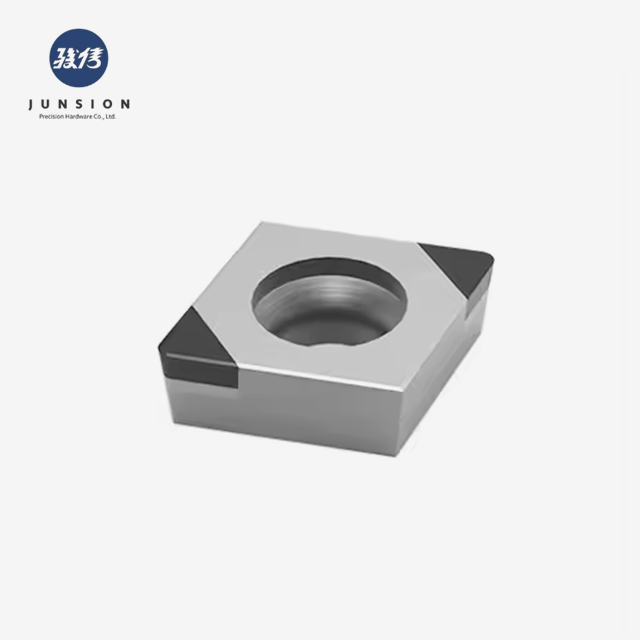

Turning Inserts

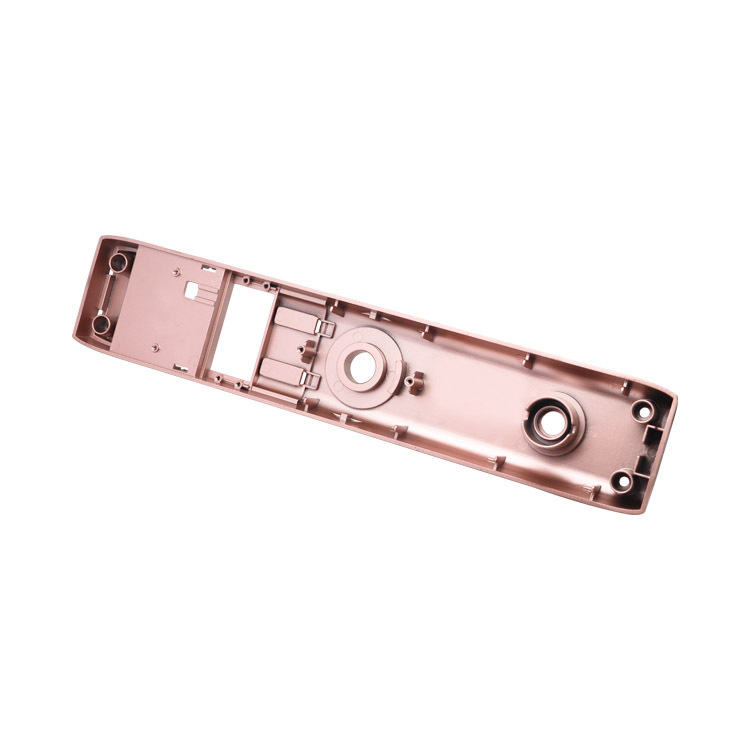

Material: 316/304/303/410 stainless steel

Processing techniques: CNC, turning, five axis machining

Finish:Polishing, painting, anodizing,sandblasting, plating , electrophoresis

Application fields: Automation equipment,Vehicle,medical,aerospace, AI Intelligent ,home appliances, robots,

- Product Description

Turning Inserts: Precision Engineering Solutions for High-Performance Machining

At Dongguan Junsion Precision Hardware Co., Ltd., we're your trusted manufacturer and supplier of high-quality turning inserts. We stand out in the business because of our advanced precision machining skills and dedication to quality. We carry a lot of products that are made to meet the specific needs of many types of manufacturing, such as aerospace, automotive, and precision engineering.

Description

Our premium products are engineered for superior performance and longevity. These cutting tools are essential for efficient metal removal in turning operations, offering:

- Exceptional edge strength and wear resistance

- Precise geometry for optimal chip control

- Compatibility with various materials, including stainless steel, aluminum, and titanium

- Consistent quality for repeatable results

We offer a comprehensive selection of insert shapes, including:

- Diamond (55°)

- Triangle (60°)

- Square (90°)

- Round

- Hexagonal (80°)

Each shape is designed for specific applications, ensuring you have the right tool for every job.

| Material | 1) Aluminum: AL 6061-T6, 6063, 7075-T etc. |

| 2) Stainless steel: 303,304,316L, 17-4(SUS630) etc. | |

| 3) Steel: 4140, Q235, Q345B,20#,45# etc. | |

| 4) Titanium: TA1,TA2/GR2, TA4/GR5, TC4, TC18 etc. | |

| 5) Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc. | |

| 5) Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc. | |

| Finish | Sandblasting, Anodize color, Blackenning, Zinc/Nickl Plating, Polish. |

| Power coating, Passivation PVD, Titanium Plating, Electrogalvanizing. | |

| Electroplating chromium, electrophoresis, QPQ(Quench-Polish-Quench). | |

| Electro Polishing,Chrome Plating, Knurl, Laser etch Logo, etc | |

| Main Equipment | STEP,STP,GIS,CAD,PDF,DWG,DXF etc or samples. |

| Tolerance | +/-0.01mm ~ +/-0.05mm |

| Surface roughness | Ra 0.1~3.2 |

| Inspection | Complete inspection lab with Micrometer, Optical Comparator, Caliper Vernier,CMM. |

| Depth Caliper Vernier, Universal Protractor, Clock Gauge, Internal Centigrade Gauge | |

| Capacity | CNC turning work range: φ0.5mm-φ150mm*300mm. |

| CNC milling work range: 510mm*1020mm*500mm. |

Surface Treatment

To enhance the performance and lifespan of our products, we apply advanced surface treatments, including:

- PVD (Physical Vapor Deposition) coating

- CVD (Chemical Vapor Deposition) coating

- AlTiN coating for high-temperature applications

- TiCN coating for improved wear resistance

These treatments significantly improve hardness, reduce friction, and extend tool life, leading to increased productivity and cost savings for your operations.

Drawing Guide

We understand the importance of precision in your manufacturing processes. That's why we offer a comprehensive drawing guide for our products. This guide includes:

- Detailed dimensional specifications

- Tolerance information

- Geometry and clearance angles

- Chip breaker designs

Our technical team is always available to assist you in selecting the right insert based on your specific requirements and application needs.

Production Process

Our state-of-the-art production process ensures the highest quality turning inserts:

- Material selection: We use premium-grade carbide substrates for optimal performance.

- Pressing: Precision pressing to achieve the desired shape and size.

- Sintering: High-temperature sintering for enhanced strength and density.

- Grinding: Multi-axis CNC grinding for precise edge geometry.

- Coating: Application of advanced surface treatments.

- Quality control: Rigorous inspection using 2.5D projectors and other advanced testing equipment.

Quality Certification

We adhere to strict quality control standards throughout our production process. Our products meet or exceed international standards, including:

- ISO 9001:2015 Quality Management System

- ISO 14001:2015 Environmental Management System

- RoHS compliance for environmental safety

Each batch of inserts undergoes thorough testing to ensure consistent performance and reliability.

Shipping and Delivery

We understand the importance of timely delivery in maintaining your production schedules. Our efficient logistics network allows us to offer:

- Sample delivery within 3 days

- Mass production orders within 7-15 days

- Flexible shipping options to meet your specific needs

- Secure packaging to ensure safe arrival of your products

Why Choose Us?

- Advanced precision machining capabilities

- Wide material selection and consistent quality

- Customization options to meet your specific requirements

- Fast turnaround times and reliable delivery

- Strict quality control system

- Extensive industry experience and global reach

- Customer-centric service and technical support

FAQ

Q: What materials can your products machine?

A: Our inserts are suitable for a wide range of materials, including stainless steel, aluminum, titanium, and various alloys.

Q: Do you offer custom turning insert solutions?

A: Yes, we provide tailored solutions based on your drawings or samples, including material selection and structural optimization.

Q: What is the minimum order quantity for the products?

A: We offer flexible order quantities to accommodate both small and large-scale production needs. Contact us for specific details.

Q: How do I choose the right turning insert for my application?

A: Our technical team can assist you in selecting the optimal insert based on your machining parameters, material, and desired finish.

Contact & Support

Ready to elevate your machining capabilities with our high-performance turning inserts? Contact our expert team today for personalized assistance and quotations.

Email: Lock@junsion.com.cn, echo@junsion.com.cn, or evelyn@junsion.com.cn.

Trust Dongguan Junsion Precision Hardware Co., Ltd. for all your turning insert needs. Experience the difference that precision, quality, and reliability can make in your manufacturing processes.

_1755501421989.jpg)