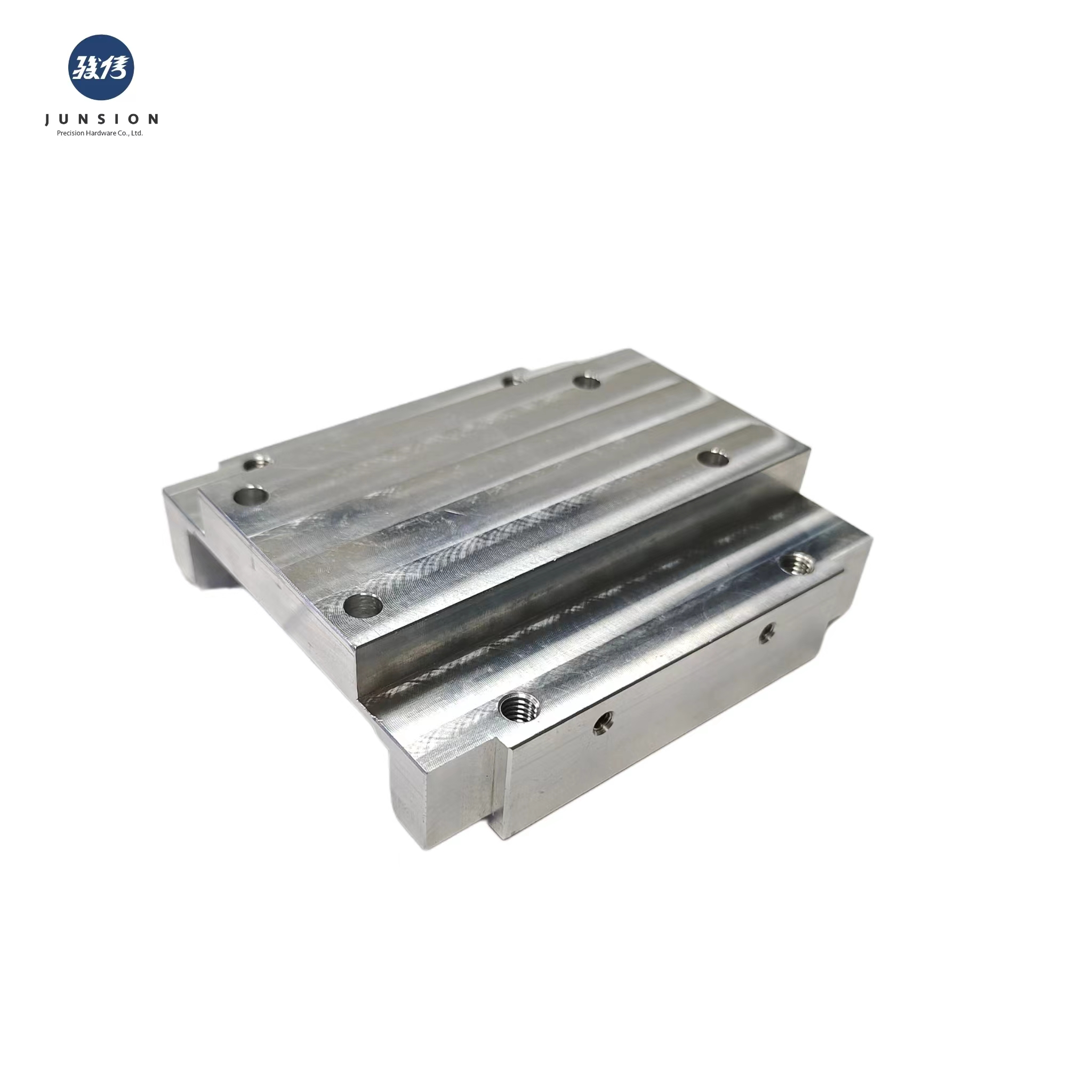

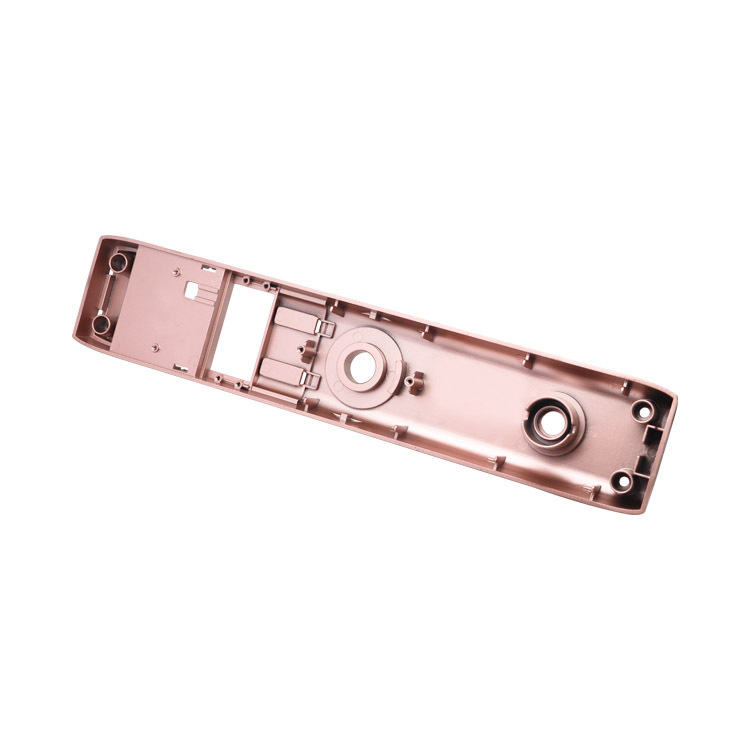

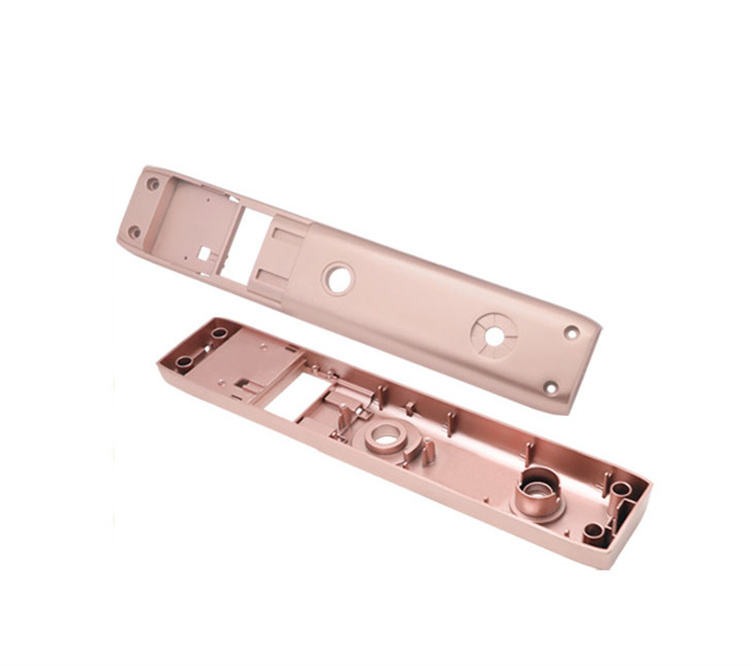

Stainless Steel Stamping Parts

Material: 316/304/303/410 stainless steel

Processing techniques: stamping

Finish:Polishing, painting, anodizing,sandblasting, plating ,blackening, electrophoresis, QPQ ,wire drawing

Application fields: Automation equipment,Vehicle,medical,aerospace, AI Intelligent ,home appliances, robots,

- Product Description

Stainless Steel Stamping Parts: Precision Solutions for Your Manufacturing Needs

At Dongguan Junsion Precision Hardware Co., Ltd., we specialize in manufacturing high-quality stainless steel stamping parts. Our cutting-edge machinery and sophisticated precision machining skills guarantee that we supply parts with tolerances as low as ±0.01mm. As a top supplier, we provide specialized solutions that are matched to your unique needs and supported by our wealth of industry knowledge and dedication to quality.

Description

Our products are the perfect choice for industries demanding durability, corrosion resistance, and precision. We utilize premium-grade stainless steel, including popular options like 304 and 316, to create components that withstand harsh environments and maintain their integrity over time.

| Material | 1) Aluminum: AL 6061-T6, 6063, 7075-T etc. |

| 2) Stainless steel: 303,304,316L, 17-4(SUS630) etc. | |

| 3) Steel: 4140, Q235, Q345B,20#,45# etc. | |

| 4) Titanium: TA1,TA2/GR2, TA4/GR5, TC4, TC18 etc. | |

| 5) Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc. | |

| 5) Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc. | |

| Finish | Sandblasting, Anodize color, Blackenning, Zinc/Nickl Plating, Polish. |

| Power coating, Passivation PVD, Titanium Plating, Electrogalvanizing. | |

| Electroplating chromium, electrophoresis, QPQ(Quench-Polish-Quench). | |

| Electro Polishing,Chrome Plating, Knurl, Laser etch Logo, etc | |

| Main Equipment | STEP,STP,GIS,CAD,PDF,DWG,DXF etc or samples. |

| Tolerance | +/-0.01mm ~ +/-0.05mm |

| Surface roughness | Ra 0.1~3.2 |

| Inspection | Complete inspection lab with Micrometer, Optical Comparator, Caliper Vernier,CMM. |

| Depth Caliper Vernier, Universal Protractor, Clock Gauge, Internal Centigrade Gauge | |

| Capacity | CNC turning work range: φ0.5mm-φ150mm*300mm. |

| CNC milling work range: 510mm*1020mm*500mm. |

Key Features

- Excellent corrosion resistance

- High strength-to-weight ratio

- Versatile applications across industries

- Customizable designs to meet your specifications

- Tight tolerances for optimal performance

Common Applications

- Automotive components

- Aerospace parts

- Electronics housings

- Medical device components

- Industrial machinery parts

Surface Treatment

To enhance the performance and aesthetics of your products, we offer a range of surface treatments:

- Passivation: Improves corrosion resistance by creating a protective oxide layer.

- Electropolishing: Smooths surfaces and increases shine for a polished finish.

- Anodizing: Adds color and improves wear resistance (for aluminum parts).

- Powder coating: Provides a durable, colorful finish for enhanced aesthetics.

- Plating: Offers additional protection and decorative options (e.g., nickel, chrome).

StAInless Teel Stamping Parts Drawing Guide

To ensure accurate production of your stainless steel stamping parts, please provide:

- Detailed 2D or 3D CAD drawings

- Material specifications (e.g., grade of stainless steel)

- Tolerance requirements

- Surface finish preferences

- Quantity needed

- Any special features or secondary operations required

Our engineering team is available to assist with design optimization and material selection to maximize performance and cost-effectiveness.

Production Process

- Material Selection: Choose the appropriate grade of stainless steel.

- Die Design: Create custom tooling based on your specifications.

- Stamping: Use precision presses to form the parts.

- Trimming: Remove excess material for clean edges.

- Secondary Operations: Perform additional processes as needed (e.g., bending, welding).

- Surface Treatment: Apply specified finishes.

- Quality Control: Conduct rigorous inspections throughout production.

- Packaging: Carefully package parts to prevent damage during shipping.

Quality Certification

We maintain strict quality control measures to ensure that every product meets or exceeds industry standards:

- ISO 9001:2015 certified quality management system

- RoHS compliance for environmental safety

- Material certifications and test reports available upon request

- In-process quality checks and final inspections using advanced testing equipment

Shipping and Delivery

We understand the importance of timely delivery in your supply chain:

- Fast turnaround times: Samples within 3 days, mass production in 7-15 days

- Global shipping capabilities with reliable logistics partners

- Flexible packaging options to suit your needs

- Real-time order tracking for peace of mind

Why Choose Us?

- One-stop custom solutions from prototyping to mass production

- Advanced precision machining capabilities for consistent accuracy

- Wide material selection and stable quality assurance

- Extensive industry experience serving 500+ satisfied global clients

- Customer-centric approach with responsive communication

- Competitive pricing and flexible MOQ options

FAQ

Q: What is the minimum order quantity (MOQ) for the products?

A: Our MOQ varies depending on the complexity and size of the part. Contact us for a customized quote.

Q: Can you provide samples before mass production?

A: Yes, we offer prototyping services and can provide samples for approval before full-scale production.

Q: What industries do you serve with your products?

A: Automotive, aerospace, electronics, medical, and industrial equipment manufacture are just a few of the industries we serve.

Q: How do you ensure the quality of your products?

A: Throughout the production process, we employ stringent quality control procedures, such as material inspections, in-process checks, and testing of the finished product.

Contact & Support

Ready to elevate your manufacturing with precision stainless steel stamping parts? Contact our expert team today for personalized support and quotes:

Email: Lock@junsion.com.cn, echo@junsion.com.cn, or evelyn@junsion.com.cn.

Trust Dongguan Junsion Precision Hardware Co., Ltd. for all your products needs. Let's build a lasting partnership that drives your success through quality, precision, and reliability.

_1755503569793.jpg)

_1755501595589.jpg)