Sensor Accessories

Material: 316/304/303/410 stainless steel

Processing techniques: CNC, turning, five axis machining, stamping

Finish:Polishing, painting, anodizing,sandblasting, plating , electrophoresis

Application fields: Automation equipment,Vehicle,medical,aerospace, AI Intelligent ,home appliances, robots,

- Product Description

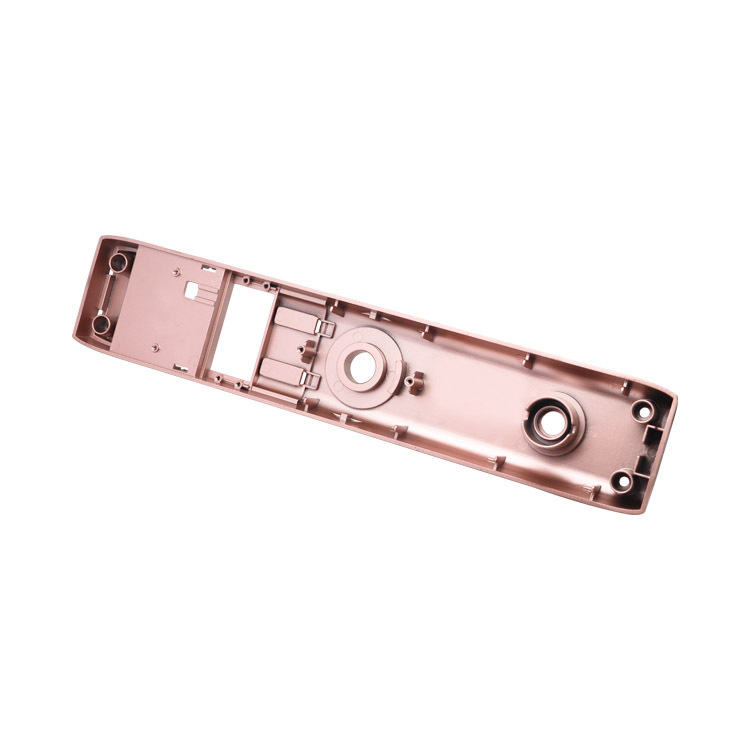

Sensor Accessories: Precision-Engineered Solutions for Optimal Performance

At Dongguan Junsion Precision Hardware Co., Ltd., we specialize in manufacturing high-quality Sensor Accessories that enhance the functionality and reliability of sensing systems across various industries. Our advanced precision machining capabilities and commitment to excellence make us a trusted supplier for businesses seeking top-tier sensor components. With our state-of-the-art facilities and experienced team, we deliver products that meet the most demanding specifications and quality standards.

Description

Our comprehensive range of the products includes:

- Sensor Housings: Durable enclosures designed to protect sensitive sensor components from environmental factors.

- Mounting Brackets: Precision-engineered brackets for secure and accurate sensor positioning.

- Connector Cables: High-quality cables ensuring reliable data transmission between sensors and control systems.

- Calibration Tools: Specialized equipment for maintaining sensor accuracy and performance.

- Signal Conditioners: Devices that optimize sensor output for improved signal quality and compatibility.

Each accessory is crafted with meticulous attention to detail, ensuring seamless integration with various sensor types and applications.

| Material | 1) Aluminum: AL 6061-T6, 6063, 7075-T etc. |

| 2) Stainless steel: 303,304,316L, 17-4(SUS630) etc. | |

| 3) Steel: 4140, Q235, Q345B,20#,45# etc. | |

| 4) Titanium: TA1,TA2/GR2, TA4/GR5, TC4, TC18 etc. | |

| 5) Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc. | |

| 5) Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc. | |

| Finish | Sandblasting, Anodize color, Blackenning, Zinc/Nickl Plating, Polish. |

| Power coating, Passivation PVD, Titanium Plating, Electrogalvanizing. | |

| Electroplating chromium, electrophoresis, QPQ(Quench-Polish-Quench). | |

| Electro Polishing,Chrome Plating, Knurl, Laser etch Logo, etc | |

| Main Equipment | STEP,STP,GIS,CAD,PDF,DWG,DXF etc or samples. |

| Tolerance | +/-0.01mm ~ +/-0.05mm |

| Surface roughness | Ra 0.1~3.2 |

| Inspection | Complete inspection lab with Micrometer, Optical Comparator, Caliper Vernier,CMM. |

| Depth Caliper Vernier, Universal Protractor, Clock Gauge, Internal Centigrade Gauge | |

| Capacity | CNC turning work range: φ0.5mm-φ150mm*300mm. |

| CNC milling work range: 510mm*1020mm*500mm. |

Surface Treatment

To enhance durability and performance, we offer multiple surface treatment options for our products:

- Anodizing: Provides corrosion resistance and aesthetic appeal for aluminum components.

- Electroplating: Improves conductivity and wear resistance for metal parts.

- Sandblasting: Creates a uniform matte finish and enhances adhesion for coatings.

- Brushing: Delivers a sleek, professional appearance for visible components.

Our surface treatments comply with RoHS standards, ensuring environmental safety and regulatory compliance.

Drawing Guide

We work closely with clients to bring their designs to life. Our engineering team can assist with:

- CAD file interpretation and optimization

- Material selection guidance based on application requirements

- Structural improvements for enhanced performance and manufacturability

- Custom design recommendations to meet specific sensor integration needs

Production Process

Our Sensor Accessories go through a rigorous production process:

- Material Selection: Choosing the optimal materials based on performance requirements.

- CNC Machining: Utilizing advanced equipment for precise component fabrication.

- Quality Inspection: Implementing strict in-process quality control measures.

- Surface Treatment: Applying specified finishes for enhanced durability and functionality.

- Assembly: Carefully assembling components to ensure proper fit and function.

- Final Testing: Conducting comprehensive quality checks before packaging.

Quality Certification

We maintain the highest quality standards for our products:

- ISO 9001:2015 certified quality management system

- RoHS compliance for all materials and processes

- Regular third-party audits and certifications

- Comprehensive documentation and traceability

Shipping and Delivery

Our efficient logistics network ensures timely delivery of your products:

- Sample delivery within 3 days

- Mass production orders shipped within 7-15 days

- Flexible shipping options to meet urgent requirements

- Secure packaging to prevent damage during transit

Why Choose Us?

- Expertise: Over a decade of experience in precision metal fabrication.

- Customization: Tailored solutions to meet your specific sensor accessory needs.

- Quality Assurance: Rigorous quality control throughout the production process.

- Fast Turnaround: Efficient production and delivery to support your project timelines.

- Global Reach: Serving 500+ satisfied clients worldwide.

- Technical Support: Expert guidance on material selection and design optimization.

FAQ

Q: What is the minimum order quantity for the products?

A: Our MOQ varies depending on the specific accessory and customization requirements. Please contact us for details.

Q: Can you provide custom designs for the products?

A: Yes, we offer custom design and manufacturing services tailored to your unique specifications.

Q: What materials do you use for the products?

A: We work with various metals including stainless steel, aluminum, copper, and titanium, depending on the application requirements.

Q: How do you ensure the quality of your products?

A: We implement a strict quality control system, including IQC, IPQC, and OQC, using advanced testing equipment to meet international standards.

Contact & Support

Ready to elevate your sensing solutions with our premium Sensor Accessories? Contact our expert team today for personalized assistance and quotations.

Email: Lock@junsion.com.cn, echo@junsion.com.cn, or evelyn@junsion.com.cn.

Trust Dongguan Junsion Precision Hardware Co., Ltd. for all your sensor accessory needs. Let's collaborate to enhance your sensing capabilities and drive innovation in your industry.

_1755501595589.jpg)

_1755504107727.jpg)