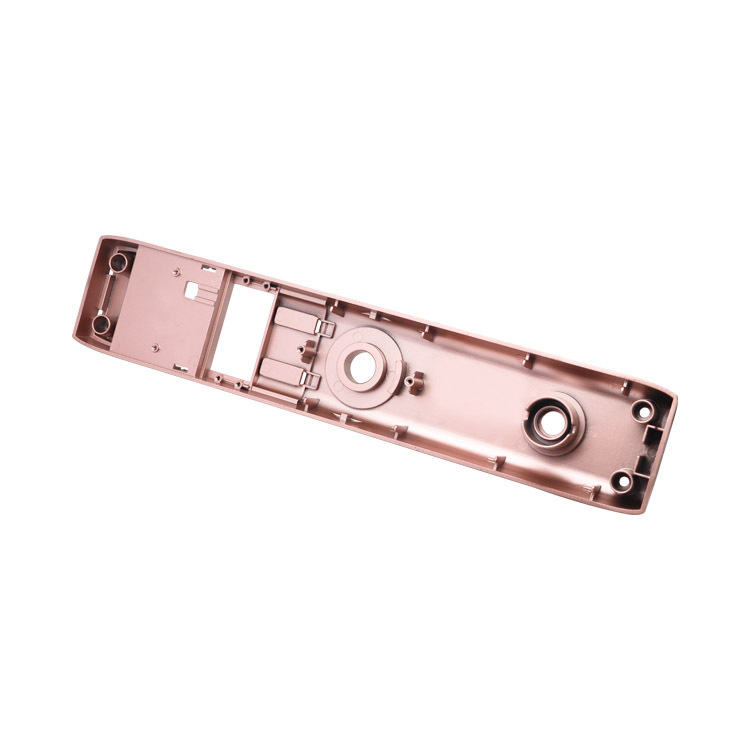

CNC Medical Accessories

Material: 45 steel,aluminum alloy,stainless steel, plastic,brass

Processing techniques: CNC, EDM, turning, five axis machining, stamping,hobbing, milling, grinding, drilling, tapping, reaming, pulling, cutting, etc

Finish:Polishing, painting, anodizing,sandblasting, plating ,blackening, electrophoresis, QPQ ,wire drawing

- Product Description

CNC Medical Accessories: Precision-Engineered Solutions for Healthcare Innovation

At Dongguan Junsion Precision Hardware Co., Ltd., we specialize in manufacturing high-quality CNC medical accessories that meet the exacting standards of the healthcare industry. Medical device makers all over the world trust us as a partner because we offer cutting edge CNC machining and are dedicated to quality and new ideas. We're proud to provide precisely engineered parts that help make technologies that save lives and improve patient results possible.

_1755500272078.jpg)

Description

Our products are made to meet the very strict needs of the healthcare industry. We offer a comprehensive range of components, including:

- Surgical instrument parts

- Implant components

- Diagnostic device elements

- Medical imaging equipment parts

- Orthopedic device components

Each accessory is crafted with meticulous attention to detail, ensuring exceptional precision and consistency. We work with medical-grade materials such as titanium, stainless steel, and PEEK to deliver components that are biocompatible, corrosion-resistant, and durable.

| Material | 1) Aluminum: AL 6061-T6, 6063, 7075-T etc. |

| 2) Stainless steel: 303,304,316L, 17-4(SUS630) etc. | |

| 3) Steel: 4140, Q235, Q345B,20#,45# etc. | |

| 4) Titanium: TA1,TA2/GR2, TA4/GR5, TC4, TC18 etc. | |

| 5) Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc. | |

| 5) Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc. | |

| Finish | Sandblasting, Anodize color, Blackenning, Zinc/Nickl Plating, Polish. |

| Power coating, Passivation PVD, Titanium Plating, Electrogalvanizing. | |

| Electroplating chromium, electrophoresis, QPQ(Quench-Polish-Quench). | |

| Electro Polishing,Chrome Plating, Knurl, Laser etch Logo, etc | |

| Main Equipment | STEP,STP,GIS,CAD,PDF,DWG,DXF etc or samples. |

| Tolerance | +/-0.01mm ~ +/-0.05mm |

| Surface roughness | Ra 0.1~3.2 |

| Inspection | Complete inspection lab with Micrometer, Optical Comparator, Caliper Vernier,CMM. |

| Depth Caliper Vernier, Universal Protractor, Clock Gauge, Internal Centigrade Gauge | |

| Capacity | CNC turning work range: φ0.5mm-φ150mm*300mm. |

| CNC milling work range: 510mm*1020mm*500mm. |

Surface Treatment

To enhance the performance and longevity of our products, we offer various surface treatment options:

- Anodizing: For improved corrosion resistance and aesthetic appeal

- Electropolishing: To create ultra-smooth surfaces for reduced bacterial adhesion

- Passivation: To increase corrosion resistance of stainless steel components

- Coating: Application of specialized coatings for enhanced functionality

Our surface treatments comply with industry standards and are tailored to meet specific product requirements.

Drawing Guide

We work closely with our clients to bring their designs to life. Our engineering team supports you throughout the process:

- Initial consultation to understand your requirements

- 3D modeling and prototyping for design validation

- Material selection guidance based on application needs

- Design for manufacturability (DFM) recommendations

- Iterative refinement to optimize performance and cost-effectiveness

Production Process

Our advanced production process ensures consistent quality and efficiency:

- Material sourcing and verification

- CNC programming and setup

- Precision machining with tolerances up to ±0.005mm

- In-process quality checks (IPQC)

- Surface treatment application

- Final inspection and quality assurance

- Packaging and preparation for shipment

Quality Certification

We maintain rigorous quality standards to meet the demands of the medical industry:

- ISO 13485:2016 certified for medical device manufacturing

- FDA registered facility

- CE marking compliance for applicable products

- Adherence to Good Manufacturing Practices (GMP)

Throughout the production process, our quality control system makes sure that everything can be tracked, that standards are met, and that regulations are followed.

Shipping and Delivery

We know how important it is for medical component supply lines to work well. Our shipping and delivery process is designed for reliability and efficiency:

- Secure, contamination-free packaging

- Expedited shipping options available

- Real-time order tracking

- Just-in-time (JIT) delivery capabilities

- Global logistics network for worldwide distribution

Why Choose Us?

- Expertise in Medical Manufacturing: With years of experience in CNC medical accessories, we understand the unique challenges of the healthcare industry.

- Cutting-Edge Technology: Our advanced CNC machinery and quality control equipment ensure unparalleled precision and consistency.

- Customization Capabilities: We offer tailored solutions to meet your specific product requirements and design specifications.

- Regulatory Compliance: Our robust quality management system ensures adherence to international medical device standards.

- Competitive Pricing: We balance cost-effectiveness with premium quality, offering excellent value for your investment.

- Responsive Customer Service: Our dedicated team gives you personalized help throughout the entire lifecycle of your job.

FAQ

Q: What materials do you use for the products?

A: Titanium, stainless steel, aluminum, and PEEK are some of the medical-grade products we work with.

Q: Can you handle both prototyping and large-scale production?

A: Yes, we can do a wide range of production methods, from fast prototyping to making a lot of products.

Q: How do you ensure the quality of your products?

A: We use a full quality control system that includes checks during the process, final inspections, and high-tech testing tools.

Q: What is your typical lead time for the products?

A: Lead times vary depending on the complexity and volume of the order. We offer expedited services for urgent requirements.

Q: Do you provide design assistance for the products?

A: Yes, our engineering team can help you improve the performance and cost-effectiveness of your product by suggesting design improvement and manufacturability.

Contact & Support

Ready to elevate your medical device manufacturing with precision-engineered products? Contact our expert team today to discuss your project requirements and experience the JUNSION difference.

Email: Lock@junsion.com.cn, echo@junsion.com.cn, or evelyn@junsion.com.cn.

Partner with Dongguan Junsion Precision Hardware Co., Ltd. for innovative, high-quality CNC medical accessories that drive healthcare advancements and improve patient care.

_1755500272078.jpg)

_1755500272106.jpg)

_1763437634980.jpg)

_1755500226110.jpg)