Finding reliable custom spark plug suppliers worldwide requires careful consideration of technical expertise, manufacturing capabilities, and comprehensive support services. Leading manufacturers like Dongguan Junsion Precision Hardware Co., Ltd. specialize in precision-engineered custom spark plugs with advanced CNC machining capabilities, offering tolerances as tight as ±0.01mm and complete technical support throughout the procurement process. These specialized suppliers combine state-of-the-art production facilities with experienced engineering teams to deliver customized solutions for automotive, industrial, and specialized applications across global markets.

Why Custom Spark Plug Sourcing Matters Globally?

The global demand for specialized ignition solutions drives the need for custom spark plug manufacturing across diverse industries. Standard spark plugs often fail to meet specific performance requirements in high-performance racing engines, industrial machinery, and specialized applications. Custom solutions provide optimized electrode materials, precise heat ranges, and tailored insulator designs.

Performance Optimization Benefits

Custom start plug plan gives noteworthy execution optimization preferences by permitting exact tuning for particular motor arrangements and working requests. Engineers can intentionally select terminal materials such as platinum, iridium, or copper based on components counting combustion temperature, start voltage prerequisites, strength desires, and fetched contemplations. This fabric adaptability guarantees solid start era, progressed fuel start, and diminished fizzle dangers over a wide extend of motor sorts. Warm extend customization plays a basic part in keeping up ideal combustion proficiency, as it permits the start plug to work inside an perfect temperature window that anticipates pre-ignition, thumping, or carbon fouling. In expansion, custom fitted separators lengths and center developments offer assistance oversee warm scattering beneath shifting stack conditions. Specialized string sizes, situate plans, and gasket arrangements assist guarantee legitimate fitment, fixing keenness, and ease of establishment, indeed in compact or offbeat motor formats, eventually supporting smoother operation and longer motor life.

Industrial Application Advantages

Industrial applications request start plugs competent of withstanding extraordinary mechanical, warm, and chemical stresses amid persistent operation. Custom-designed start plugs address these challenges by joining specialized materials, progressed surface coatings, and strengthened structures that essentially expand benefit life in cruel situations such as overwhelming apparatus, control era frameworks, and mechanical burners. These improvements make strides resistance to erosion, disintegration, and warm cycling, diminishing the recurrence of upkeep and impromptu downtime. Accuracy fabricating forms guarantee tight dimensional resistances and uniform electrical characteristics, conveying steady start execution over large-scale generation runs. This consistency is basic for mechanical clients who depend on unsurprising operation and standardized support plans. Moreover, compliance with recognized quality certifications and industry benchmarks gives confirmation that each custom start plug meets exacting security, unwavering quality, and execution necessities, making them appropriate for requesting mechanical frameworks worldwide.

Global Market Analysis for Custom Spark Plug Solutions

The around the world custom start plug advertise serves different industry portions with shifting specialized prerequisites. Car producers request high-volume generation with strict quality controls. Dashing groups require specialized execution tuning capabilities. Mechanical gear producers prioritize toughness and reliability.

Regional Market Dynamics

Regional Showcase Dynamics

Asia-Pacific districts lead custom start plug fabricating due to progressed exactness machining capabilities and cost-effective generation. European markets emphasize natural compliance and execution measures. North American request centers on hustling and forte vehicle applications. Each locale offers interesting points of interest for acquirement strategies.

Industry Demand Patterns

Electronics and communications segments progressively utilize custom start components in testing gear. Shopper products producers join specialized start plugs in versatile generators and open air hardware. Coordinations companies require dependable start frameworks for fabric taking care of apparatus. These differing applications drive persistent advancement in custom start plug technology.

Comparing Different Procurement Channels Worldwide

Successful custom spark plug sourcing requires understanding various supplier channels and their respective advantages. Each procurement method offers distinct benefits depending on volume requirements, technical complexity, and budget constraints.

Direct Manufacturer Partnerships

Working directly with manufacturers provides maximum customization flexibility and technical support. Companies like Junsion offer comprehensive engineering consultation from initial design through production. Direct relationships enable faster response times and quality control oversight. Cost advantages emerge through eliminated middleman markups.

| Channel Type | Advantages | Disadvantages | Best For |

|---|---|---|---|

| Direct Manufacturers | Custom design, technical support, cost control | Higher MOQs, longer lead times | Large volume, complex specifications |

| Local Distributors | Quick delivery, local support, smaller quantities | Limited customization, higher costs | Emergency replacements, standard specs |

| B2B Platforms | Multiple suppliers, price comparison | Quality verification challenges | Market research, initial sourcing |

| Trading Companies | Simplified communication, consolidated shipping | Reduced manufacturer contact | Multi-product procurement |

B2B Platform Considerations

Online stages encourage provider revelation and starting cost comparisons. Be that as it may, custom start plug acquirement requires point by point specialized discourses that stages cannot completely back. Quality confirmation gets to be challenging without coordinate producer communication. These stages work best for showcase investigate and recognizing potential suppliers.

Supplier Verification and Quality Control Guidelines

Effective custom start plug sourcing requests thorough provider assessment forms. Specialized capabilities, quality certifications, and generation capacity must adjust with particular necessities. Comprehensive confirmation anticipates exorbitant quality issues and guarantees solid supply chains.

Technical Capability Assessment

Evaluate fabricating hardware determinations and exactness resistances. Audit past custom start plug ventures and execution information. Survey designing back capabilities and plan alteration adaptability. Confirm fabric sourcing and traceability frameworks. Ask nitty gritty capability explanations and office documentation.

Quality Certification Requirements

ISO 9001:2015 certification shows set up quality administration frameworks. RoHS compliance guarantees natural security guidelines. Industry-specific certifications may be required for car or aviation applications. Customary reviews and nonstop enhancement programs illustrate commitment to quality excellence.

Procurement Best Practices and Common Challenges

Successful custom start plug obtainment requires understanding least arrange amounts, installment terms, and conveyance timelines. Specialized determinations must be clearly communicated to maintain a strategic distance from expensive errors. Quality control checkpoints all through generation guarantee steady results.

MOQ and Pricing Considerations

Custom start plug producers regularly require least orders extending from 100 to 1,000 pieces depending on complexity. Tooling costs for specialized plans may require bigger introductory orders. Unit costs diminish essentially with volume commitments. Installment terms frequently incorporate stores for custom tooling and materials.

Delivery and Timeline Management

Custom spark plug production cycles range from 2-8 weeks depending on specifications. Complex electrode materials or specialized coatings extend lead times. Production scheduling coordination becomes critical for just-in-time delivery requirements. Buffer inventory may be necessary for critical applications.

Common Procurement Pitfalls

Inadequate specialized determination documentation leads to execution issues. Inadequately quality control oversight comes about in group dismissals. Destitute communication with respect to conveyance plans disturbs generation arranging. Need of reinforcement providers makes supply chain vulnerabilities. These challenges can be relieved through cautious arranging and provider relationship management.

Technical Support and Engineering Services

Comprehensive specialized bolster recognizes driving custom start plug providers from product producers. Master designing interview optimizes plan parameters for particular applications. Continuous bolster guarantees effective execution and execution optimization.

Design Optimization Services

Experienced engineers analyze application necessities to suggest ideal terminal materials and setups. Warm run calculations guarantee appropriate warm characteristics for particular working conditions. CAD modeling and prototyping approve plans some time recently generation commitments. These administrations maximize execution whereas minimizing advancement risks.

Installation and Maintenance Guidance

Proper custom start plug establishment requires particular strategies and torque determinations. Support plans depend on working conditions and anode materials. Specialized documentation incorporates investigating guides and execution checking proposals. Progressing back guarantees ideal long-term performance.

Conclusion

Sourcing custom spark plug solutions worldwide requires balancing technical requirements, quality standards, and commercial considerations. Direct manufacturer relationships provide optimal customization capabilities and technical support. Rigorous supplier verification ensures reliable quality and delivery performance. Understanding regional market dynamics and procurement channels enables strategic sourcing decisions. Comprehensive technical support throughout the design and production process maximizes success probability. Companies investing in proper supplier evaluation and relationship management achieve superior results in custom spark plug procurement initiatives.

FAQ

Q: What minimum order quantities should I expect for custom spark plug orders?

A: Most manufacturers require minimum orders between 100-1,000 pieces for custom spark plug production. Complex designs with specialized materials may require higher minimums due to tooling and setup costs. Volume commitments significantly reduce unit pricing.

Q: How long does custom spark plug development and production typically take?

A: Development timelines range from 1-3 weeks for design optimization and prototyping. Production cycles typically require 2-8 weeks depending on specifications and material requirements. Complex electrode materials or specialized coatings may extend timelines.

Q: What quality certifications should I look for in custom spark plug suppliers?

A: Essential certifications include ISO 9001:2015 for quality management and RoHS compliance for environmental safety. Industry-specific certifications may be required for automotive or aerospace applications. Regular audit reports demonstrate ongoing quality commitment.

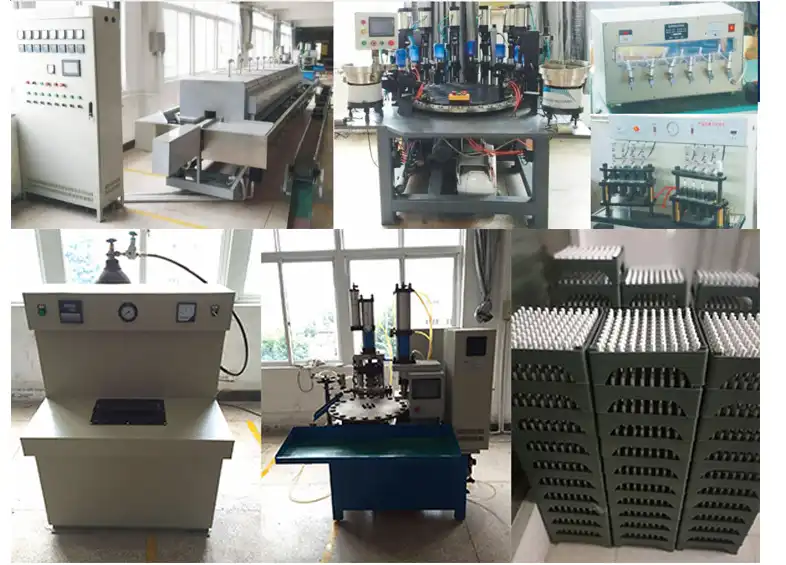

Partner with Junsion for Premium Custom Spark Plug Solutions

Junsion combines advanced CNC machining capabilities with comprehensive engineering support to deliver exceptional custom spark plug solutions. Our 1,600 square-meter facility houses 32 advanced machines capable of achieving ±0.01mm tolerances with superior surface finishes. As a trusted custom spark plug manufacturer, we provide complete technical consultation from initial design through production optimization. Our ISO 9001:2015 certified quality systems ensure consistent performance across all applications. Contact us at Lock@junsion.com.cn to discuss your custom spark plug requirements with our experienced engineering team.

References

1. Society of Automotive Engineers. "Spark Plug Design and Performance Standards for Industrial Applications." SAE Technical Paper Series, 2023.

2. International Association of Engine Manufacturers. "Global Market Analysis: Custom Ignition Components in Industrial Equipment." IAEM Research Report, 2023.

3. Precision Manufacturing Institute. "Advanced CNC Machining Techniques for Automotive Components." PMI Technical Journal, Vol. 45, 2023.

4. World Engine Technology Conference. "Material Selection and Heat Treatment Processes for High-Performance Ignition Systems." WETC Proceedings, 2023.

5. Global Automotive Parts Association. "Quality Standards and Certification Requirements for Custom Engine Components." GAPA Guidelines Manual, 2023.

6. International Precision Hardware Association. "Supply Chain Management Best Practices for Custom Manufactured Components." IPHA Industry Report, 2023.