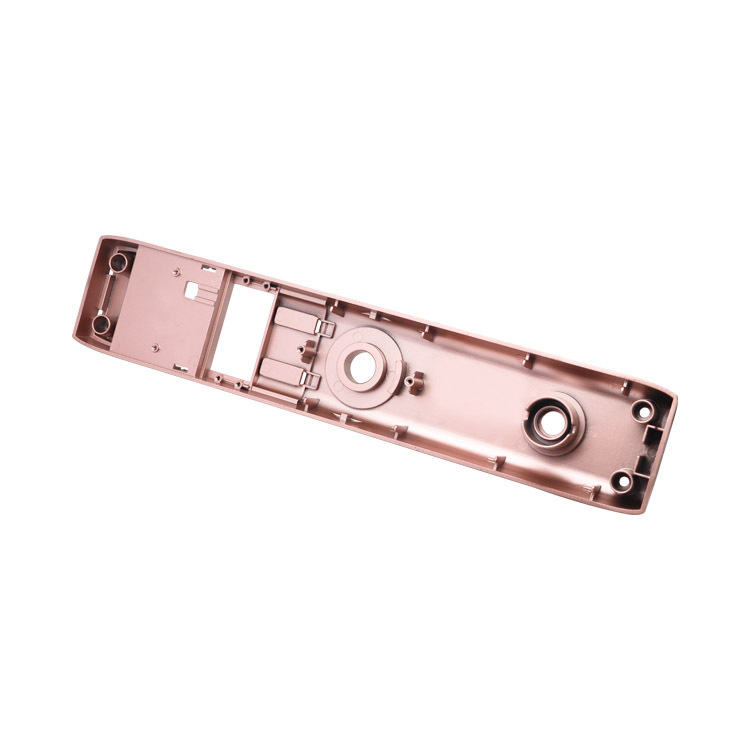

Insert Parts

Material: 316/304/303/410 stainless steel

Processing techniques: CNC, turning, five axis machining, stamping

Finish:Polishing, painting, anodizing,sandblasting, plating , electrophoresis

Application fields: Automation equipment,Vehicle,medical,aerospace, AI Intelligent ,home appliances, robots,

- Product Description

Insert Parts: Precision Solutions for Industrial Applications

At Dongguan Junsion Precision Hardware Co., Ltd., we specialize in manufacturing high-quality Insert Parts for various industries. We are a leading supplier of the products because of our dedication to excellence and sophisticated precision machining capabilities. We consistently provide accuracy and dependability for even the most intricate components, with tolerances as high as ±0.01mm.

_1755501421989.jpg)

_1755742565833.jpg)

_1755501421843.jpg)

Description

Our products are designed to offer dependable and safe connections for a variety of uses. These finely manufactured parts offer increased strength and load-bearing capacity because they are made to be threaded or inserted into softer materials. To meet your unique demands, we offer a range of sizes, materials, and styles for our products.

| Material | 1) Aluminum: AL 6061-T6, 6063, 7075-T etc. |

| 2) Stainless steel: 303,304,316L, 17-4(SUS630) etc. | |

| 3) Steel: 4140, Q235, Q345B,20#,45# etc. | |

| 4) Titanium: TA1,TA2/GR2, TA4/GR5, TC4, TC18 etc. | |

| 5) Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc. | |

| 5) Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc. | |

| Finish | Sandblasting, Anodize color, Blackenning, Zinc/Nickl Plating, Polish. |

| Power coating, Passivation PVD, Titanium Plating, Electrogalvanizing. | |

| Electroplating chromium, electrophoresis, QPQ(Quench-Polish-Quench). | |

| Electro Polishing,Chrome Plating, Knurl, Laser etch Logo, etc | |

| Main Equipment | STEP,STP,GIS,CAD,PDF,DWG,DXF etc or samples. |

| Tolerance | +/-0.01mm ~ +/-0.05mm |

| Surface roughness | Ra 0.1~3.2 |

| Inspection | Complete inspection lab with Micrometer, Optical Comparator, Caliper Vernier,CMM. |

| Depth Caliper Vernier, Universal Protractor, Clock Gauge, Internal Centigrade Gauge | |

| Capacity | CNC turning work range: φ0.5mm-φ150mm*300mm. |

| CNC milling work range: 510mm*1020mm*500mm. |

Key Features

- Exceptional durability and strength

- Precise threading for secure fastening

- Corrosion-resistant options available

- Custom designs for unique applications

Surface Treatment

To enhance the performance and longevity of our products, we offer various surface treatments:

- Anodizing: Ideal for aluminum inserts, providing excellent corrosion resistance and a decorative finish.

- Electroplating: Available in zinc, nickel, or chrome for improved durability and appearance.

- Passivation: Enhances corrosion resistance for stainless steel inserts.

- Heat treatment: Improves hardness and wear resistance for specific applications.

Drawing Guide

Our engineering team works closely with clients to develop custom products designs. We accept:

- 2D and 3D CAD files

- Detailed technical drawings

- Existing samples for reverse engineering

Our experts can assist with material selection, structural optimization, and design recommendations to ensure your products meet all specifications and performance requirements.

Production Process

- Material selection and inspection

- CNC machining (turning, milling, drilling)

- Threading and tapping

- Heat treatment (if required)

- Surface finishing

- Quality control and inspection

- Packaging and shipping

Quality Certification

Dongguan Junsion Precision Hardware Co., Ltd. is committed to maintaining the highest quality standards. Our Insert Parts manufacturing processes are certified to:

- ISO 9001:2015 Quality Management System

- RoHS compliance for environmental safety

We conduct rigorous quality control measures throughout the production process, including:

- Incoming material inspection (IQC)

- In-process quality control (IPQC)

- Final quality check (OQC)

Our state-of-the-art testing equipment, including 2.5D projectors, hardness testers, and salt spray machines, ensures that every Insert Part meets or exceeds international standards.

Shipping and Delivery

We understand the importance of timely delivery in your manufacturing processes. Our efficient production scheduling and reliable logistics network allow us to offer:

- Sample delivery within 3 days

- Mass production orders within 7-15 days

We ship globally, with extensive experience serving clients in Europe, North America, Southeast Asia, and Japan.

Why Choose Us?

- Advanced precision machining capabilities

- Customizable solutions for your specific needs

- Wide material selection and surface treatment options

- Fast turnaround times

- Strict quality control system

- Extensive industry experience and global reach

- Customer-centric approach and responsive communication

FAQ

Q: What materials do you use for the products?

A: We offer products in various materials, including stainless steel, aluminum, copper, carbon steel, and titanium.

Q: Can you produce custom products designs?

A: Yes, we specialize in custom solutions. Our engineering team can work with your drawings or samples to create products that meet your exact specifications.

Q: What is the minimum order quantity (MOQ) for the products?

A: Our MOQ varies depending on the complexity and specifications of the products. Please contact us for a personalized quote.

Q: Do you offer bulk pricing for large orders?

A: Yes, we offer competitive volume discounts for bulk orders. Contact our sales team for detailed pricing information.

Contact & Support

Ready to elevate your manufacturing process with our precision Insert Parts? Contact Dongguan Junsion Precision Hardware Co., Ltd. today for expert advice, custom solutions, and competitive pricing.

Email: Lock@junsion.com.cn, echo@junsion.com.cn, or evelyn@junsion.com.cn.

Trust Dongguan Junsion Precision Hardware Co., Ltd. for all your products needs. Let's build a lasting partnership for your manufacturing success.

_1755501421989.jpg)

_1755501421843.jpg)

_1755501421771.jpg)

_1755742565833.jpg)