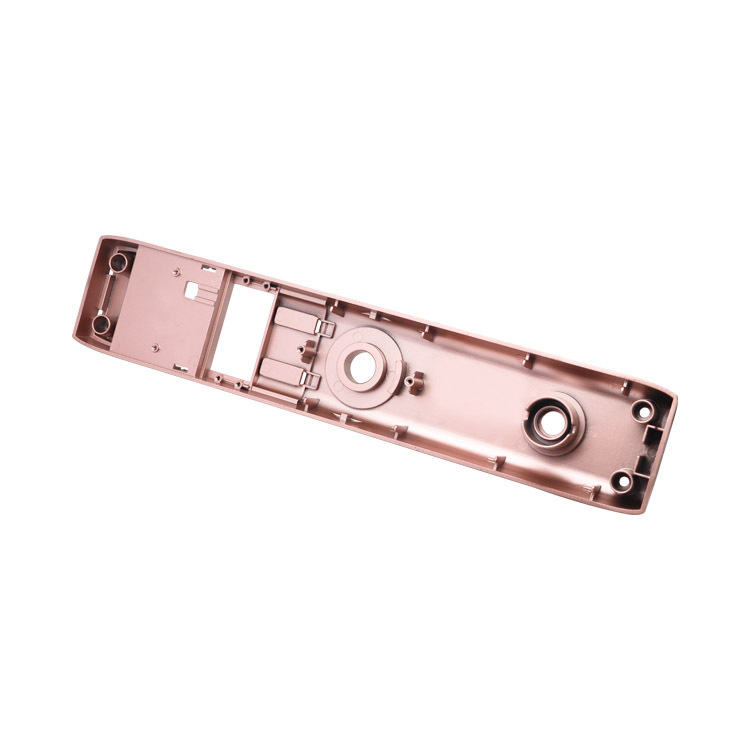

perfume cap

Material: 45 steel,aluminum alloy,stainless steel, plastic,brass

Processing techniques: CNC, EDM, turning, five axis machining, stamping,hobbing, milling, grinding, drilling, tapping, reaming, pulling, cutting, etc

Finish:Polishing, painting, anodizing,sandblasting, plating ,blackening, electrophoresis, QPQ ,wire drawing

- Product Description

Luxury Perfume & Spirit Caps: Precision CNC Machined & Cast Craftsmanship

We are a premier manufacturer specializing in precision metal processing, offering end-to-end solutions from conceptual design to full-scale production. Equipped with state-of-the-art CNC machinery, precision measuring instruments, and a stringent quality management system, we ensure every product surpasses international standards for aesthetics, functionality, and durability.

Our exquisitely crafted perfume caps and spirit bottle closures embody the seamless integration of advanced engineering and artistic design. Each piece is precision-machined or cast to deliver not only a flawless seal but also a tactile and visual experience that elevates your brand.

Core Strengths

Advanced Manufacturing Capabilities

We operate a full suite of advanced CNC lathes, multi-axis machining centers, milling stations, and high-pressure die-casting systems. This allows us to work with a diverse range of materials—from stainless steel and aluminum to brass and titanium—while meeting ultra-tight tolerances across industries.

Key Features:

- Precision Engineering: Machined to ±0.01mm tolerances using state-of-the-art CNC equipment

- Superior Materials: Available in stainless steel, aluminum, titanium, and carbon steel options

- Complete Kit: Includes tube, end caps, thread protectors, and custom spacers

- Multiple Sizes: B-size, C-size, and D-size configurations to meet diverse requirements

- Thread Compatibility: Various thread patterns including 1/2-28, 5/8-24, and metric options

Construction Details:

Every luxury cap undergoes rigorous production stages. Our technicians utilize CNC turning and milling centers to achieve perfect symmetry and seamless assembly. Knurled, fluted, or smooth surface treatments are applied not only for visual appeal but also for secure grip and effortless handling.

For aluminum caps, we employ high-pressure die-casting to create lightweight yet robust structures, followed by precision machining for perfect fit and premium finish. Our casting process allows for intricate designs and undercuts that enhance brand identity while maintaining integrity.

Whether you seek the heft of a weighted perfume cap, the sleek minimalism of a spirit pourer, or the ornate elegance of a limited-edition closure, we deliver solutions that speak to craftsmanship, consistency, and creativity.

| Material | 1) Aluminum: AL 6061-T6, 6063, 7075-T etc. |

| 2) Stainless steel: 303,304,316L, 17-4(SUS630) etc. | |

| 3) Steel: 4140, Q235, Q345B,20#,45# etc. | |

| 4) Titanium: TA1,TA2/GR2, TA4/GR5, TC4, TC18 etc. | |

| 5) Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc. | |

| 5) Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc. | |

| Finish | Sandblasting, Anodize color, Blackenning, Zinc/Nickl Plating, Polish. |

| Power coating, Passivation PVD, Titanium Plating, Electrogalvanizing. | |

| Electroplating chromium, electrophoresis, QPQ(Quench-Polish-Quench). | |

| Electro Polishing,Chrome Plating, Knurl, Laser etch Logo, etc | |

| Main Equipment | STEP,STP,GIS,CAD,PDF,DWG,DXF etc or samples. |

| Tolerance | +/-0.01mm ~ +/-0.05mm |

| Surface roughness | Ra 0.1~3.2 |

| Inspection | Complete inspection lab with Micrometer, Optical Comparator, Caliper Vernier,CMM. |

| Depth Caliper Vernier, Universal Protractor, Clock Gauge, Internal Centigrade Gauge | |

| Capacity | CNC turning work range: φ0.5mm-φ150mm*300mm. |

| CNC milling work range: 510mm*1020mm*500mm. |

Surface Treatment Options

We offer comprehensive surface treatment solutions to enhance durability and appearance:

Available Finishes:

- Anodizing: Provides corrosion resistance and attractive color options

- Electroplating: Ensures long-lasting protective coating

- Sandblasting: Creates uniform matte finish for improved grip

- Brushing: Delivers professional aesthetic appearance

- Cerakote: Military-grade ceramic coating for maximum durability

Material-Specific Treatments:

Different materials receive optimized surface treatments. Aluminum components typically feature anodizing, while stainless steel parts may receive electroplating or brushing treatments based on your specifications.

Solvent Trap Kit Drawing Guide

Our engineering team provides comprehensive drawing support for custom applications. We accept various file formats including CAD drawings, technical sketches, and sample parts for reverse engineering.

- Detailed dimensional specifications

- Material preferences and requirements

- Surface finish specifications

- Thread pattern requirements

- Quantity and delivery timeline

Quality Certification

Quality excellence drives everything we do. Our comprehensive quality management system covers all production aspects:

Certifications and Standards:

RoHS compliance for environmental safety

International quality standards adherence

Material traceability documentation

Dimensional inspection reports

Testing Equipment:

2.5D projectors for dimensional verification

Hardness testers for material properties

Salt spray machines for corrosion resistance

Coordinate measuring machines (CMM) for precision measurement

Quality Control Process:

Every product undergoes three-tier inspection. IQC ensures material quality, IPQC monitors production processes, and OQC verifies final product specifications.

Shipping and Delivery

Our efficient logistics network provides reliable delivery worldwide:

Delivery Timeframes:

Samples: 3 days from order confirmation

Small Batch Orders: 7-10 days production time

Mass Production: 10-15 days depending on quantity

Custom Orders: Timeline varies based on complexity

Why Choose JUNSIONAdvanced Manufacturing Capabilities

Our state-of-the-art facility features the latest CNC equipment including lathes, machining centers, and milling machines. This advanced technology enables us to achieve remarkable precision tolerances.

Comprehensive Service Portfolio

From initial design consultation to final delivery, we provide complete support. Our engineering team offers material selection guidance, structural optimization recommendations, and surface finishing advice.

Global Experience

With clients in Europe, North America, Southeast Asia, and Japan, we understand diverse market requirements. Our products serve consumer electronics, telecommunications, medical equipment, automotive, and industrial automation industries.

Customer-Centric Approach

We follow a "quality first, integrity-based, service-oriented" philosophy. Transparent communication and responsive support ensure successful project outcomes for every client.

Competitive Advantages

Fast turnaround times help you seize market opportunities quickly. Our flexible manufacturing capabilities accommodate both prototype development and mass production requirements.

FAQ

Q: What materials are available for perfume cap manufacturing?

A: We offer stainless steel, aluminum, titanium, carbon steel, and copper options. All materials are RoHS-compliant and suitable for precision machining applications.

Q: Can you accommodate custom thread patterns?

A: Yes, our CNC capabilities allow for various thread specifications including standard and metric patterns. We can machine custom threads based on your drawings.

Q: What is your minimum order quantity?

A: We support both prototype quantities and mass production orders. Minimum quantities vary based on complexity and customization requirements.

Q: Do you provide material certificates?

A: Yes, we provide complete material traceability documentation including certificates of conformance and inspection reports for all orders.

Q: What surface treatments are recommended for different applications?

A: Treatment selection depends on your specific requirements. Our engineers provide recommendations based on environmental conditions, durability needs, and aesthetic preferences.

Q: Can you reverse engineer parts from samples?

A: Absolutely. Our engineering team can create technical drawings from sample parts and recommend improvements for manufacturability and performance.

Contact & Support

Ready to discuss your Solvent Trap Kit requirements? Our experienced team is here to help you find the perfect solution for your specific needs.

Get in Touch:

Email: Lock@junsion.com.cn

Professional Consultation: Our engineers provide technical support and design recommendations

Quick Response: We respond to inquiries within 24 hours

Custom Solutions: Tailored manufacturing services for unique requirements

Next Steps:

Contact us today to discuss your project requirements. We'll provide detailed quotes, technical recommendations, and delivery timelines. Our commitment to quality and customer satisfaction ensures your complete satisfaction with every order.

Trust Dongguan Junsion Precision Hardware Co., Ltd for your precision manufacturing needs. Experience the difference that advanced technology, strict quality control, and customer-focused service can make for your business success.

_1755500226110.jpg)

_1755502812953.jpg)