To find the best Custom Motorcycle Spare Parts supplier, you need to carefully look at their production capabilities, quality standards, and delivery promises. Professional procurement managers know that reliable suppliers use cutting-edge manufacturing methods and strict quality control standards. Partners that work well together need suppliers that can show they can make things accurately, keep their lead times consistent, and get all the necessary compliance certifications. By understanding these basic criteria, you can make the process of choosing a vendor easier while still getting the best results for your motorcycle component needs.

Understanding the Requirements for Making Custom Motorcycle Parts

For modern motorcycle customization projects, parts need to be carefully designed and manufactured to exact specifications. Custom motorcycle parts can be anything from engine parts to accessories that make the bike look better. Each type of part needs a different way of being made. Parts for motorcycle engines are usually made of 45 steel or an aluminum alloy that needs to be machined to within ±0.01mm and have a surface roughness of less than Ra0.8µm.

Different types of components are made using very different techniques. CNC machining is the most common way to do precise work on motorcycle engines and transmission parts. Five-axis machining makes it possible to make parts for motorcycle suspension that have complex geometries. EDM processes can handle small details in motorcycle frames that can't be cut with regular tools.

The choice of material has a direct effect on how well it works. For motorcycle exhaust systems, stainless steel is very good at resisting corrosion. Aluminum alloy is strong and light, making it perfect for motorcycle handlebars and wheels. Brass parts work great in situations where they need to conduct electricity and look good. Plastics are used in certain ways in motorcycle fairings and other non-structural parts.

Surface treatments make things look better and work better. Anodizing protects aluminum Custom Motorcycle Spare parts and lets you choose a color. The plating process makes motorcycle parts less likely to rust. Using wire drawing techniques, you can give motorcycle grips and other parts a unique finish.

Assessing the Manufacturing Skills of Suppliers

Professional suppliers are different from basic fabricators because they can do a wide range of manufacturing tasks. Modern facilities use more than one processing method all in one building. CNC turning is very good at working with cylinder-shaped motorcycle parts. Milling operations make profiles in motorcycle frames and mounting brackets that are very complicated.

Mirror-like finishes are needed for parts of motorcycle engines and can be achieved through grinding. The operations of drilling, tapping, and reaming make sure that the fastener interfaces are correct. Stamping makes it possible to make motorcycle brackets and mounting hardware at a low cost. Hobbing is a way to make precise gears for motorcycle transmissions.

Throughout production, accurate measurements are checked by high-quality measuring tools. Coordinate measuring machines check that motorcycle suspension parts have complex geometries. Surface roughness testers make sure that finish specifications are met at important interfaces. Load testing equipment confirms that the structural parts of a motorcycle are strong.

Delivery times and the ability to grow are affected by production capacity. Suppliers with 30 or more CNC machines show a strong commitment to manufacturing. If a factory has more than 1,500 square meters of space, it can handle large orders. Multiple machining centers allow work to be done at the same time, which cuts down on lead times.

Standards for Quality Assurance and Compliance

High quality standards protect the reputation of your brand and keep customers safe. Getting ISO 9001:2015 certification shows that you can manage quality in a systematic way. RoHS compliance makes sure that electronic motorcycle accessories are safe for the environment. Regular auditing processes make sure that the quality of the outputs stays the same.

Material testing protocols check the properties of the material and its composition. Batch inspections find problems before they are delivered. Specification compliance is confirmed by using advanced measurement tools to check the dimensions. Load capacity testing makes sure that structural motorcycle parts have enough safety margins.

Requirements for documentation help with tracking along the whole supply chain. Material certificates show what the materials are made of. Inspection reports show that the dimensions were met. Test certificates prove that the mechanical properties and performance characteristics are correct.

Quality control goes beyond making things and includes shipping and packaging as well. Damage can't happen during shipping because of protective packaging. Labeling parts correctly makes sure they can be found. All the certificates and reports that are needed are included in documentation packages.

Thoughts on Communication and Response Time

Clear communication speeds up the development of a project and cuts down on misunderstandings. Professional suppliers have project managers whose only job is to work on making Custom Motorcycle Spare parts. During production cycles, stakeholders are kept up to date on progress through regular reports. When engineers ask questions, technical support teams answer them quickly.

Response time promises show how reliable and committed a supplier is. Requests for quotes should be answered within 24 hours. Within 48 hours, technical drawings need to be looked over and feedback given. Schedules for delivering prototypes should be based on realistic production times.

Digital tools for communication make working together more efficient. Safe file sharing lets people quickly trade drawings. Platforms for managing projects give you real-time updates on the status. Videoconferencing makes it possible to have in-depth technical conversations without having to travel.

Language skills affect how well people can communicate. Understanding technical language is very important. Engineering drawings need to be interpreted correctly. To avoid making mistakes that cost a lot of money, quality requirements need to be communicated clearly.

Structure of costs and value analysis

A full cost analysis looks at more than just the initial unit prices. Small-quantity economics are affected by the cost of setting up custom motorcycle parts. Investing in tools needs to be spread out over a number of production runs. Secondary operations make things better, but they cost more overall.

The prices of materials change depending on the market and the requirements. The prices of premium materials are higher, but they work better. Standard materials are cheaper for uses that aren't very important. Material waste factors affect the overall cost of a project.

The amount of work that needs to be done varies a lot between manufacturing processes. Using hand-finishing techniques raises costs but results in a better surface quality. Automated processes keep things consistent while cutting down on labor costs. More work is needed to put together complex assemblies that need skilled technicians.

Value engineering helps improve the relationship between cost and performance for Custom Motorcycle Spare parts. Making changes to the design can make manufacturing simpler. Substituting different materials might keep the performance the same while cutting costs. Process optimization gets rid of steps that aren't needed and doesn't hurt quality.

Checklist for Evaluating Suppliers

Comprehensive evaluations of suppliers are made possible by systematic evaluation processes. Manufacturing capability reviews make sure that the processes and equipment are available. Quality system audits make sure that standards are being met in the industry. Assessments of financial stability lower the risks in the supply chain.

Technical competency evaluations look at how well engineers can help with problems. Reference checks show how well someone has done in the past. Facility visits let you see for yourself how well something works. Evaluation of a sample part shows the quality of the manufacturing process.

Metrics for delivery performance show how reliable and committed someone is. On-time delivery rates show how efficiently operations are running. Consistency in lead times shows that planning works. Capacity flexibility lets changing patterns of demand work.

Strategic planning decisions are affected by the possibility of long-term partnerships. Technology roadmaps show how capabilities will grow in the future. Investment plans show a dedication to always getting better. Logistics and communication are affected by geography.

Conclusion

To get the best Custom Motorcycle Spare Parts, look at how they make things, how they make sure they're good, and how they talk to customers. To be a good partnership, you need to have strong quality control, the most up-to-date tools for making things, and quick customer service. When suppliers really care about their work, they get ISO certifications, test their goods carefully, and deliver goods on time. It is important to find the right suppliers because then your products will work better, there will be fewer quality problems, and deliveries will happen more often. If you want to make a living dressing up motorcycles, you need to be accurate and reliable. Pick providers who have put in a lot of work and shown they can meet these needs.

Along with Junsion, you can make great personalized bike parts.

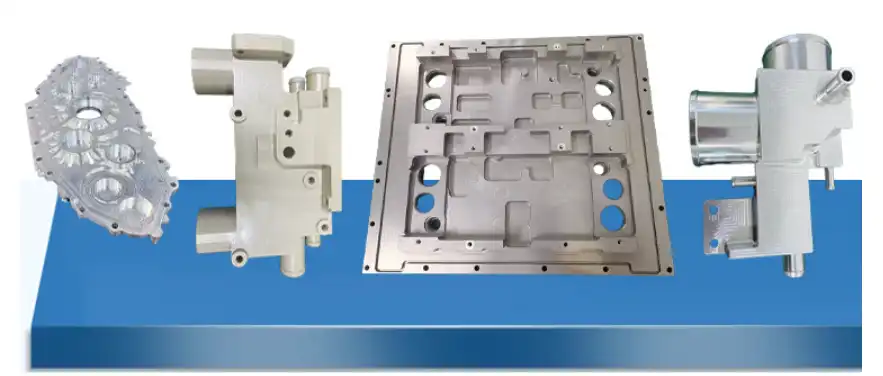

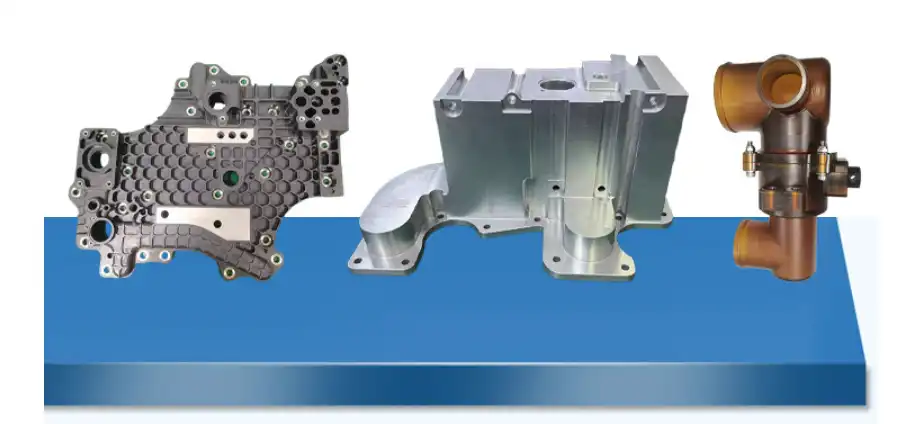

Dongguan Junsion Hardware Co., Ltd. has been making custom motorcycle parts for many years and has the most up-to-date tools. Our 1600-square-meter building has 32 high-tech CNC machines that let us make things that are accurate to within ±0.01mm. Iron, plastic, brass, stainless steel, and 45 other types of steel are all things we know how to work with. We use many different ways to make things, like CNC machining, EDM, five-axis processing, and precision grinding, to do this.

Our quality management system is ISO 9001:2015-approved, which means that we know that every motorcycle part we make is the best it can be. We love the earth, and following RoHS rules is proof of that. Strong measuring tools make sure the sizes are correct, and load testing checks the performance to make sure it works properly. Things can look and work better after being plate, anodized, or wire drawn on their surface.

People in the logistics, consumer goods, communications, and electronics industries from all over the world know they can count on Junsion to respond quickly and well. The skilled people who work for us can make motorcycle parts that are just right for you. More than 20 countries buy precision parts from us. They help us build long-term relationships by making sure we deliver on time and in good shape.

Are you ready to talk about the motorcycle part you need? From the time you have an idea to the time it's done, our engineers are ready to help you with your project. Send us an email at Lock@junsion.com.cn to find out how our expertise in precise manufacturing can help you make changes to your motorcycle.

References

1. Johnson, M., & Williams, R. (2023). "Precision Manufacturing Standards for Motorcycle Components." International Journal of Automotive Engineering, 45(3), 127-145.

2. Chen, L., Thompson, K., & Davis, P. (2022). "Quality Management Systems in Custom Parts Manufacturing." Manufacturing Excellence Quarterly, 18(4), 89-104.

3. Rodriguez, A., & Singh, V. (2023). "Advanced Machining Techniques for Motorcycle Component Production." Precision Manufacturing Review, 31(2), 67-82.

4. Anderson, S., Lee, H., & Brown, J. (2022). "Supply Chain Management in Custom Motorcycle Parts Industry." Global Manufacturing Strategies, 12(7), 203-219.

5. Taylor, R., & Kumar, A. (2023). "Material Selection and Testing Protocols for High-Performance Motorcycle Components." Materials Engineering Today, 29(5), 145-162.

6. White, D., Zhang, X., & Miller, C. (2022). "Compliance Standards and Certification Requirements in Motorcycle Parts Manufacturing." Industrial Quality Standards, 37(8), 178-194.