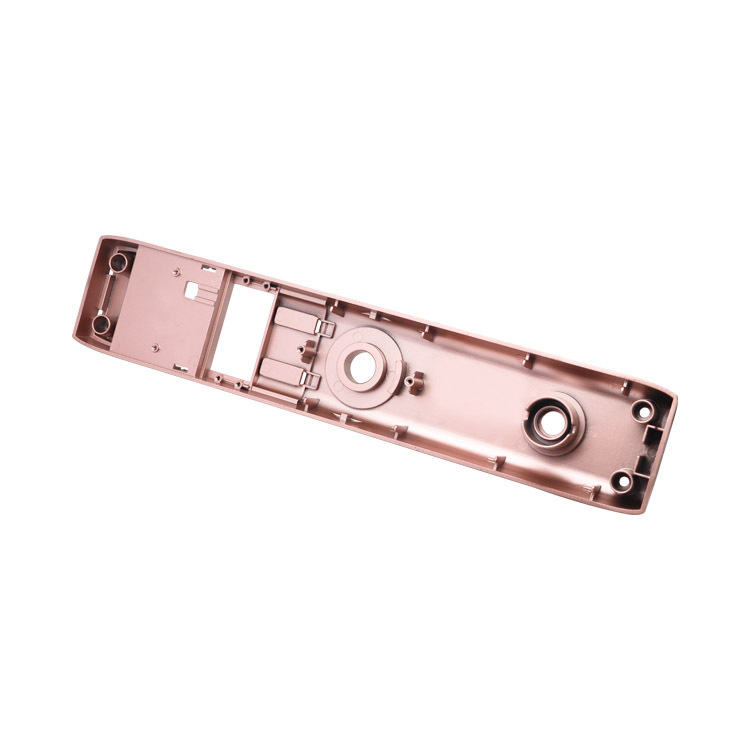

CNC Machining Stainless Steel Parts

Material: 45 steel

Processing techniques: stamping

Finish:Polishing, painting, anodizing,sandblasting, plating ,blackening, electrophoresis, QPQ ,wire drawing

Application fields: Automation equipment,Vehicle,medical,aerospace, AI Intelligent ,home appliances, robots,

- Product Description

CNC Machining Stainless Steel Parts: Precision Solutions for Industry Leaders

Dongguan Junsion Precision Hardware Co., Ltd. is your premier manufacturer and supplier of high-quality CNC machining stainless steel parts. With our advanced precision machining capabilities and state-of-the-art equipment, we deliver exceptional components that meet the most demanding specifications. Our products are renowned for their unparalleled accuracy, durability, and superior finish, making us the go-to choice for industry leaders worldwide.

Description

At Junsion, we specialize in producing top-tier products tailored to your unique requirements. Our extensive range includes:

- Custom Fasteners: Precision-engineered bolts, screws, and nuts

- Automotive Components: Durable engine parts, chassis components, and more

- Medical Device Parts: High-precision instruments and implant components

- Aerospace Hardware: Lightweight yet robust structural elements

- Industrial Machinery Parts: Wear-resistant gears, shafts, and fittings

We work with various stainless steel grades, including 304, 316, 17-4PH, and 420, ensuring the perfect material for your application. Our advanced CNC machines can achieve tolerances as tight as ±0.01mm, guaranteeing consistent quality across large production runs.

| Material | 1) Aluminum: AL 6061-T6, 6063, 7075-T etc. |

| 2) Stainless steel: 303,304,316L, 17-4(SUS630) etc. | |

| 3) Steel: 4140, Q235, Q345B,20#,45# etc. | |

| 4) Titanium: TA1,TA2/GR2, TA4/GR5, TC4, TC18 etc. | |

| 5) Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc. | |

| 5) Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc. | |

| Finish | Sandblasting, Anodize color, Blackenning, Zinc/Nickl Plating, Polish. |

| Power coating, Passivation PVD, Titanium Plating, Electrogalvanizing. | |

| Electroplating chromium, electrophoresis, QPQ(Quench-Polish-Quench). | |

| Electro Polishing,Chrome Plating, Knurl, Laser etch Logo, etc | |

| Main Equipment | STEP,STP,GIS,CAD,PDF,DWG,DXF etc or samples. |

| Tolerance | +/-0.01mm ~ +/-0.05mm |

| Surface roughness | Ra 0.1~3.2 |

| Inspection | Complete inspection lab with Micrometer, Optical Comparator, Caliper Vernier,CMM. |

| Depth Caliper Vernier, Universal Protractor, Clock Gauge, Internal Centigrade Gauge | |

| Capacity | CNC turning work range: φ0.5mm-φ150mm*300mm. |

| CNC milling work range: 510mm*1020mm*500mm. |

Surface Treatment

To enhance performance and aesthetics, we offer a wide range of surface treatments for our products:

- Anodizing: Improves corrosion resistance and creates decorative finishes

- Electroplating: Enhances hardness and wear resistance

- Passivation: Increases corrosion resistance by removing free iron from the surface

- Sandblasting: Creates a uniform matte finish

- Polishing: Achieves mirror-like surfaces for aesthetic or functional purposes

Our engineering team can recommend the ideal surface treatment based on your part's intended use and environment.

Drawing Guide

To ensure we meet your exact specifications, we recommend providing:

- 2D or 3D CAD files (preferred formats: STEP, IGES, or DWG)

- Detailed technical drawings with dimensions and tolerances

- Material specifications and grade requirements

- Surface finish and treatment preferences

- Quantity and delivery timeline

Our experienced engineers will review your drawings and provide feedback or suggestions for optimizing manufacturability and cost-efficiency.

Production Process

Our streamlined production process for the products includes:

- Design Review & Optimization

- Material Selection & Procurement

- CNC Programming & Setup

- Precision Machining

- In-Process Quality Control

- Surface Treatment (if required)

- Final Inspection & Testing

- Packaging & Shipping

Throughout each stage, our skilled technicians maintain strict quality control measures to ensure your parts meet or exceed your expectations.

Quality Certification

Junsion is committed to delivering the highest quality CNC machining stainless steel parts. Our quality management system is certified to:

- ISO 9001:2015

- IATF 16949 (for automotive components)

- AS9100D (for aerospace parts)

We also comply with RoHS and REACH standards, ensuring our products are environmentally friendly and safe for use in various industries.

Shipping and Delivery

We understand the importance of timely delivery in today's fast-paced manufacturing environment. Our efficient production scheduling and reliable logistics network enable us to offer:

- Sample delivery within 3 days

- Mass production orders within 7-15 days

We ship worldwide and can accommodate various transportation methods to meet your specific needs and timelines.

Why Choose Us?

- Advanced Precision Machining: State-of-the-art equipment for unmatched accuracy

- One-Stop Custom Solutions: From prototyping to mass production

- Wide Material Selection: Variety of stainless steel grades and surface treatments

- Fast Turnaround Time: Quick delivery to support your production schedules

- Strict Quality Control: Comprehensive testing and inspection at every stage

- Industry Experience: Trusted by 500+ clients across diverse sectors

- Customer-Centric Service: Transparent communication and responsive support

FAQ

Q: What is the minimum order quantity for the products?

A: We offer flexible order quantities, from prototypes to large production runs. Contact us for specific requirements.

Q: Can you provide material certifications?

A: Yes, we provide material certifications and test reports upon request.

Q: Do you offer design assistance for the products?

A: Our engineering team can provide design optimization suggestions to improve manufacturability and reduce costs.

Q: What industries do you serve?

A: We serve various industries, including automotive, aerospace, medical, industrial machinery, and consumer electronics.

Contact & Support

Ready to elevate your production with our premium CNC machining stainless steel parts? Contact our expert team today for a quote or to discuss your project requirements.

Email: Lock@junsion.com.cn, echo@junsion.com.cn, or evelyn@junsion.com.cn.

Trust Junsion for precision-engineered products that drive your success. Let's build a lasting partnership for all your custom manufacturing needs.