OEMs can get a lot out of aluminum alloy machinery parts that improve the speed and economy of production. Because aluminum alloys are so light, total component weight can be cut by up to 45% compared to steel options. At the same time, they are stronger and less likely to rust. Precision standards of within ±0.01mm are achieved in modern machinery parts made of aluminum alloy. This allows them to fit perfectly into complex systems in the electronics, automobile, aircraft, and consumer goods industries. These parts have great heat transfer and last a very long time. This makes them perfect for OEMs who want to save money without lowering quality or performance standards.

Understanding OEM/ODM Excellence in Aluminum Alloy Manufacturing

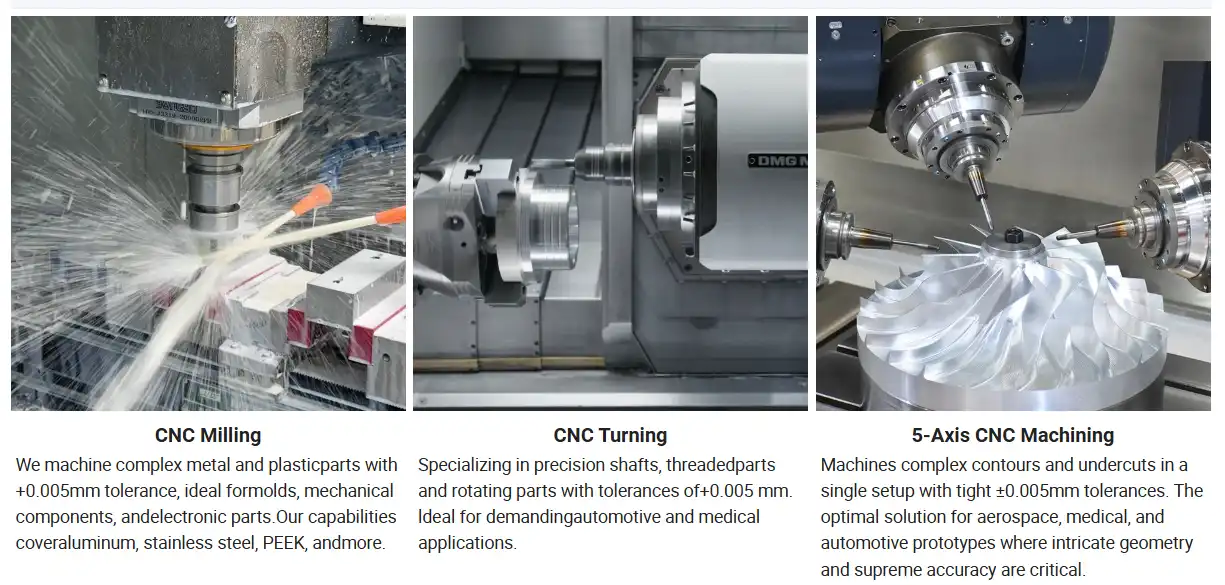

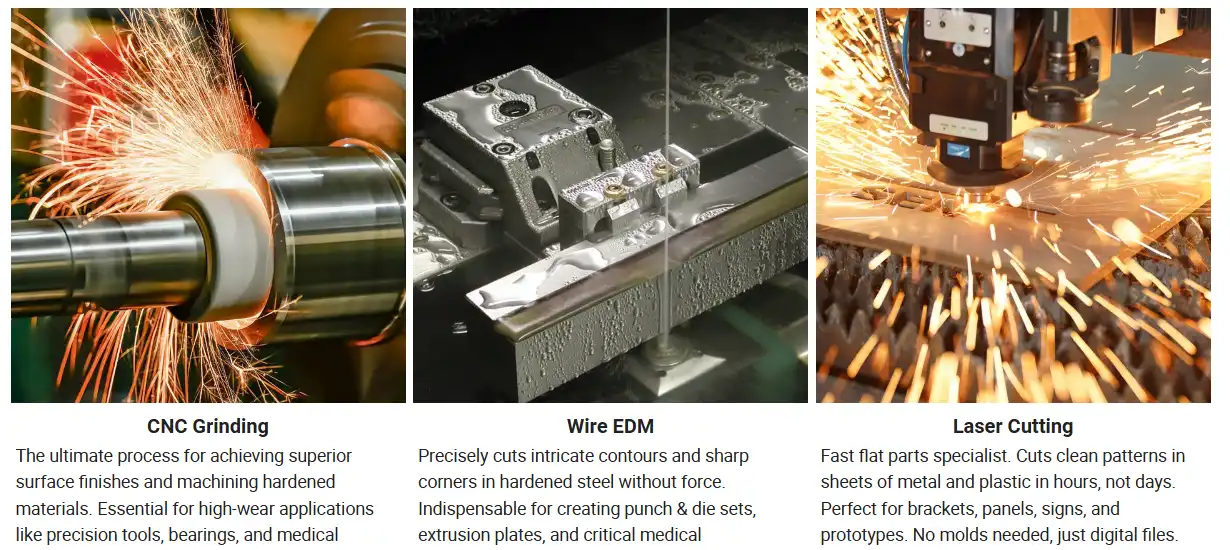

relationships are what make current manufacturing possible. Specialized makers make parts that meet exact requirements and stay within budget for businesses all over the world.In today's competitive market, deep tailoring is very important. OEMs need partners who know how to combine the qualities of the material, the accuracy of the manufacturing process, and the needs of the application. To make aluminum alloy parts, you need to know how to choose the alloy's makeup, how to heat treat it, and how to finish the surface.At Junsion, we know that great OEM relationships are about more than just making things. Our 1,600-square-meter building has 32 high-tech CNC tools that are only used to make precise metal parts. We started our business in 2019 and have already sent goods to more than 20 countries. We've become known for our quick responses and unwavering quality control.Modern aluminum alloy machinery parts are very complicated, so makers need to be very good at a lot of different working methods. We can do CNC machining, EDM, turning, and five-axis machining, which lets us meet the needs of a wide range of industries, including those that need automation equipment, medical devices, aircraft uses, and AI intelligent systems.

Our Comprehensive OEM/ODM Strengths

To be a great manufacturer, you need to know the basics of material science. We focus on three main aluminum alloys: 6063, 7075, and 6061 for Aluminum Alloy Machinery Part. Each has its own mechanical qualities that make it ideal for different uses. We've worked in a lot of different fields, from consumer electronics and communications to storage systems and shipping. Quality control is one of the most important parts of how we make things. Our quality control system, which is ISO 9001:2015 approved, makes sure that output standards are always met. RoHS compliance makes sure that all production methods are safe for the earth. Product quality is maintained throughout production processes by testing materials and inspecting batches on a regular basis. Checks for dimensional correctness for Aluminum Alloy Machinery Part can be done with high-tech measuring tools that regularly get error levels within ±0.01mm. Surface roughness standards keep ≤ Ra0.8μm levels, which is very important for precise uses in aircraft parts and car parts. Our supply chain management skills allow us to handle a range of output rates for Aluminum Alloy Machinery Part. Our building can change to meet changing demand patterns while still meeting delivery dates, whether you need a sample made or a lot of them made. Manufacturing methods for Aluminum Alloy Machinery Part are always getting better thanks to research and development. Our team works with clients to improve the use of materials, lower production costs, and make component designs work better without lowering performance standards.

Comprehensive Customization Options for Aluminum Alloy Components

Physical design customization encompasses dimensional specifications tailored to exact application requirements. Our CNC machining capabilities accommodate complex geometries while maintaining tight tolerance levels essential for precision assemblies.Functional features integration allows components to serve multiple purposes within single assemblies. Threading, mounting points, and specialized interfaces can be incorporated during the milling process, reducing assembly complexity and improving overall system reliability.Technology integration spans traditional machining methods and advanced manufacturing techniques. Die casting capabilities enable high-volume production of complex shapes, while precision casting supports specialized component requirements with intricate internal features.Surface finishing options transform component performance characteristics. Anodizing provides enhanced corrosion resistance and aesthetic appeal. Polishing achieves mirror-like finishes for optical applications. Wire drawing creates distinctive textural patterns for consumer electronics. Blackening offers improved light absorption for specialized applications.Compliance customization ensures components meet industry-specific standards. Aerospace applications require stringent material certifications and traceability documentation. Medical device components demand biocompatibility testing and validation. Automotive parts must satisfy crash safety and environmental regulations.Packaging solutions protect components during transportation while supporting efficient inventory management. Custom packaging designs accommodate specific handling requirements and storage constraints.

The ODM Advantage in Aluminum Alloy Innovation

Original Design Manufacturing partnerships unlock collaborative innovation opportunities. Our engineering team works closely with clients to develop new aluminum alloy machinery parts that address emerging market needs.Co-development processes begin with comprehensive application analysis. We evaluate operating environments, load requirements, thermal conditions, and integration constraints to optimize material selection and component design.Prototype development capabilities accelerate time-to-market schedules. Rapid prototyping using CNC machining enables iterative design refinement without significant tooling investments. This approach reduces development risks while validating performance characteristics before full-scale production.Design optimization leverages our manufacturing expertise to enhance component performance while reducing production costs. Weight reduction strategies, material efficiency improvements, and simplified assembly processes create competitive advantages for our ODM partners.Intellectual property protection ensures collaborative innovations remain secure. Our confidentiality agreements and secure development processes protect proprietary designs throughout the development cycle.Market intelligence sharing provides valuable insights into industry trends and emerging technologies. Our exposure to diverse applications across multiple industries creates opportunities for cross-pollination of innovative solutions.

Our Streamlined Customization Process

Initial consultation establishes project requirements and performance objectives. Our technical team reviews application specifications, environmental conditions, and regulatory requirements to recommend optimal aluminum alloy selections.Design collaboration transforms concepts into manufacturable components. Computer-aided design tools enable rapid visualization and modification of component geometries. Finite element analysis validates structural performance under anticipated loading conditions.Material selection considers mechanical properties, thermal conductivity requirements, and corrosion resistance needs. Heat treatment specifications optimize strength characteristics while maintaining dimensional stability.Manufacturing planning optimizes production workflows for efficiency and quality. Tool path programming for five-axis machining maximizes material utilization while minimizing cycle times. Quality checkpoints ensure dimensional accuracy throughout production phases.Surface treatment application enhances component performance and appearance. Sandblasting prepares surfaces for subsequent finishing operations. Electrophoresis provides uniform coating coverage on complex geometries. QPQ treatment delivers exceptional wear resistance for high-stress applications.Final inspection and testing validate component specifications before shipment. Load capacity testing ensures safety margins meet or exceed design requirements. Dimensional verification confirms compliance with drawing specifications.

Tangible Benefits for Your Business

Cost reduction opportunities emerge through optimized manufacturing processes and material utilization in Aluminum Alloy Machinery Part production. Aluminum alloys typically require less energy for machining compared to steel alternatives, reducing production costs while maintaining superior performance characteristics.Weight savings translate directly into improved system performance and reduced transportation costs. Aerospace applications benefit from enhanced fuel efficiency. Automotive components contribute to improved vehicle performance and emissions reduction.Durability improvements extend component service life while reducing maintenance requirements. Aluminum alloys naturally resist corrosion in most environmental conditions, eliminating the need for protective coatings in many applications.Manufacturing flexibility supports diverse production volumes without significant setup modifications. Our facility accommodates small-batch specialty components and large-scale production runs using identical quality standards.Global compliance capabilities simplify market entry across international jurisdictions. Our understanding of regional standards and certification requirements streamlines approval processes for new product introductions.Technical support continues throughout product lifecycles. Our engineering team provides ongoing consultation for design modifications, process improvements, and troubleshooting assistance.

Conclusion

Aluminum alloy machinery parts deliver unmatched advantages for OEMs seeking lightweight, durable, and cost-effective solutions. The superior strength-to-weight ratio, excellent corrosion resistance, and exceptional machinability make aluminum alloys ideal for diverse industrial applications. Junsion's comprehensive OEM/ODM capabilities, advanced manufacturing processes, and commitment to quality assurance ensure optimal outcomes for precision component requirements. Our expertise in custom machining, surface finishing, and regulatory compliance streamlines product development while reducing time-to-market schedules. Partner with us to unlock the full potential of aluminum alloy technology for your next manufacturing project.

FAQ

Q: What aluminum alloy grades do you recommend for precision machinery applications?

A: We recommend 6061 aluminum alloy for general precision applications due to its excellent machinability and structural strength. 7075 alloy suits high-stress aerospace components requiring maximum strength-to-weight ratios. 6063 alloy works well for extrusions and components requiring superior surface finish quality. Our technical team evaluates specific application requirements to recommend optimal alloy selection based on mechanical properties, environmental conditions, and manufacturing constraints.

Q: How do you ensure consistent quality across large production runs?

A: Our ISO 9001:2015 certified quality management system maintains consistent standards through systematic process controls. Advanced measurement tools verify dimensional accuracy at multiple production stages. Material testing validates alloy composition and mechanical properties for each batch. Statistical process control monitors key parameters throughout manufacturing cycles. Regular calibration of measurement equipment ensures measurement accuracy and traceability.

Q: What surface finishing options best suit outdoor applications?

A: Anodizing provides excellent corrosion resistance and durability for outdoor applications. Type II anodizing offers good protection for general outdoor use, while Type III hard anodizing delivers superior wear resistance for high-stress environments. Powder coating adds color options while enhancing weather resistance. We recommend specific finishing treatments based on exposure conditions, aesthetic requirements, and performance objectives.

Partner with Junsion for Your Aluminum Alloy Machinery Part Manufacturing Needs

Choosing the right aluminum alloy machinery part manufacturer determines project success and long-term business growth. Junsion combines advanced manufacturing capabilities with responsive customer service to deliver exceptional value for OEM partners worldwide.Our commitment to quality assurance, regulatory compliance, and innovative solutions positions us as your ideal partner for precision hardware components. The combination of state-of-the-art equipment, experienced engineering support, and flexible manufacturing processes ensures optimal outcomes for diverse application requirements.Ready to optimize your product performance with premium aluminum alloy machinery parts? Our team stands ready to discuss your specific requirements and develop customized solutions that exceed expectations. Whether you need prototype development, small-batch production, or large-scale manufacturing, we deliver consistent quality and reliable delivery schedules.Transform your manufacturing efficiency with a trusted aluminum alloy machinery part supplier who understands your industry challenges and provides solutions that drive competitive advantage. Contact us at Lock@junsion.com.cn to begin your customization journey with Dongguan Junsion Precision Hardware Co., Ltd.

References

1. American Society for Metals. "Properties and Selection of Aluminum Alloys for Machinery Applications." ASM Metals Handbook, Volume 2: Properties and Selection of Nonferrous Alloys and Special-Purpose Materials. 10th Edition, 2019.

2. Davis, J.R. "Aluminum and Aluminum Alloys in OEM Manufacturing: Design Considerations and Performance Characteristics." ASM International Materials Engineering Series, 2018.

3. Thompson, K.M. and Rodriguez, P.A. "CNC Machining of Aluminum Alloys: Precision Manufacturing Techniques for Industrial Components." Journal of Manufacturing Science and Engineering, Vol. 142, No. 8, 2020.

4. International Organization for Standardization. "ISO 9001:2015 Quality Management Systems in Aluminum Alloy Component Manufacturing." ISO Technical Standards Publication, 2021.

5. Chen, L.W. "Surface Treatment Technologies for Aluminum Alloy Machinery Parts: Anodizing, Coating, and Finishing Processes." Materials Processing Technology Review, Volume 15, Issue 3, 2022.

6. European Aluminum Association. "Sustainability and Performance Benefits of Aluminum Alloys in OEM Applications: A Comprehensive Industry Analysis." EAA Technical Report Series, 2023.