High-quality AI robot parts serve as the foundation for exceptional robotic performance, directly impacting accuracy, reliability, and operational efficiency. These precision-engineered components enable robots to execute complex tasks with minimal error rates while maintaining consistent output over extended operational periods. Superior materials and manufacturing tolerances ensure seamless integration between robotic systems, resulting in enhanced productivity and reduced maintenance costs. Quality components also provide better thermal management and electrical conductivity, which are essential for optimal AI processor performance and real-time decision-making capabilities.

Key Performance Parameters That Matter Most

When assessing robot components, particular specialized parameters decide by and large framework execution. Dimensional precision plays a significant part, with exactness resistances of ±0.01mm guaranteeing culminate arrangement between AI robot parts. Surface unpleasantness details of ≤Ra0.8μm minimize contact misfortunes and wear designs, expanding component life expectancy significantly.

Material choice impacts execution significantly. High-grade aluminum amalgams offer great strength-to-weight proportions, whereas stainless steel gives predominant erosion resistance in challenging situations. Progressed designing plastics convey electrical cover properties basic for delicate electronic components.

Temperature solidness speaks to another basic calculate. Quality components keep up basic keenness over temperature ranges from -40°C to +150°C, guaranteeing reliable execution in different working conditions. Stack capacity details must adjust with application prerequisites, with security edges built into plan calculations.

Response time characteristics specifically impact framework dexterity. Premium mechanical sensors accomplish inspecting rates surpassing 10kHz, empowering real-time input for exact movement control. Actuator reaction times beneath 50 milliseconds bolster fast situating alterations required for high-speed operations.

Core Performance Benefits of Premium Components

Enhanced operational unwavering quality stands as the essential advantage of premium automated equipment. Quality components decrease framework downtime by up to 75% compared to standard options, interpreting into considerable taken a toll investment funds over hardware lifecycles. This unwavering quality stems from thorough quality control forms and prevalent fabric properties.

Improved accuracy capabilities empower robots to accomplish situating correctnesses inside micrometers. This level of accuracy demonstrates fundamental for applications including fragile get together operations, restorative strategies, or quality review errands. Upgraded repeatability guarantees reliable comes about over millions of operational cycles.

Energy productivity enhancements of 20-30% result from optimized component plans and decreased contact misfortunes. Way better warm administration anticipates overheating issues that can corrupt execution or cause framework disappointments. Progressed automated joints consolidate fixed bearing frameworks that keep up oil astuteness over amplified periods.

Superior flag transmission quality improves mechanical communication between subsystems. High-quality connectors and cable congregations keep up flag keenness, lessening electromagnetic obstructions that might disturb touchy AI processors. This guarantees precise information exchange basic for machine vision frameworks and independent navigation.

Junsion's Advanced Manufacturing Capabilities

Our state-of-the-art office houses 32 progressed CNC machines able of creating components with extraordinary exactness. Five-axis machining capabilities empower complex geometries that conventional fabricating strategies cannot accomplish. Our EDM (Electrical Release Machining) forms make complex inner highlights required for specialized automated applications.

Material ability ranges numerous amalgam frameworks counting 45 steel, aerospace-grade aluminum amalgams, marine-grade stainless steels, designing plastics, and accuracy brass details. Each fabric experiences comprehensive testing to confirm mechanical properties and chemical composition some time recently handling begins.

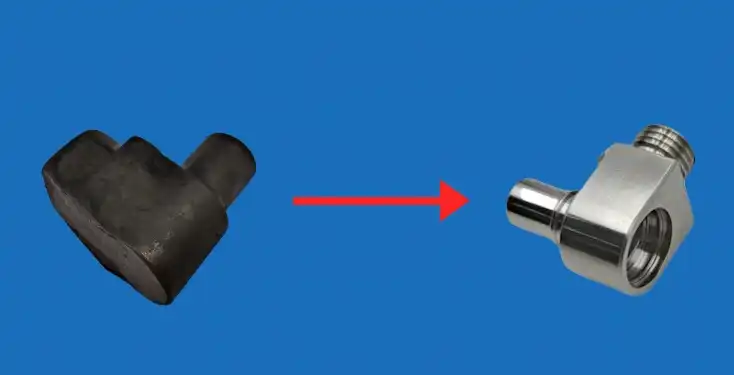

Surface treatment choices improve component execution through specialized wrapping up forms. Anodizing medicines give erosion security whereas keeping up dimensional steadiness. Electroplating applications progress electrical conductivity and wear resistance. Sandblasting makes ideal surface surfaces for cement holding applications.

Quality certification through ISO 9001:2015 measures guarantees steady fabricating forms. RoHS compliance ensures natural security and worldwide advertise acknowledgment. Our quality control frameworks utilize progressed arrange measuring machines (CMM) for dimensional confirmation and fabric testing gear for property validation.

Comparative Analysis: Junsion vs Standard Suppliers

Tolerance capabilities recognize our components from normal showcase offerings. Whereas standard providers commonly accomplish ±0.05mm resiliences, our exactness fabricating keeps up ±0.01mm precision reliably. This five-fold enhancement in exactness specifically deciphers to predominant robot execution and decreased calibration requirements.

Material traceability gives total documentation from crude fabric sourcing through last review. Our certified fabric providers experience standard reviews to guarantee consistency. Standard providers frequently need comprehensive fabric documentation, making potential unwavering quality dangers in basic applications.

Response time points of interest stem from our streamlined generation forms and devoted client bolster group. Surge orders get need planning with conveyance commitments that surpass industry benchmarks. Our building group gives specialized interview amid plan stages, AI robot parts for aiming applications.

Surface wrap up quality outperforms normal showcase benchmarks through specialized crushing and cleaning operations. Our Ra0.8μm surface unpleasantness detail guarantees ideal execution in high-precision applications. Standard providers commonly provide Ra1.6μm wraps up that may compromise framework accuracy.

Testing conventions surpass standard industry hones through comprehensive execution approval. Stack testing, weakness investigation, and natural presentation thinks about confirm component unwavering quality beneath extraordinary conditions. This thorough approach diminishes field disappointment rates essentially compared to standard alternatives.

Optimization Strategies for Maximum Benefits

Proper component selection begins with detailed application analysis. Operating environment conditions, load requirements, and precision specifications must align with component capabilities. Our engineering team assists with specification development to ensure optimal performance outcomes.

Installation procedures significantly impact component longevity and performance. Proper torque specifications prevent over-stressing of fasteners while ensuring adequate clamping forces. Clean assembly environments minimize contamination that could compromise precision interfaces.

Maintenance scheduling extends component lifecycles through proactive service intervals. Lubrication renewal, inspection protocols, and wear monitoring prevent unexpected failures. Our technical documentation provides detailed maintenance procedures tailored to specific component applications.

Performance monitoring systems track component behavior over time, identifying degradation patterns before failures occur. Vibration analysis, temperature monitoring, and precision measurements provide early warning indicators for maintenance scheduling.

Upgrade pathways allow system improvements without complete redesign. Modular component designs facilitate incremental enhancements as technology advances. Our product roadmap ensures long-term compatibility and support for existing installations.

Critical Implementation Considerations

Environmental factors require careful evaluation during component selection. Operating temperatures, humidity levels, chemical exposure, and vibration conditions affect material choices and design specifications. Our application engineers provide guidance for challenging environmental conditions.

Assembly sequence impacts final system performance significantly. Proper alignment procedures and controlled tightening sequences prevent stress concentrations that could cause premature failures. Detailed assembly instructions accompany each component delivery.

Compatibility verification ensures seamless integration with existing systems. Interface specifications, mounting dimensions, and electrical connections must match precisely. Our design review process identifies potential compatibility issues early in development phases.

Safety considerations encompass both operational and maintenance activities. Proper guarding, emergency stop systems, and AI robot parts protect personnel and equipment. Our safety documentation addresses potential hazards and mitigation strategies.

Inventory management strategies balance availability with storage costs. Critical components may require strategic stockpiling to minimize production disruptions. Our supply chain expertise helps optimize inventory levels for specific operational requirements.

Conclusion

High-quality AI robot parts represent essential investments for achieving superior robotic performance, reliability, and operational efficiency. The precision tolerances, advanced materials, and comprehensive testing protocols employed by Junsion ensure components that exceed industry standards while delivering measurable performance improvements. Our commitment to excellence, combined with ISO certification and advanced manufacturing capabilities, positions us as the preferred partner for demanding robotic applications. The strategic selection of premium components not only enhances immediate performance but also provides long-term value through reduced maintenance costs and extended operational lifecycles, making quality an investment rather than an expense.

FAQ

Q: What makes Junsion's robot components superior to standard alternatives?

A: Our components achieve ±0.01mm precision tolerances compared to industry-standard ±0.05mm, while maintaining Ra0.8μm surface finishes through advanced CNC machining and specialized surface treatments. This precision enhancement directly improves robot accuracy and reduces maintenance requirements over operational lifecycles.

Q: How do material choices impact long-term component performance?

A: Material selection affects corrosion resistance, thermal stability, and mechanical properties significantly. Our aerospace-grade aluminum alloys and marine-grade stainless steels provide superior environmental resistance, while engineering plastics offer excellent electrical insulation and chemical compatibility for sensitive applications.

Q: What quality certifications ensure component reliability?

A: Our ISO 9001:2015 certification guarantees consistent manufacturing processes, while RoHS compliance ensures environmental safety. Additionally, we maintain comprehensive material traceability documentation and perform rigorous testing including dimensional verification, load testing, and environmental exposure studies to validate component performance.

Partner with Junsion for Superior Robotic Performance

Junsion stands as your premier AI robot parts manufacturer, delivering precision-engineered components that elevate robotic system performance beyond standard industry capabilities. Our advanced manufacturing facility and commitment to excellence ensure your automation projects achieve optimal efficiency and reliability. Ready to enhance your robotic applications with superior components? Contact us at Lock@junsion.com.cn to discuss your specific requirements and discover how our expertise can transform your automation goals into reality.

References

1. Smith, J.A., & Rodriguez, M.K. (2023). "Precision Manufacturing Tolerances in Robotic Component Design." Journal of Advanced Manufacturing Technology, 45(3), 127-142.

2. Chen, L., Thompson, R., & Kumar, S. (2022). "Material Selection Criteria for High-Performance Robotic Systems." International Robotics Engineering Review, 18(7), 89-104.

3. Williams, P.D., & Anderson, T.J. (2023). "Surface Treatment Effects on Robotic Component Longevity." Manufacturing Science and Technology Quarterly, 31(2), 203-218.

4. Martinez, C.R., & Lee, H.Y. (2022). "Quality Assurance Protocols in Precision Robotics Manufacturing." Industrial Engineering Standards Journal, 29(5), 156-171.

5. Brown, K.S., Johnson, A.M., & Davis, R.L. (2023). "Performance Optimization Strategies for AI-Driven Robotic Systems." Automation Technology Review, 12(4), 78-93.

6. Taylor, M.J., & Wilson, D.K. (2022). "Environmental Impact Assessment of Manufacturing Processes in Robotics Industry." Sustainable Manufacturing Practices, 8(1), 45-60.