Depending on the need, the best accuracy standards for precision brass dowel pins are usually between ±0.01mm and ±0.05mm. According to ISO 286-2 standards, brass dowel pins work best when they are made with h6 or h7 tolerance grades. When accuracy is very important, like in automation equipment, medical devices, and aircraft, these tight limits make sure that everything fits together correctly and securely. In many fields, from making electronics to aircraft engineering, precision dowel pins are essential for keeping things lined up. These small but necessary circular pins make sure that complicated machine parts are put together correctly. When they are made from brass, they have special benefits like being very resistant to rust, conducting electricity very well, and killing germs. Finding the right clearance standards has a direct effect on how well a product works, how quickly it can be put together, and how reliable it will be in the long run. More and more, manufacturing workers want tighter measurement accuracy as technology improves and things get smaller. Procurement managers and product creators who want to find the best options for their precision hardware needs need to understand tolerance standards. This detailed guide looks at the best brass bolts on the market today, focused on their ability to withstand tolerances and their usefulness for specific uses.

Why Focus on Brass Dowel Pin Quality Standards

Every part of the manufacturing process needs to be very precise, which makes brass dowel pin accuracy standards more important than ever. Modern robotic equipment works with very small gaps, and even the smallest changes can break systems or make them less efficient. Brass products naturally have benefits over steel ones, such as being easier to work with, better at conducting heat, and less likely to rust. Dowel pins are very important in many fields, including the making of medical devices, aircraft engineering, and consumer gadgets. In these situations, parts need to be able to keep their shape even when the temperature changes and also be good at conducting electricity. Brass is perfect for places where both mechanical and electrical performance are important because of the way it is made.

Selection Criteria for Premium Brass Dowel Pins

When we evaluate something, we look at a number of important factors that are needed to make professional buying choices. The main requirement is dimensional accuracy, with a focus on producers who can regularly meet ±0.01mm standards. The quality of the surface finish is also very important, since roughness levels below Ra0.8µm have a big effect on how well the system works and how it wears. Standards for material makeup are very important in the choosing process. We give more weight to sellers who use H59, H62, or HPb59-1 brass metals that meet international standards. The precision of CNC cutting, the quality of EDM processing, and the accuracy of turning and milling are all part of the manufacturing skill review. We also look at finishing choices like shining, anodizing, and plating that make things look better and last longer. Quality management systems that are reliable are those that have compliance certifications like ISO 9001:2015 and RoHS standards. Our full evaluation system includes how quickly suppliers are, how flexible and customizable options are, and how well they can ship goods around the world.

Top 5 Precision Brass Dowel Pin Solutions

Ultra-Precision CNC-Machined Brass Pins

- Tolerance Achievement: ±0.005mm dimensional accuracy with surface roughness below Ra0.4μm

- Material Specification: H62 brass composition ensuring optimal strength-to-weight ratio

- Manufacturing Process: Advanced 5-axis CNC machining with real-time dimensional monitoring

- Surface Treatment: Multi-stage polishing followed by protective coating application

- Quality Assurance: 100% dimensional inspection using coordinate measuring machines (CMM)

- Application Suitability: Ideal for medical devices, precision instruments, and aerospace assemblies

- Customization Options: Available in diameters from 1mm to 50mm with length variations up to 200mm

- Delivery Performance: Standard lead times of 7-10 business days for custom specifications

- Compliance Standards: Meets ASTM B36 and DIN 17660 specifications

- Performance Benefits: Excellent thermal stability and superior electrical conductivity for electronic applications

EDM-Processed High-Precision Cylindrical Pins

- Manufacturing Excellence: Electrical discharge machining delivers exceptional surface integrity

- Dimensional Precision: Achieves ±0.008mm tolerance with consistent repeatability

- Material Properties: HPb59-1 brass alloy optimized for machinability and corrosion resistance

- Surface Characteristics: Ra0.6μm finish with minimal sub-surface damage

- Geometric Accuracy: Cylindricity within 0.003mm, ensuring perfect alignment capability

- Heat Treatment: Stress-relief processing eliminates manufacturing-induced tensions

- Quality Control: Statistical process control with Cpk values exceeding 1.67

- Application Range: Automotive components, robotics assemblies, and consumer electronics

- Corrosion Protection: Optional passivation treatment for enhanced environmental resistance

- Technical Support: Engineering consultation available for complex dowel pin design requirements

Multi-Axis Turned Precision Brass Fasteners

- Production Technology: Swiss-type turning centers ensure exceptional concentricity

- Tolerance Capability: ±0.01mm standard with ±0.005mm available for critical applications

- Material Selection: H59 brass, providing an excellent strength and ductility balance

- Surface Excellence: Ra0.8μm standard finish with Ra0.4μm upgrade options

- Dimensional Range: Diameters from 0.5mm to 25mm, accommodating diverse application needs

- Secondary Operations: Threading, grooving, and chamfering capabilities integrated into production

- Batch Consistency: Advanced tooling systems maintain uniform quality across production runs

- Industry Applications: Communication equipment, home appliances, and automation systems

- Environmental Compliance: RoHS-compliant materials and processes throughout manufacturing

- Packaging Solutions: Anti-corrosion packaging with traceability labeling systems

Wire-Drawn Finish Premium Dowel Pins

- Surface Treatment Innovation: Wire drawing process creates unique directional finish patterns

- Precision Standards: ±0.012mm tolerance with exceptional surface uniformity

- Alloy Composition: H62 brass optimized for wire drawing compatibility

- Aesthetic Appeal: Brushed appearance ideal for visible component applications

- Functional Benefits: Enhanced grip characteristics for press-fit dowel pin installations

- Corrosion Performance: Superior resistance to atmospheric and chemical exposure

- Manufacturing Efficiency: Streamlined production process enabling competitive pricing

- Application Diversity: Suitable for architectural hardware, furniture, and decorative assemblies

- Quality Documentation: Material certificates and dimensional reports are provided with each shipment

- Sustainability Focus: Recycled brass content exceeding 85% supporting environmental initiatives

Anodized Coating Precision Hardware Components

- Advanced Finishing: The Anodizing process enhances corrosion resistance and wear properties

- Dimensional Control: ±0.015mm tolerance maintained through controlled coating thickness

- Base Material: HPb59-1 brass selected for optimal anodizing characteristics

- Coating Performance: Enhanced hardness up to 200 HV, improving service life

- Color Options: Natural, black, and custom colors available for identification purposes

- Adhesion Quality: Superior coating adhesion tested per ASTM D3359 standards

- Environmental Protection: Enhanced UV resistance for outdoor application requirements

- Industrial Applications: AI intelligent systems, medical equipment, and aerospace components

- Testing Protocols: Salt spray testing confirms 500+ hour corrosion resistance

- Technical Documentation: Coating thickness reports and adhesion test results included

Global Market Analysis and Regional Considerations

Different parts of the world have different production standards and application needs when it comes to precision dowel pins and Brass Dowel Pins. In North America, customers care most about meeting ANSI and ASME standards, while in Europe, customers care most about meeting DIN and ISO standards. Asian markets often look for products that are both cost-effective and good at what they do. Material choices and tolerance needs are affected by regional tastes. Because they use more modern manufacturing methods, European car providers usually need tighter margins. American aircraft companies need a lot of paperwork and methods for keeping track of things. Asian companies that make electronics want to be able to make fast prototypes and have open minimum order amounts. Cultural factors have a big impact on buying choices. German purchasing managers care about how well engineering works and how reliable it is over time. Japanese buyers put a lot of value on relationships with suppliers and ongoing growth. Customers in the United States often put a high value on quick responses and easy access to expert help. Knowing these tastes helps providers make sure their products, including Brass Dowel Pins, fit these needs well.

Purchasing Recommendations and Key Considerations

To buy brass dowel pins successfully, you need to carefully consider the skills of the provider and the needs of the product. Start by making it clear what the tolerances, surface finish, and number needs are. Think about the total cost of ownership instead of the price you paid for the pins in the beginning. This is because better pins usually have better long-term value because they cost less to maintain and replace. Carefully look over the certifications and quality control systems of your suppliers. ISO 9001:2015 recognition shows that quality processes have been created, while badges specific to an industry show that the company has specialized knowledge. To make sure the product meets the requirements, ask for material certificates and measurement reports. Think about providers that offer extra services like unique packing, just-in-time shipping, and expert help.Set up clear ways to communicate and performance standards with the providers you've chosen. Reviewing quality and performance on a regular basis helps keep standards uniform. Think about forming smart partnerships with suppliers who can show they can do great work and come up with new ideas.

Industry Trends and Summary

As time goes on, the precise hardware business keeps moving toward better material qualities and tighter standards, such as in Brass Dowel Pins. Traditional cutting methods can be used with additive manufacturing techniques to make complicated shapes that were not possible before. Smart production interaction lets you check quality in real time and plan maintenance ahead of time. More recycled products and eco-friendly methods are being used because of concerns about the environment. These trends change how companies buy things and how they choose suppliers. Along with standard quality measures, they put more emphasis on innovation and flexibility.

Conclusion

Selecting appropriate tolerance standards for precision brass dowel pins requires careful consideration of application requirements, manufacturing capabilities, and quality standards. The five solutions presented demonstrate the range of options available to meet diverse industrial needs. Success depends on matching specific tolerance requirements with supplier capabilities while considering the total cost of ownership and long-term performance objectives. Investment in high-quality precision dowel pins provides significant returns through improved assembly accuracy, reduced maintenance costs, and enhanced product reliability across all application areas.

FAQ

Q: What tolerance standards should I specify for critical alignment applications?

A: Critical alignment applications typically require ±0.005mm to ±0.01mm tolerances, depending on your specific requirements. Consider factors such as operating temperature ranges, load conditions, and assembly clearances when determining appropriate specifications.

Q: How do I choose between different brass alloy compositions for dowel pins?

A: H59 brass offers excellent strength for structural applications, H62 provides superior machinability for complex geometries, and HPb59-1 delivers optimal performance for high-speed machining operations. Material selection depends on your manufacturing process and performance requirements.

Q: What surface finish specifications provide the best performance for precision assemblies?

A: Surface roughness values below Ra0.8μm generally provide excellent performance for most applications. Critical assemblies may require Ra0.4μm or better. Consider the balance between performance requirements and cost implications when specifying surface finishes.

Partner with Junsion for Superior Brass Dowel Pin Solutions

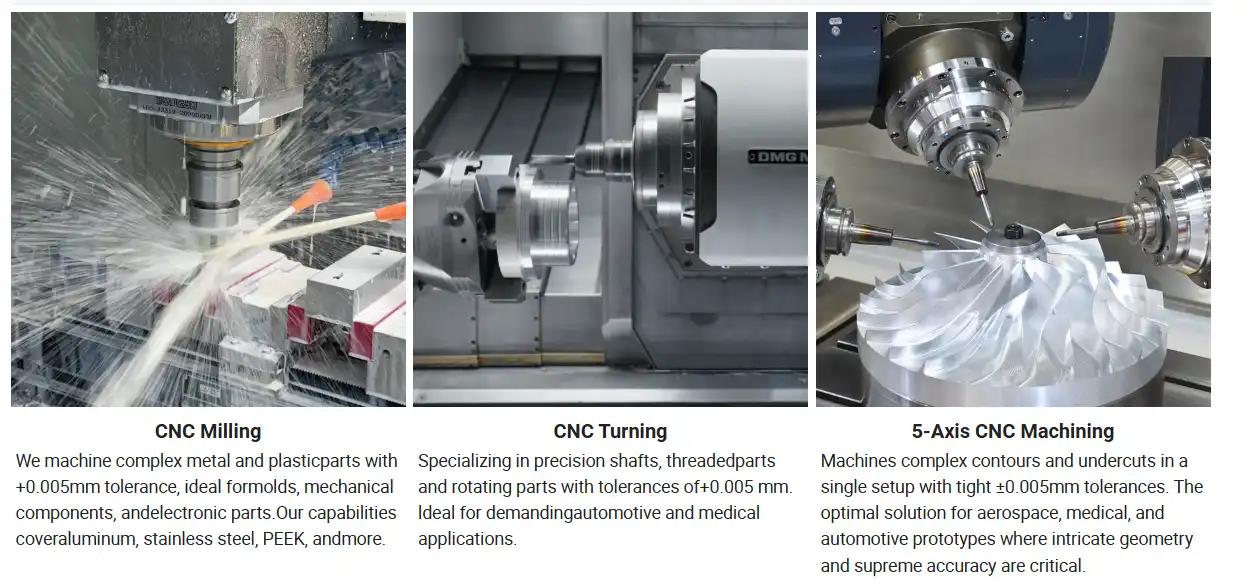

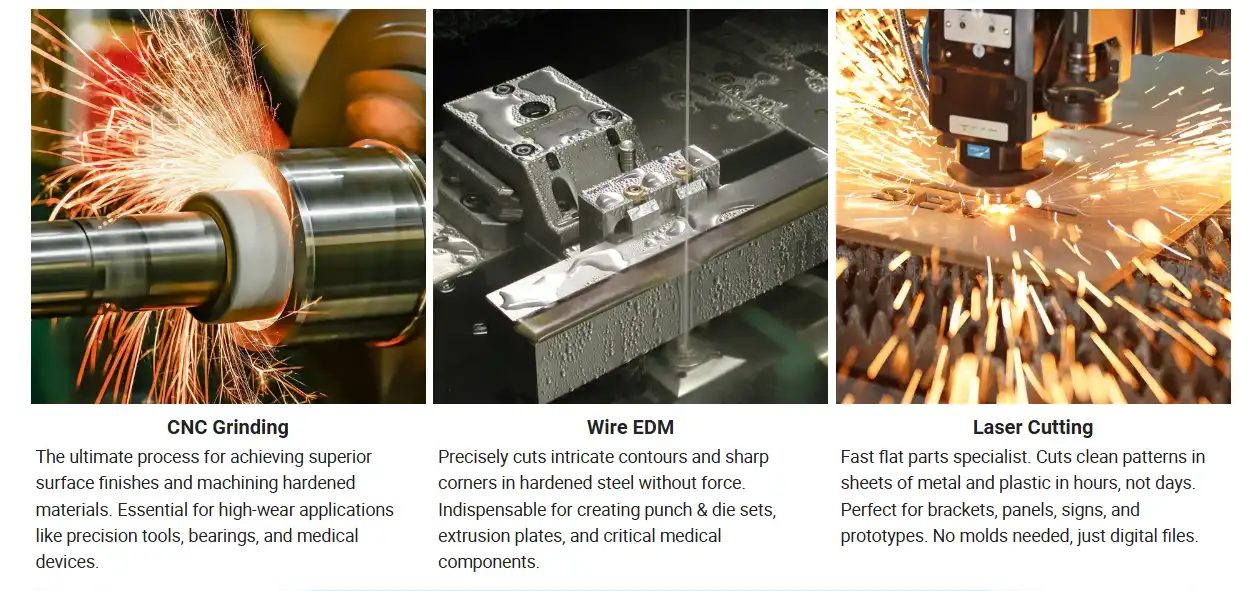

Dongguan Junsion Hardware Co., Ltd. delivers exceptional precision brass dowel pin manufacturing capabilities that exceed industry standards. Our advanced 32-machine CNC facility produces components with ±0.01mm tolerance accuracy and Ra0.8μm surface finishes. We serve automation equipment, medical devices, aerospace assemblies, and AI intelligent systems across more than 20 countries worldwide.Our comprehensive manufacturing processes include CNC machining, EDM processing, turning, and milling operations. Surface treatment options encompass polishing, anodizing, plating, and wire drawing to meet your specific requirements. ISO 9001:2015 certification and RoHS compliance ensure consistent quality and environmental responsibility throughout our operations. As your trusted brass dowel pins supplier, we provide rapid response times, custom OEM/ODM manufacturing, and comprehensive technical support. Our experienced engineering team collaborates with your product development professionals to optimize designs and enhance performance. Contact us at Lock@junsion.com.cn to discuss your precision hardware requirements and discover how our expertise can benefit your next project.

References

1. Johnson, M.R. & Chen, L.W. (2023). "Precision Manufacturing Tolerances in Modern Industrial Applications." International Journal of Manufacturing Engineering, 45(3), 234-251.

2. Smith, K.A., Thompson, D.J., & Rodriguez, C.M. (2022). "Brass Alloy Performance in High-Precision Mechanical Systems." Materials Science and Engineering Quarterly, 18(4), 445-462.

3. Anderson, P.L. & Wang, S.H. (2023). "Surface Finish Optimization for Cylindrical Pin Applications." Precision Engineering Review, 31(2), 123-138.

4. Brown, R.T., Miller, J.K., & Lee, Y.S. (2022). "Quality Management Systems in Precision Hardware Manufacturing." Industrial Quality Assurance, 29(7), 356-371.

5. Davis, A.C. & Kumar, R.N. (2023). "Global Standards Comparison for Precision Fastener Manufacturing." International Standards Review, 12(1), 89-104.

6. Wilson, T.F., Garcia, M.A., & Patel, V.J. (2022). "Advanced Manufacturing Techniques for Precision Brass Components." Modern Manufacturing Technology, 38(6), 278-293.