To order unique motorbike parts from Asia, you need to plan ahead and carefully choose which vendors to work with. The area is great for manufacturing and has reasonable prices, but to be successful, you need to know about quality standards, contact methods, and shipping times. When you work with experienced makers who specialize in custom motorbike spare parts, you can be sure that you will get precisely made parts that meet your exact needs at a low cost.

Understanding the Asian Motorcycle Parts Manufacturing Landscape

Asia makes most of the motorbike parts in the world—over 60% of all parts made in the world are made there. The region's success is due to a number of important factors that make it a desirable place to buy handmade motorbike parts.In the last twenty years, the machinery for making things in places like China and Taiwan has changed a lot. CNC machine centers, precise casting equipment, and high-tech quality control systems are now commonplace in modern facilities. Asian companies can now make parts with margins as small as ±0.01mm thanks to these investments in technology. These parts meet the strict standards needed for high-performance motorcycle uses.When buying from Asia, cost-effectiveness is still a big draw. Because of cheaper labor, easier access to raw materials, and economies of scale, prices can be 30 to 50 percent lower than in the West. The cheapest price doesn't always mean the best deal, though. To be successful at buying, you need to find a balance between cost, quality, service efficiency, and the chance to build a long-term relationship.Integration of the supply line is another big benefit. Asian producers usually already have connections with companies that supply materials, do finishing, and handle shipping. This connection can make it easier to buy things and cut down on the time it takes to get complex special parts.

Essential Selection Criteria for Asian Suppliers

Picking the right manufacturing partner is very important for getting unique Custom Motorcycle Spare parts that work. Your review should include a number of things that have a direct effect on the quality of the product, the speed of delivery, and the general success of the project. Manufacturing skills are the most important part of evaluating a provider. Look for places that have modern CNC machines, EDM machines, and multi-axis cutting centers. Advanced makers should offer a full range of services, such as cutting, turning, grinding, and finishing. For motorcycle uses, it's important to be able to work with a variety of materials, including aluminum alloys, stainless steel, titanium, and high-performance plastics. Quality badges show how committed a seller is to doing a great job. ISO 9001:2015 certification shows that quality management systems have been in place for a while, while industry-specific certifications like TS 16949 show that quality standards are up to par for the automotive industry. RoHS approval makes sure that your Custom Motorcycle Spare parts are safe for use around the world and don't harm the environment. Good communication skills can make or break your buying experience. For providers to be effective, they need to have expert workers who can speak English and understand engineering sketches, material specs, and tolerance requirements. Inquiries should be answered within 24 hours, and project reports should be sent out on a frequent basis. When planning for growth, production capacity and scale are important. Check with possible providers to see if they can meet your current Custom Motorcycle Spare number needs and plan for future growth. Companies that are flexible and can respond quickly to changing needs or pressing delivery requirements are very valuable to businesses that are always changing.

Top Custom Motorcycle Spare Categories to Source from Asia

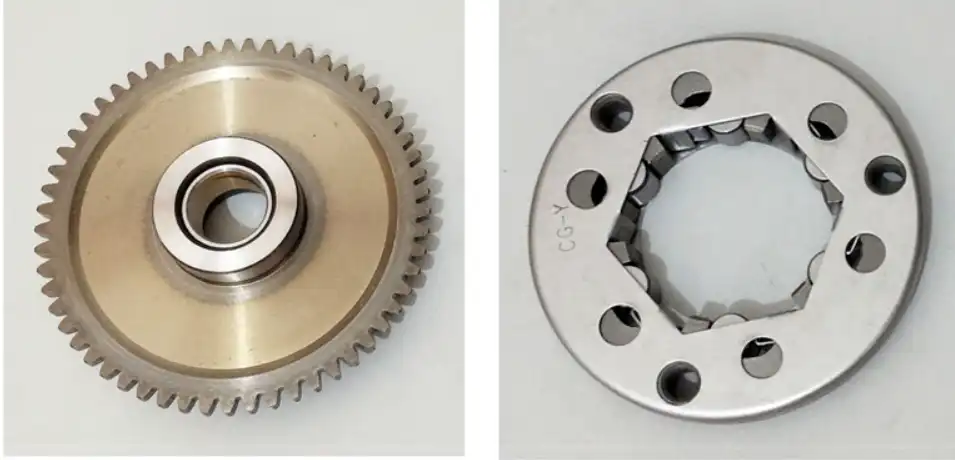

Precision Engine Components

Asian makers are great at making special engine parts that need to be very precise and last a long time. These parts are very important to the performance of a motorbike and must be made to the highest standards. Custom pistons are a popular area where Asian suppliers show they can do amazing things. With modern CNC cutting, it is possible to get exact hole sizes, ring groove specs, and skirt shapes that make engines run better. Manufacturers can work with different metal alloys and add special finishes to make the parts last longer and be more resistant to heat. Cylinder heads are a great example of how advanced Asian manufacturing can be. Multiple grinding steps, accurate valve seat cutting, and close attention to the combustion chamber shape are needed to make these complicated parts. Advanced factories can make heads with built-in cooling channels, custom port layouts, and unique fitting holes. Asian casting and precision machining skills help with connecting rods. Manufacturers can make rods with specific length-to-weight ratios, beam shapes, and weight limits. To make sure that engines work perfectly together, good providers use high-tech balance equipment. Crankshafts are the most precise parts of an engine and need the most advanced tools and strict quality control. Custom crankshafts with different stroke lengths, journal sizes, and balance arrangements can be made by Asian sources. Heat cleaning methods make sure that the power and longevity are at their best.

Custom Body and Frame Components

A big part of the market for unique body parts and frame changes is driven by people wanting to look different. These eye-catching parts can be made by a wide range of Asian makers. Custom fuel tanks are a great example of the artistic and technical skills that Asian providers can offer. These parts need to be formed in complicated ways, welded with great care, and finished by experts. Manufacturers can make tanks with custom forms, built-in fixing holes, and the exact capacity needed. Asian experts in tube bending, welding, and precise cutting can help with frame changes and custom subframes. Advanced laser cutting equipment allows complex patterns and perfect fit limits. Powder painting and other specialized finishing services make surfaces last longer and look better. Precision making is shown in the swing arms and suspension components. For these safety-important parts to work, they need to be made with exact specs, the best materials, and strict testing procedures. Asian manufacturers can make custom swing arms with unique shapes, built-in fixing points, and special materials. Furthermore, Asian manufacturers can make body panels in a huge range of ways. Skilled makers can take design ideas and turn them into parts that are ready for production, like carbon fiber fairings and metal side panels. Modern shaping methods make it possible to make complicated forms and features that fit together.

Performance Exhaust Systems

Asian suppliers can show how good they are at tube bending, welding, and sound engineering by making custom motorcycle spare exhaust systems. Header pipes need to be carefully bent to make the exhaust flow best while still allowing for enough ground clearance and mounting options. Asian makers use mandrel bending methods that keep the internal width consistent and reduce flow limits. Advanced sound engineering and precise manufacturing help muffler systems work better. Suppliers can make unique internal shield designs, use sound-absorbing materials, and put on special finishes that are resistant to heat and last a long time. Asian makers' full range of skills is shown by complete system integration. Multiple production methods need to work together on these projects, and they need to be tested for fit and function in great detail.

Navigating Quality Standards and Compliance

Making sure the quality is good is an important part of getting handmade motorbike parts from Asia. Quality rules that you understand and follow will protect your investment and make sure that your customers are happy. Material approval is the best place to start when you want to validate quality. Reliable sources give mill certificates for all raw materials that show what chemicals are in them, how they work, and how they were heated. This paperwork makes it possible to track down parts and makes sure they meet the requirements. Different providers have different checking methods for dimensions, but quality-conscious makers use coordinate measuring machines (CMM) and other accurate tools. Ask for inspection reports that list important dimensions and standards, especially for safety-critical parts like brake parts or steering systems. Pay close attention to surface finish specs, especially for parts that move or look good. Grinding, sanding, and special finishing methods used by Asian providers can make the surface look great. Use standard roughness measures, such as Ra values, to set clear requirements. Testing and approval methods should be in line with the needs of your particular application. Performance testing for engine parts, load testing for structure parts, and wear testing for high-stress uses are all important ways to make sure the quality of a product.

Managing Communication and Project Timelines

To successfully buy handmade motorbike parts from Asian sources, you need to be able to communicate clearly. Misunderstandings can be avoided by setting clear goals and keeping everyone up to date on a daily basis. Technical documents should be complete and easy to understand. Give full engineering plans with all the necessary measurements, material details, and finish needs. For complex shapes, 3D models can be used along with 2D drawings to help with understanding, which lowers the chance of mistakes. Setting project milestones helps keep everyone on track and manage expectations. Set clear due dates for sending in the sample, getting approvals, and finishing production. Schedule extra time to account for possible delays or changes. Projects stay on track with regular contact procedures. Weekly status reports, photos of work in progress, and quick answers to technical questions all show that the connection between the buyer and the seller is professional.

Cost Optimization Strategies

When buying custom motorbike parts, you need to think strategically about more than just prices to get the best deal. To get the most out of your buying investment, you should know about total cost of ownership and value-added services. When it comes to custom motorcycle spare, volume has a big effect on unit price. Many Asian sellers offer good discounts for buying in bulk, but the minimum order amounts depend on how complicated the item is and how much it costs to set up. Getting better prices can be done by combining orders from different projects. Design optimization can lower the cost of making something without lowering its quality. During the planning part, work with your sources to find ways to save money. You can save a lot of money by making cutting processes easier, fixing hole sizes, and making the best use of materials. The total cost of your purchases is affected by the terms of payment and the currency used. Many Asian sellers will lower your prices if you pay in advance or send a letter of credit. For big orders, currency hedge techniques can protect you from changes in the exchange rate.

Building Long-Term Supplier Relationships

Building strong, long-lasting relationships with Asian makers is key to getting unique motorbike spare parts that work well. These connections give businesses an edge over their competitors and, over time, make projects better.Partners trust and understand each other more when they talk to each other regularly. When possible, regular trips to the plant show loyalty and give information about how things are made. Video conference calls can be used instead of face-to-face talks to keep human ties.Collaborative growth projects show how smart partnerships can work. Working together to create a new product takes advantage of the knowledge of suppliers and makes everyone invested in the project's success. These partnerships often produce new ideas and give businesses an edge over their competitors.Giving providers feedback on their work shows that you value the connection and helps them improve their services. Offer helpful comments on the quality, delivery, and sharing of your work. Recognize outstanding work to encourage good behavior.

Technology Integration and Digital Tools

Digital tools and integrating technology into modern buying methods help when dealing with Asian sellers. These tools make things faster, less messy, and easier for people to work together on.CAD file sharing tools make it easy for designers to work together and keep track of changes. Cloud-based systems let you see the most up-to-date plans and specs at any time. This makes version control problems less likely, which can prevent mistakes in manufacturing.Software for managing projects helps complicated custom parts projects with many parties run smoothly. These tools let you see the state of a project, keep track of milestones, and see a past of communications.Quality paperwork tools make it easier to report inspections and keep track of certificates. Digital platforms can store and organize quality records, making them simple to find when needed for future reference or audits.

Conclusion

You can get custom motorcycle parts from Asia, but you need to plan ahead, do a full background check on the seller, and make sure you understand how to communicate clearly. Custom Motorcycle Spare production companies and motorcyclists alike are drawn to the area because it has cheap prices, a lot of customization choices, and the best production facilities in the world. Businesses will benefit in the long run from building strong relationships with providers who care about quality. You can get great results while cutting costs and speeding up delivery times if you follow these best practices and work with experienced makers who know what you need. To be successful, you need to find the best mix between cost, quality, connection, and reliability. Check out potential partners carefully, be clear about what you need, and keep the lines of communication open during the tasks. We can expect better products, faster wait times, and happy customers if we spend money on good ways to buy things.

Partner with Junsion for Your Custom Motorcycle Spare Manufacturing Needs

Dongguan Junsion Hardware Co., Ltd. stands ready to support your custom motorcycle spare manufacturing requirements with precision, reliability, and exceptional service. Our state-of-the-art facility houses 32 advanced CNC machines capable of achieving tolerances of ±0.01mm and surface finishes of Ra0.8μm or better.Our comprehensive manufacturing capabilities encompass all essential processes for motorcycle components. From precision CNC machining and five-axis operations to specialized finishing services including anodizing, plating, and QPQ treatments, we deliver complete solutions for your custom motorcycle spare projects. We work with diverse materials including aluminum alloys, stainless steel, brass, and high-performance plastics to meet your specific requirements. Ready to experience the advantages of working with a trusted manufacturing partner? Contact us at Lock@junsion.com.cn to discuss your custom motorcycle spare requirements and discover how our expertise can accelerate your next project.