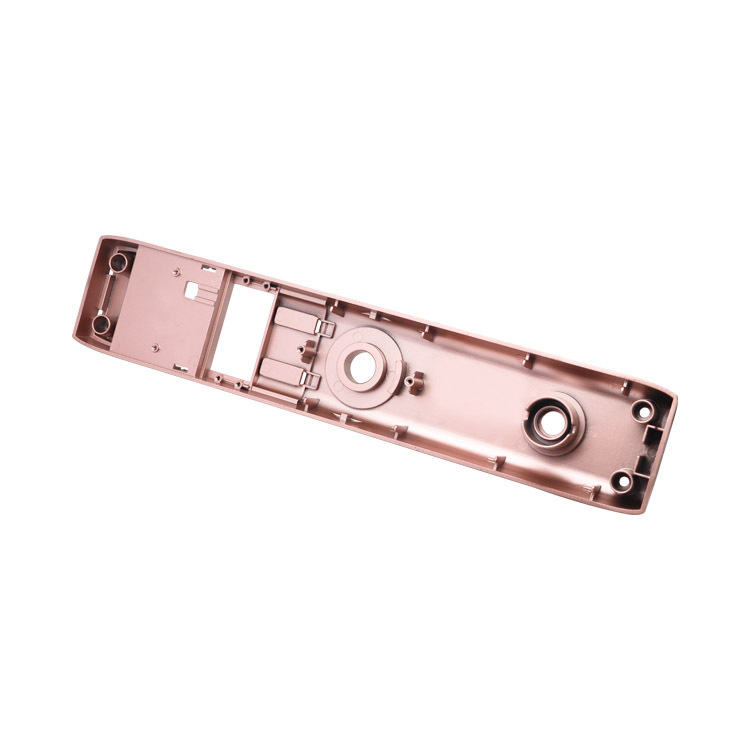

Metal Shaft Part

Material: 316/304/303/410 stainless steel

Processing techniques: CNC, turning, five axis machining, stamping

Finish:Polishing, painting, anodizing,sandblasting, plating , electrophoresis

Application fields: Automation equipment,Vehicle,medical,aerospace, AI Intelligent ,home appliances, robots,

- Product Description

Metal Shaft Parts: Precision-Engineered Solutions for Industrial Applications

At Dongguan Junsion Precision Hardware Co., Ltd., we specialize in manufacturing high-quality Metal Shaft Parts for various industries. We are a top supplier of custom metal parts because we are dedicated to excellence and have advanced precision machining capabilities. We make sure that the products we send you are reliable and accurate, with tolerances of up to ±0.01mm. They meet the strictest requirements.

Description

Our products are important parts of many mechanical systems. They provide important support and motion transfer in automobile and industrial machinery, among other places. These precision-engineered parts are made to hold up under heavy loads, keep their shape, and not wear out under a wide range of operating situations.

| Material | 1) Aluminum: AL 6061-T6, 6063, 7075-T etc. |

| 2) Stainless steel: 303,304,316L, 17-4(SUS630) etc. | |

| 3) Steel: 4140, Q235, Q345B,20#,45# etc. | |

| 4) Titanium: TA1,TA2/GR2, TA4/GR5, TC4, TC18 etc. | |

| 5) Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc. | |

| 5) Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc. | |

| Finish | Sandblasting, Anodize color, Blackenning, Zinc/Nickl Plating, Polish. |

| Power coating, Passivation PVD, Titanium Plating, Electrogalvanizing. | |

| Electroplating chromium, electrophoresis, QPQ(Quench-Polish-Quench). | |

| Electro Polishing,Chrome Plating, Knurl, Laser etch Logo, etc | |

| Main Equipment | STEP,STP,GIS,CAD,PDF,DWG,DXF etc or samples. |

| Tolerance | +/-0.01mm ~ +/-0.05mm |

| Surface roughness | Ra 0.1~3.2 |

| Inspection | Complete inspection lab with Micrometer, Optical Comparator, Caliper Vernier,CMM. |

| Depth Caliper Vernier, Universal Protractor, Clock Gauge, Internal Centigrade Gauge | |

| Capacity | CNC turning work range: φ0.5mm-φ150mm*300mm. |

| CNC milling work range: 510mm*1020mm*500mm. |

Key Features

- High precision tolerances

- Excellent surface finish

- Superior material strength

- Customizable designs

- Consistent quality across large production runs

We offer a wide range of materials for our shaft parts, including:

- Stainless Steel (303, 304, 316)

- Carbon Steel

- Aluminum Alloys

- Brass

- Titanium

Our engineering team works closely with clients to select the optimal material based on specific application requirements, ensuring peak performance and longevity.

Surface Treatment

To enhance the performance and durability of our products, we offer various surface treatment options:

- Anodizing (for aluminum parts)

- Electroplating (chrome, nickel, zinc)

- Black oxide coating

- Phosphating

- Heat treatment (case hardening, tempering)

These treatments improve corrosion resistance, wear resistance, and aesthetic appeal, tailoring the parts to your exact specifications.

Drawing Guide

For custom Metal Shaft Parts, we recommend providing detailed technical drawings that include:

- Dimensions and tolerances

- Material specifications

- Surface finish requirements

- Heat treatment or coating specifications

- Critical features or special notes

Our team of experts can assist in optimizing designs for manufacturability and cost-effectiveness.

Production Process

Our state-of-the-art facility employs a rigorous production process to ensure consistent quality:

- Material selection and inspection

- CNC turning or milling

- In-process quality checks

- Heat treatment (if required)

- Surface finishing

- Final inspection and testing

- Packaging and shipping

We use modern CNC machines and accurate measuring tools throughout the whole process to make sure that it is accurate and can be done again and again.

Quality Certification

Junxion is dedicated to upholding the highest levels of quality. Our quality management system is approved to ISO 9001:2015, which means that the quality of our products will always be the same and our customers will be happy. We also follow standards that are specific to our business, like IATF 16949 for automotive parts when they are needed.

Shipping and Delivery

We understand the importance of timely delivery in today's fast-paced manufacturing environment. Our efficient production scheduling and reliable logistics network enable us to offer:

- Sample delivery within 3 days

- Mass production orders within 7-15 days

- Flexible shipping options to meet your specific needs

Why Choose Us?

- Advanced precision machining capabilities

- Customizable solutions for unique requirements

- Wide range of materials and surface treatments

- Strict quality control measures

- Fast turnaround times

- Extensive industry experience

- Global reach with satisfied clients worldwide

Our customer-centric approach and commitment to excellence make us your ideal partner for long-term metal parts manufacturing cooperation.

FAQ

Q1: What is the minimum order quantity (MOQ) for the products?

A1: Our MOQ varies depending on the complexity and specifications of the part. Please contact us for a customized quote.

Q2: Can you provide prototypes before mass production?

A2: Yes, we offer prototyping services to ensure the design meets your requirements before proceeding to full production.

Q3: What quality control measures do you have in place?

A3: We implement a comprehensive quality control system, including IQC, IPQC, and OQC, using advanced testing equipment to ensure every product meets international standards.

Q4: Do you offer design assistance for the products?

A4: Absolutely. Our engineering team can provide support in material selection, structural optimization, and design for manufacturability.

Q5: What industries do you serve with your the products?

A5: Our products are used in many areas, such as consumer electronics, medical equipment, automobiles, and industrial machinery.

Contact & Support

Ready to elevate your products with our precision-engineered Metal Shaft Parts? Get in touch with our team of experts right away for personalised help and quotes. The best parts and the best service are what we're committed to giving you.

Email: Lock@junsion.com.cn, echo@junsion.com.cn, or evelyn@junsion.com.cn.

Trust Junxion for all your product needs – where precision meets performance.

_1755501421989.jpg)

_1755501595589.jpg)

_1755504107727.jpg)