Threaded Insert

Material: 316/304/303/410 stainless steel

Processing techniques: CNC, turning, five axis machining, stamping

Finish:Polishing, painting, anodizing,sandblasting, plating , electrophoresis

Application fields: Automation equipment,Vehicle,medical,aerospace, AI Intelligent ,home appliances, robots,

- Product Description

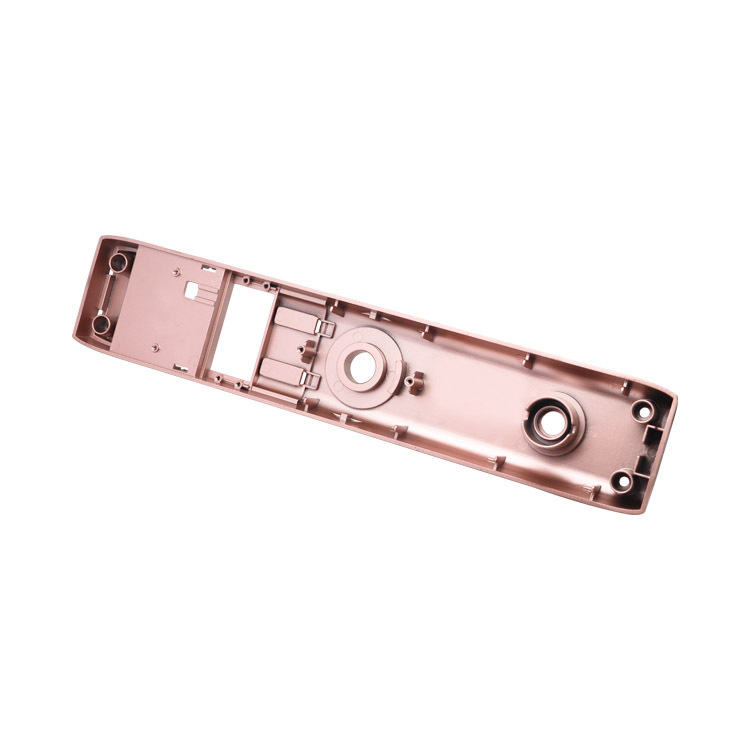

Threaded Inserts: Precision Fastening Solutions by Junsion

At Dongguan Junsion Precision Hardware Co., Ltd., we specialize in manufacturing high-quality threaded inserts for various industries. Because we are dedicated to quality and can do advanced precision machining, you can trust us to provide you with fastening solutions. With tolerances as small as ±0.01mm, Junsion's products are the most accurate and reliable you can find for your toughest jobs.

_1755505276143.jpg)

Description

Our products are cylinder-shaped fasteners made to make strong threads in plastics, wood, and light metals that don't wear down easily. For different efficiency and environmental needs, our inserts come in different materials, such as stainless steel, brass, and aluminium.

| Material | 1) Aluminum: AL 6061-T6, 6063, 7075-T etc. |

| 2) Stainless steel: 303,304,316L, 17-4(SUS630) etc. | |

| 3) Steel: 4140, Q235, Q345B,20#,45# etc. | |

| 4) Titanium: TA1,TA2/GR2, TA4/GR5, TC4, TC18 etc. | |

| 5) Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc. | |

| 5) Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc. | |

| Finish | Sandblasting, Anodize color, Blackenning, Zinc/Nickl Plating, Polish. |

| Power coating, Passivation PVD, Titanium Plating, Electrogalvanizing. | |

| Electroplating chromium, electrophoresis, QPQ(Quench-Polish-Quench). | |

| Electro Polishing,Chrome Plating, Knurl, Laser etch Logo, etc | |

| Main Equipment | STEP,STP,GIS,CAD,PDF,DWG,DXF etc or samples. |

| Tolerance | +/-0.01mm ~ +/-0.05mm |

| Surface roughness | Ra 0.1~3.2 |

| Inspection | Complete inspection lab with Micrometer, Optical Comparator, Caliper Vernier,CMM. |

| Depth Caliper Vernier, Universal Protractor, Clock Gauge, Internal Centigrade Gauge | |

| Capacity | CNC turning work range: φ0.5mm-φ150mm*300mm. |

| CNC milling work range: 510mm*1020mm*500mm. |

Key Features

- Precise internal and external threading

- Multiple installation methods (press-fit, heat-set, or ultrasonic)

- Corrosion resistance options

- Custom sizes and thread patterns available

- Compatible with a wide range of host materials

Surface Treatment

We offer various surface treatments to enhance the performance and appearance of our products:

- Anodizing (for aluminum inserts)

- Electroplating (zinc, nickel, or chrome)

- Passivation (for stainless steel)

- Dry film lubrication

These treatments improve corrosion resistance, reduce friction, and can provide color-coding options for easy identification.

Drawing Guide

Our engineering team provides comprehensive support for your threaded insert projects:

- CAD files and 3D models available upon request

- Detailed technical drawings with critical dimensions

- Material specifications and mechanical properties

- Installation guidelines and torque recommendations

We work closely with your design team to ensure our inserts meet your exact specifications and performance requirements.

Production Process

Junsion's state-of-the-art manufacturing process ensures consistent quality:

- Material selection and testing

- CNC machining of insert body

- Thread cutting or rolling

- Surface treatment application

- Dimensional inspection and quality control

- Packaging and labeling

Our efficient production scheduling allows for quick turnaround times, with samples available in as little as 3 days and mass production orders completed within 7-15 days.

Quality Certification

Junsion is committed to maintaining the highest quality standards:

- ISO 9001:2015 certified quality management system

- RoHS compliant materials

- Rigorous incoming material inspection (IQC)

- In-process quality control (IPQC)

- Final outgoing quality check (OQC)

We use advanced testing equipment, including 2.5D projectors and hardness testers, to ensure every product meets or exceeds industry standards.

Shipping and Delivery

Our reliable logistics network ensures your products arrive on time:

- Global shipping capabilities

- Flexible packaging options (bulk or individual)

- Track and trace services available

- Express shipping for urgent orders

- Inventory management solutions for high-volume customers

Why Choose Us?

- Advanced precision machining capabilities

- Customization options to meet your specific needs

- Wide material selection and stable quality

- Fast turnaround times

- Strict quality control system

- Extensive industry experience and global reach

- Customer-centric service approach

Our products are trusted by over 500 satisfied clients in industries such as automotive, aerospace, electronics, and industrial automation.

FAQ

Q: What is the minimum order quantity for custom products?

A: Our MOQ varies depending on the complexity of the design. Contact us for a quote on your specific requirements.

Q: Can you provide samples before mass production?

A: Yes, we offer sample production services to ensure the inserts meet your specifications before proceeding with larger orders.

Q: What materials are available for the products?

A: We offer stainless steel, brass, aluminum, and other materials upon request. All our materials are RoHS compliant.

Q: How long does it take to receive a quote?

A: We typically provide quotes within 24-48 hours of receiving your inquiry and specifications.

Contact & Support

Ready to enhance your fastening solutions with Junsion's precision threaded inserts? Our team is here to assist you:

- Email: Lock@junsion.com.cn, echo@junsion.com.cn, or evelyn@junsion.com.cn.

Contact us today for expert advice, custom quotations, or to discuss your specific productt requirements. Trust Junsion to deliver the quality, precision, and service your projects demand.

_1755505276143.jpg)

_1755501421989.jpg)